Centrifugal fan

一种离心风扇、扇框的技术,应用在用于弹性流体的泵送装置的部件、非变容式泵、泵装置等方向,能够解决传统离心风扇900风量限制、气流阻滞、气流不能被顺畅地引导等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

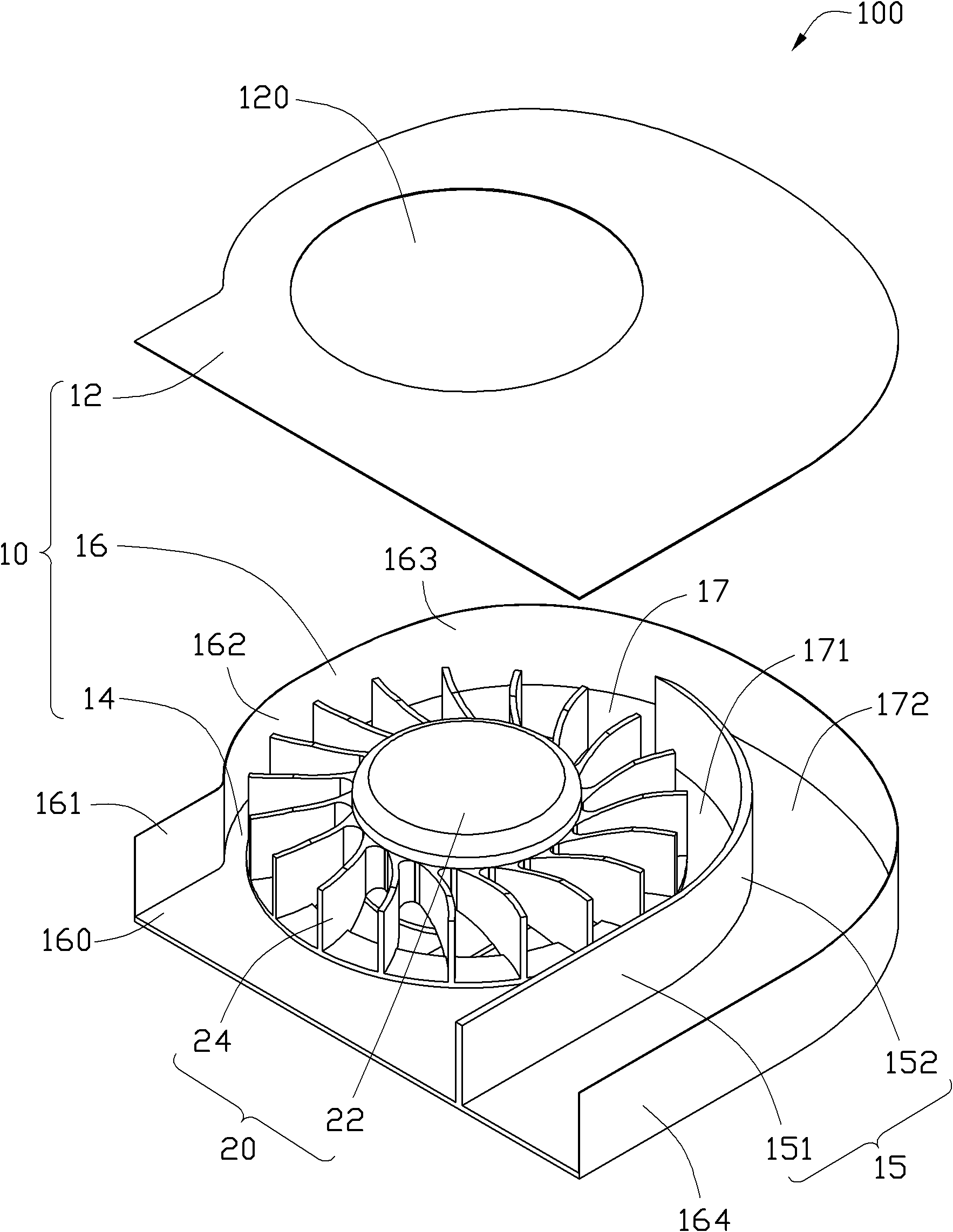

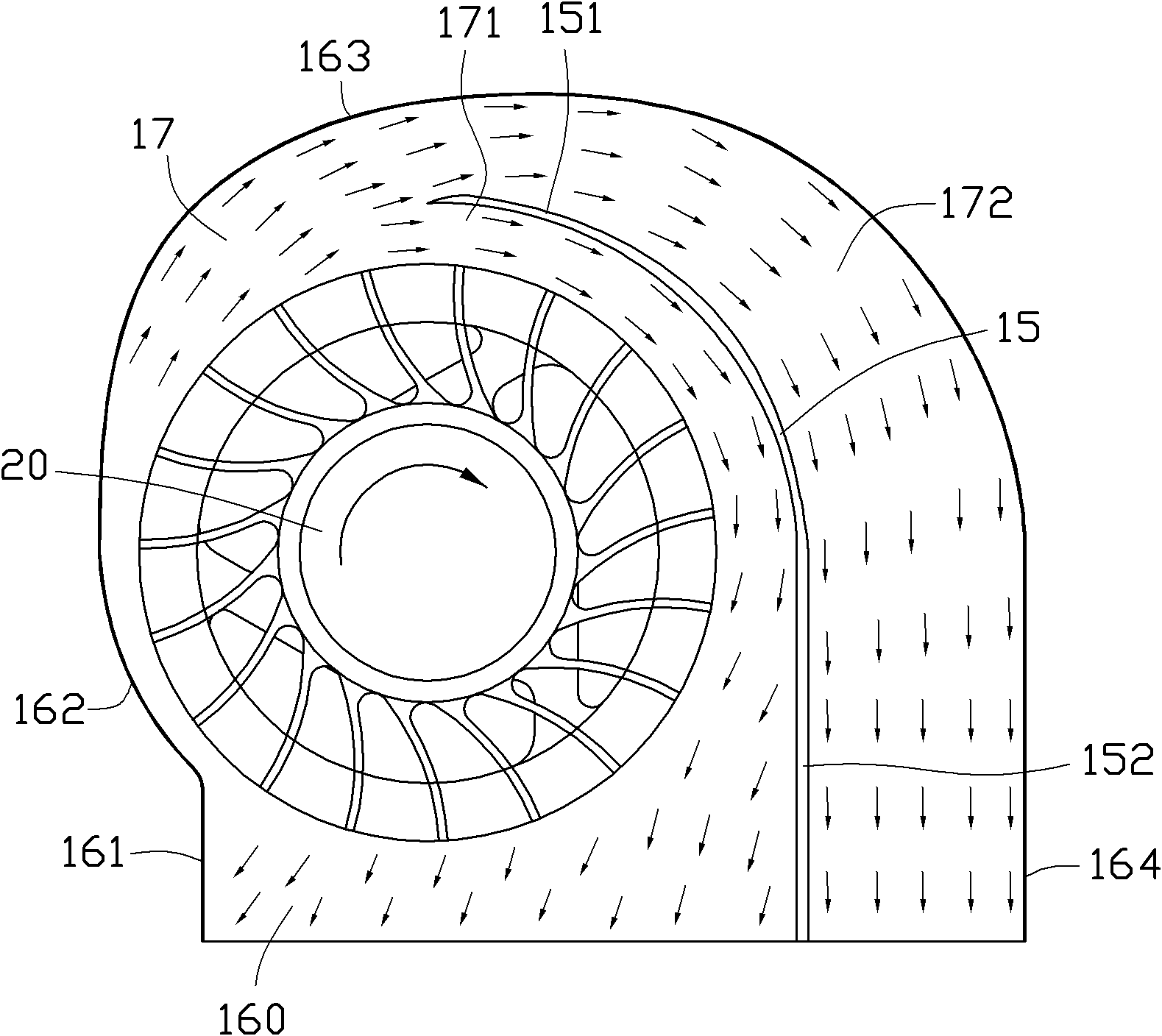

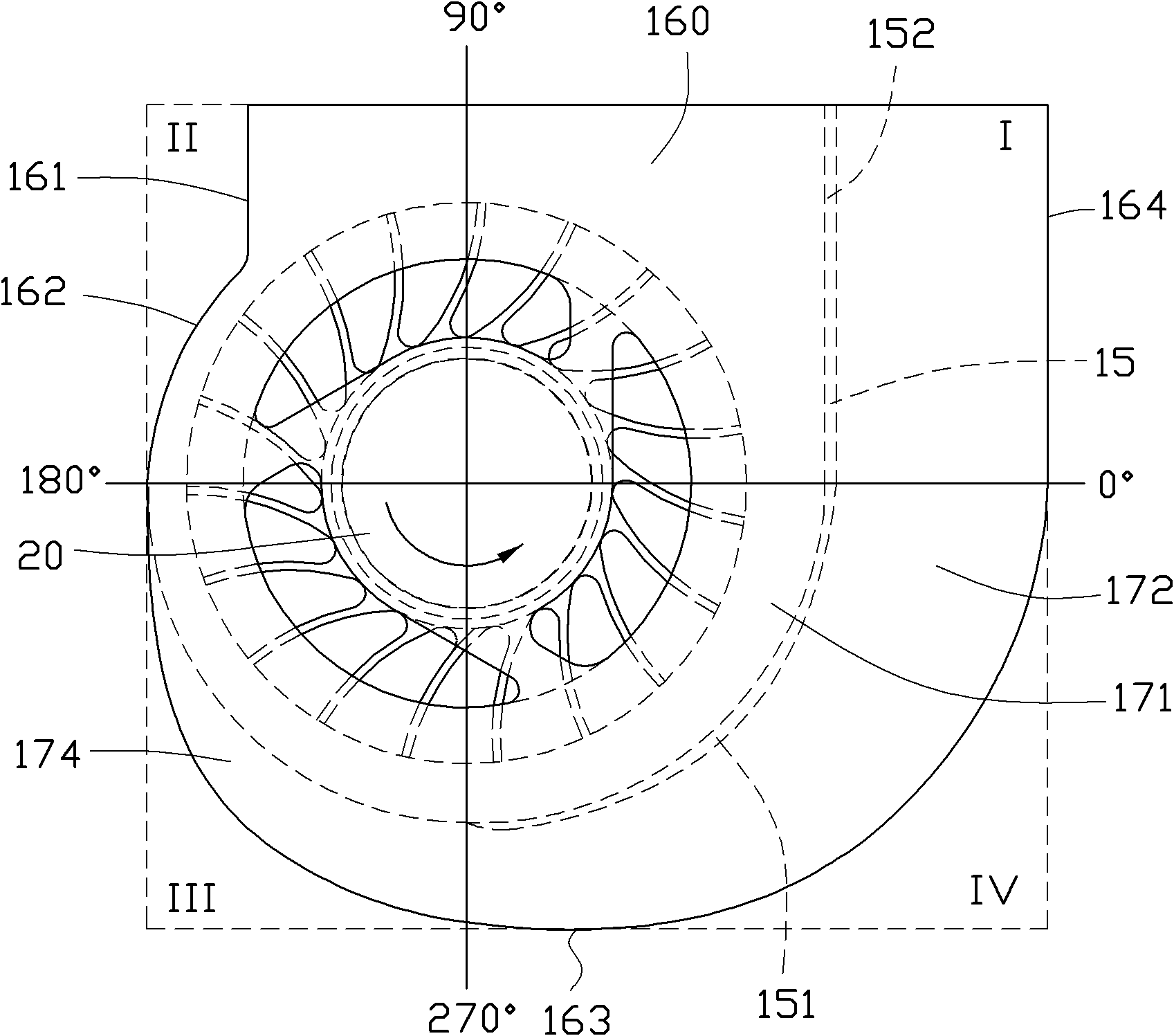

[0040] see figure 1 and figure 2 . The centrifugal fan 100 includes a fan frame 10 and an impeller 20 accommodated in the fan frame 10 . The impeller 20 includes a hub 22 and a plurality of blades 24 radially extending from the hub 22 . The fan frame 10 includes a top plate 12 , a bottom plate 14 opposite to the top plate 12 , and a scroll-shaped side wall 16 connected between the top plate 12 and the bottom plate 14 . The top plate 12 , the bottom plate 14 and the side wall 16 enclose and form an accommodating space, and the impeller 20 is accommodated in the accommodating space.

[0041] An air inlet 120 is formed in the center of the top plate 12 . The impeller 20 is rotatably mounted on the bottom plate 14 and faces the air inlet 120 . The side wall 16 vertically surrounds the outer periphery of the bottom plate 14 . In this embodiment, the side wall 16 is integrally formed with the bottom plate 14 . Of course, the side wall 16 and the bottom plate 14 can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com