Centrifugal blower

a centrifugal blower and centrifugal technology, applied in the direction of liquid fuel engines, marine propulsion, vessel construction, etc., can solve the problems of unstable flow, worse wind noise, and airflow disturbance, and achieve the effect of reducing wind nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

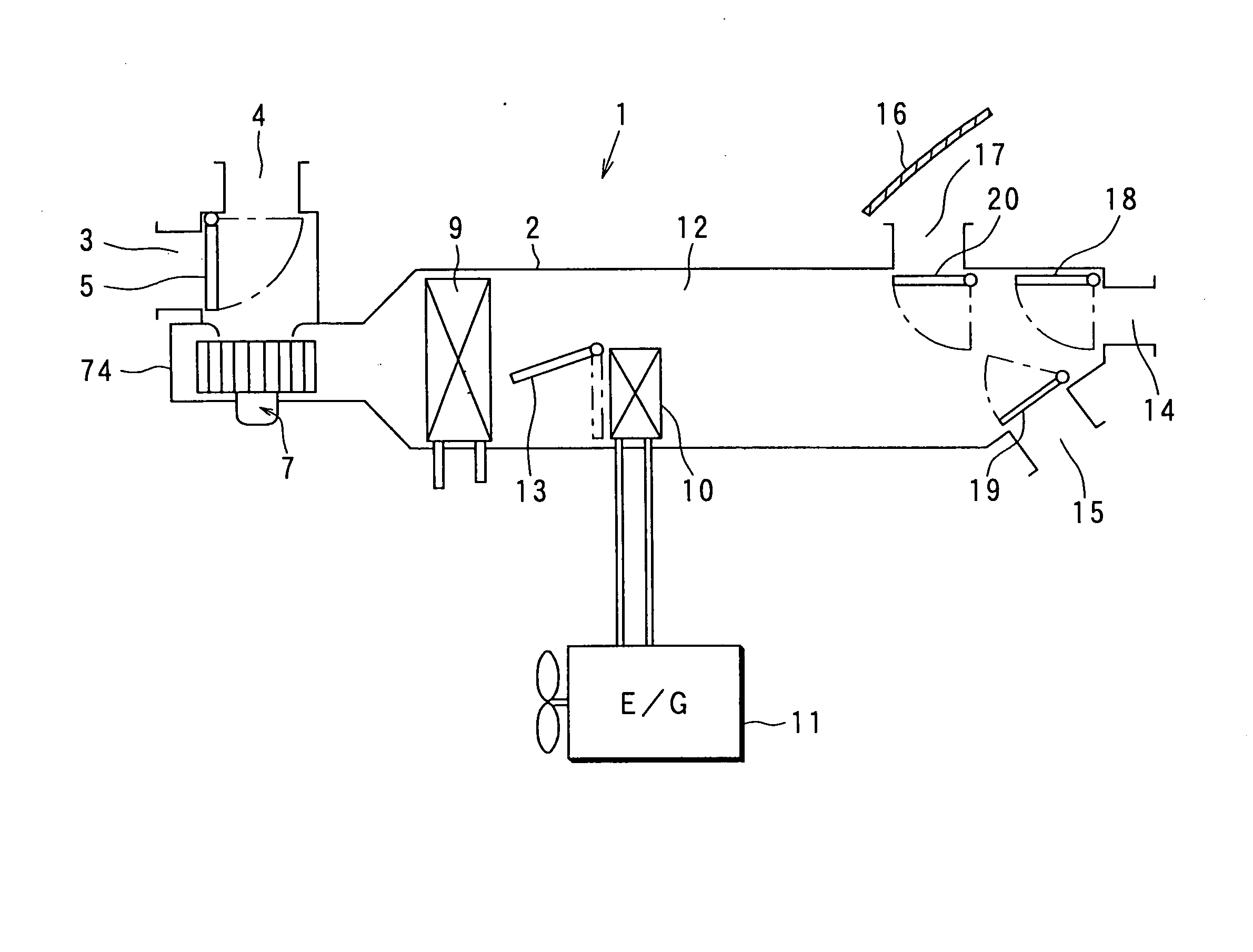

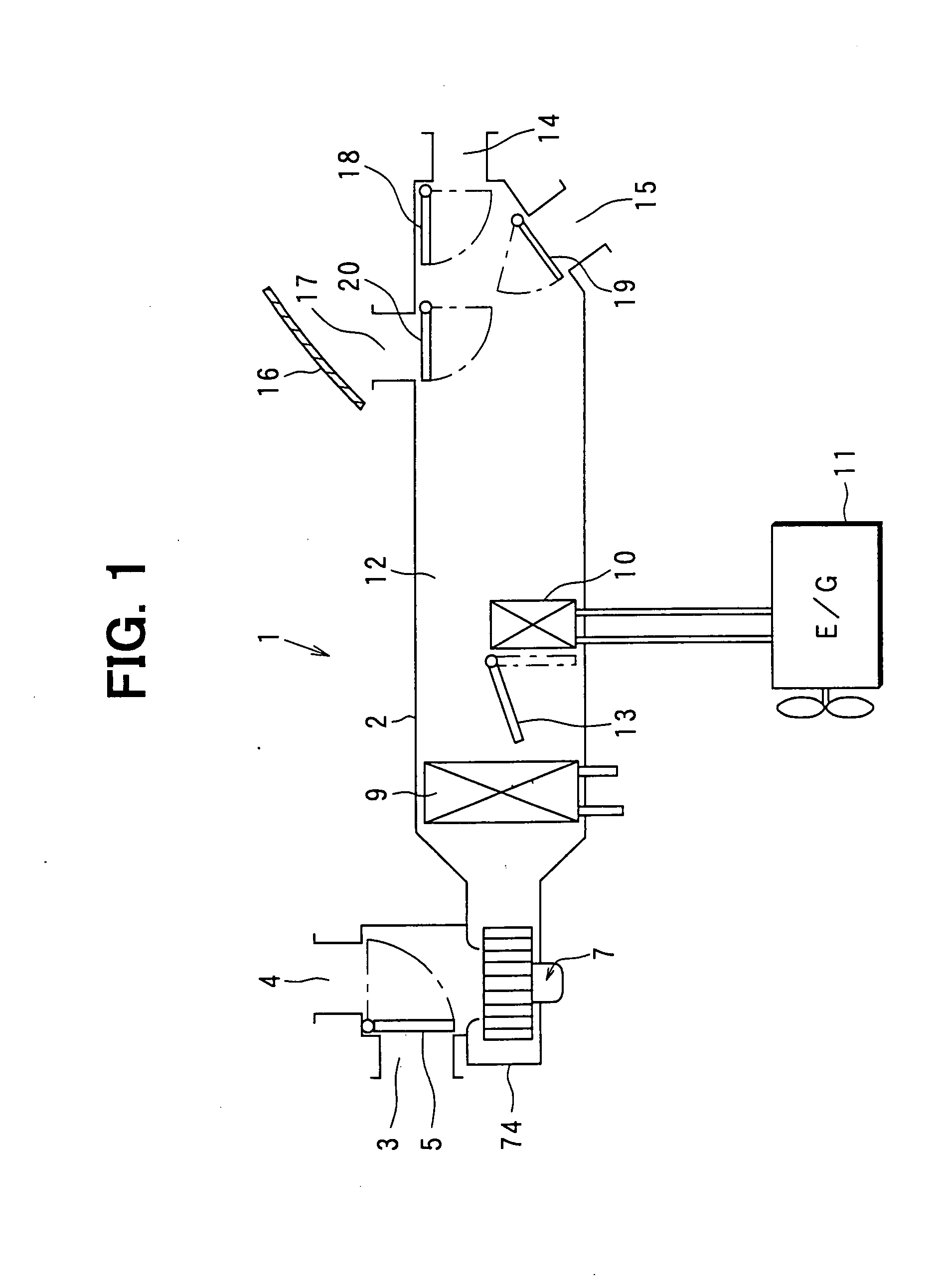

[0053] A centrifugal blower is applied to a blower in a vehicle air-conditioning apparatus according to a first embodiment of the present invention. FIG. 1 is a schematic drawing of a vehicle air-conditioning apparatus 1 for a vehicle equipped with a water-cooled engine, and the centrifugal blower (abbreviated as a blower hereafter) according to the present invention.

[0054] An internal air intake opening 3 for taking in cabin air, and an external air intake opening 4 for taking in outside air are formed on an airflow upstream side of an air conditioner casing 2 forming an airflow passage. An intake-opening switching door 5 is provided for selectively opening and closing the intake openings 3 and 4. Drive means such as a servomotor, or manual operation opens and closes the intake-opening switching door 5.

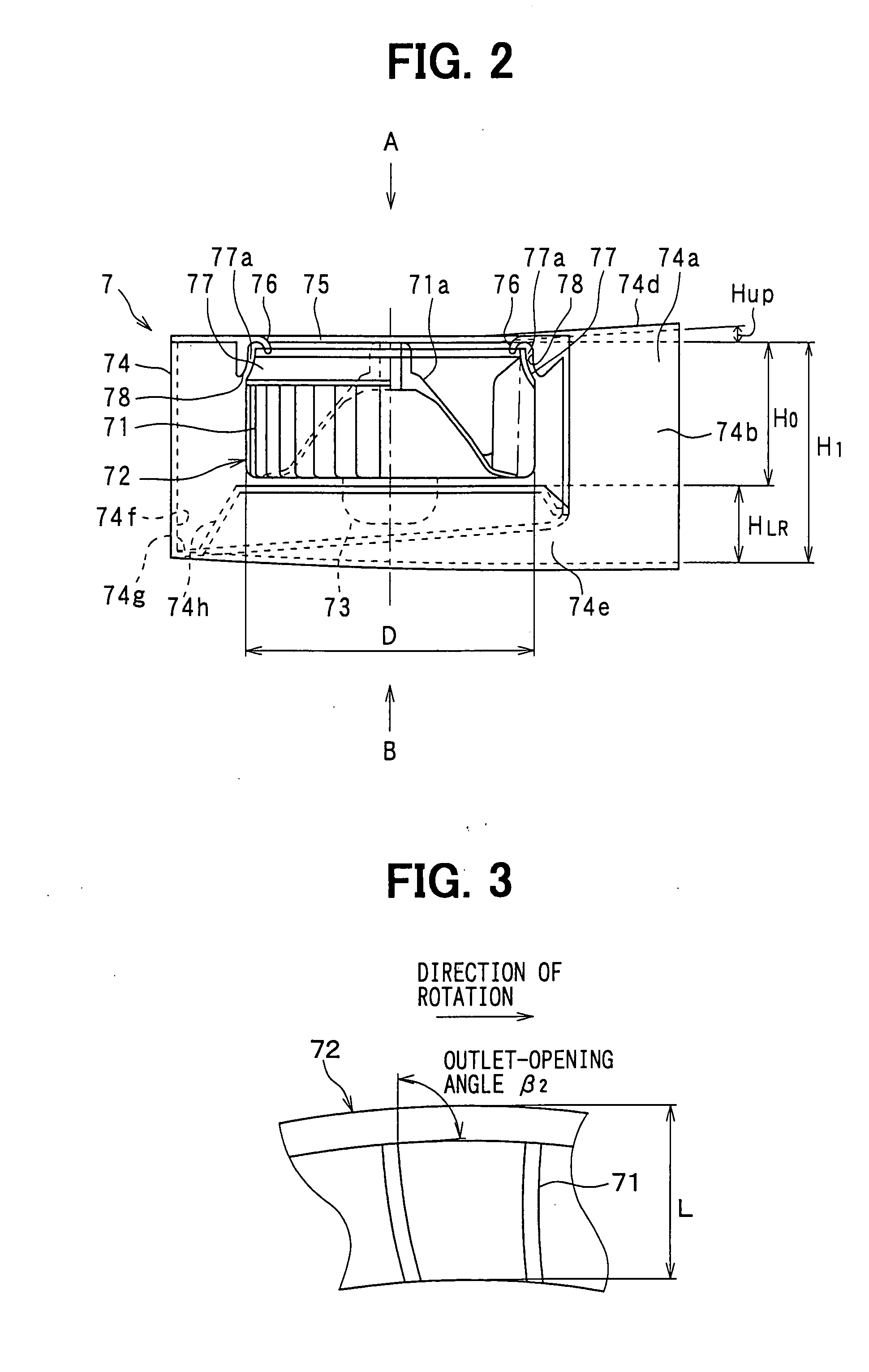

[0055] A filter (not shown) for removing dust in the air, and a blower 7 according to the present invention are provided on the airflow downstream side of the intake-opening switch...

second embodiment

[0085] The cross-section of the flow passage 74a can be set as an approximately rectangular shape whose corners are arcs in a second embodiment as shown in FIG. 11. With this structure, since an unstable swirling flow is prevented from being generated at the corners of the airflow passage 74a, and simultaneously, a generated swirling flow is smoothly circulated, the swirling flow is stabilized, and wind noise is reduced. It is preferable that the curvature radius of the arcs is properly set according to the radius of the swirling flow generated in the airflow passage 74a.

third embodiment

[0086]FIG. 12 shows a third embodiment of the present invention. A protrusion 74j protruding toward the fan 72 is formed along almost the entire airflow passage 74a on the inner wall of the outer peripheral portion of the casing 74, and the cross-section of the protrusion 74j is approximately triangular (wedge-shaped) and protrudes toward the fan 72 when the protrusion 74j is seen from a primary flow direction of the air flowing through the airflow passage 74a.

[0087] With this structure, since the protrusion 74j is provided at a part with which air with the highest flow rate of the air blown out from the fan 72 collides, the air blown out from the fan 72 is easily divided into the side of the inlet opening 75 and the opposite side. This promotes the generation of swirling flow to reduce wind noise generation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com