High full-voltage large-flow centrifugal blower with slant-wheel disk front-bent impeller

A centrifugal fan and large flow technology, applied in mechanical equipment, radial flow pumps, machines/engines, etc., can solve problems such as low operating efficiency and high energy consumption, and achieve reduced flow loss, reduced noise, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of this patent is described in detail below in conjunction with technical scheme and accompanying drawing.

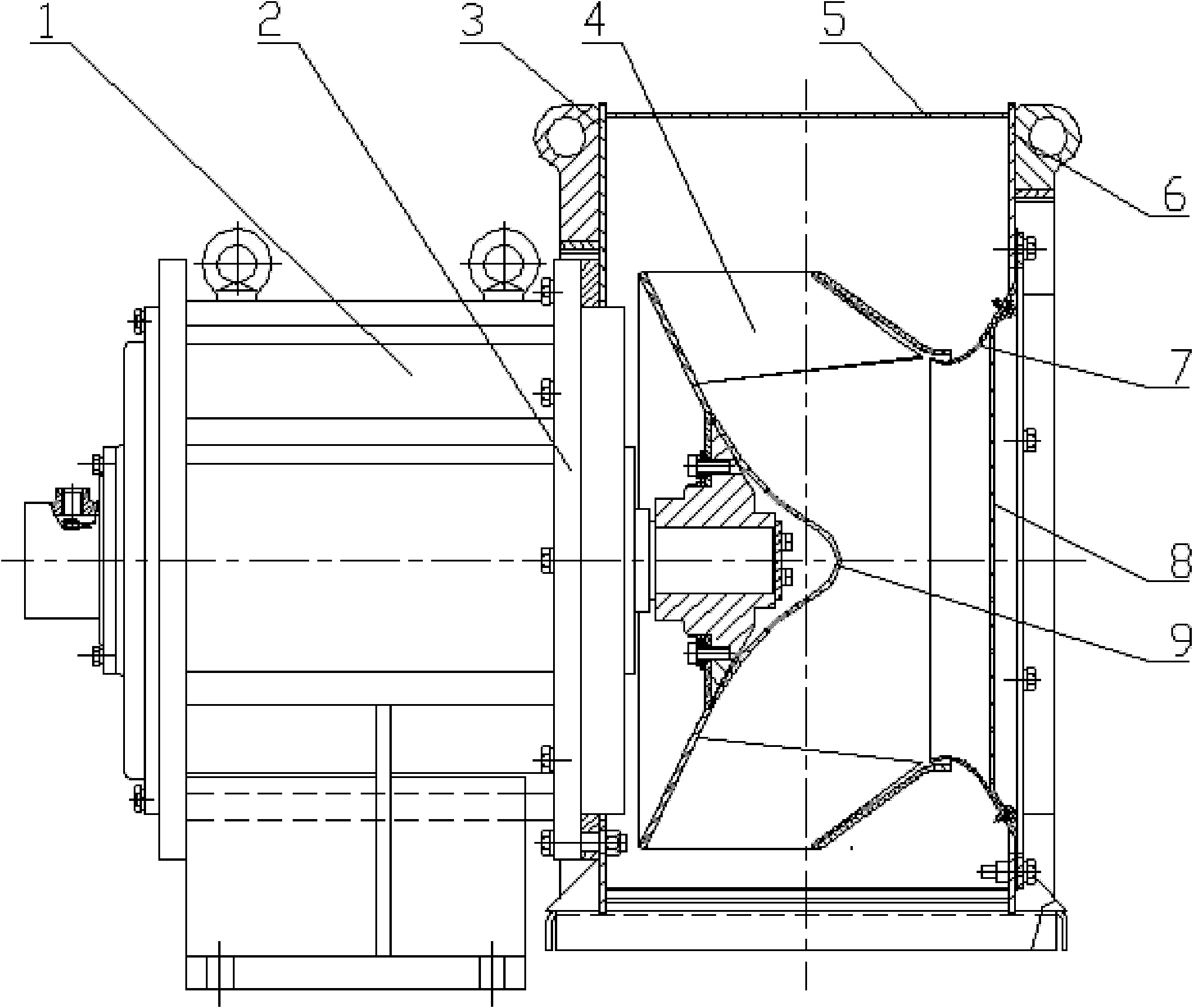

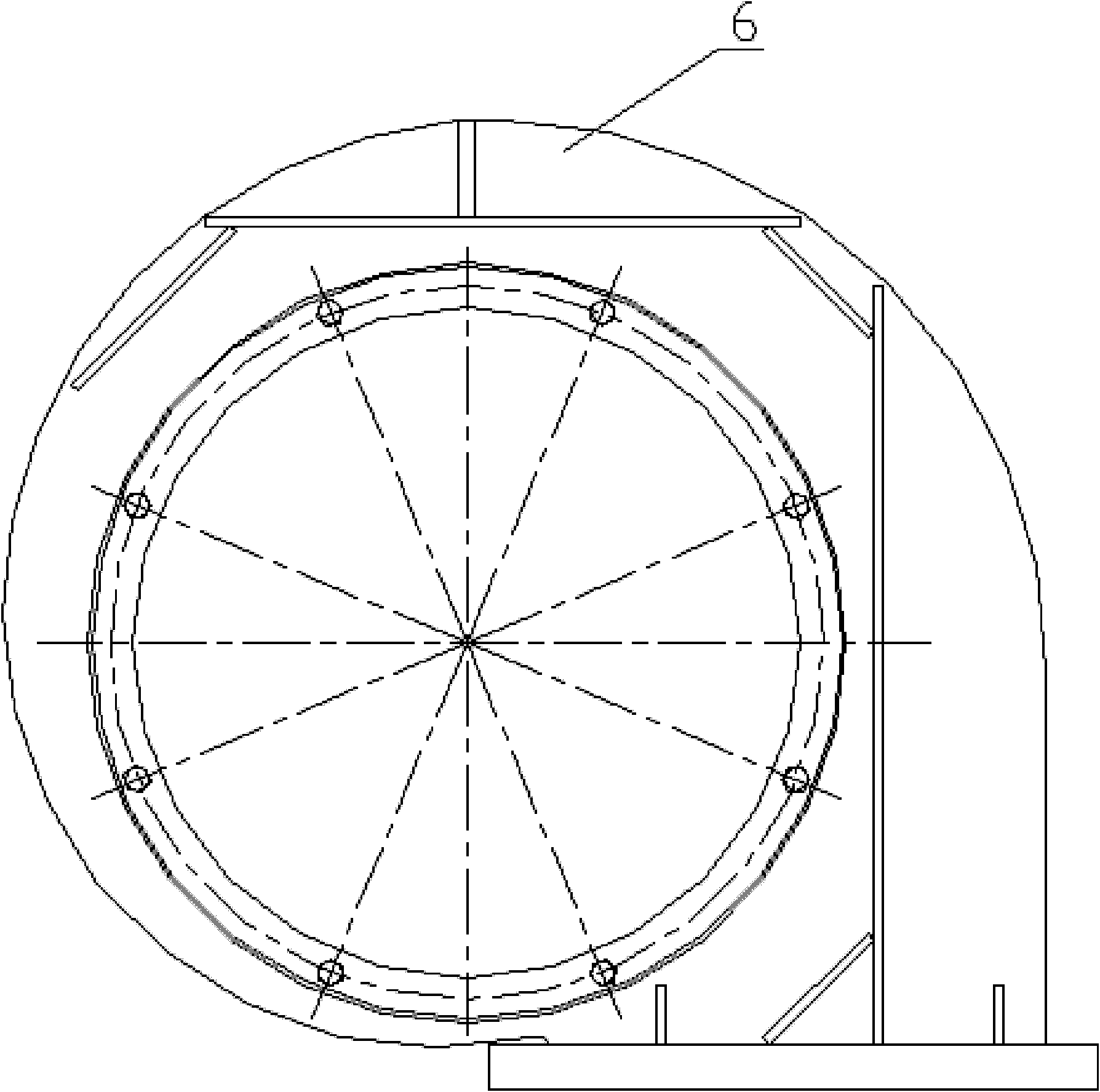

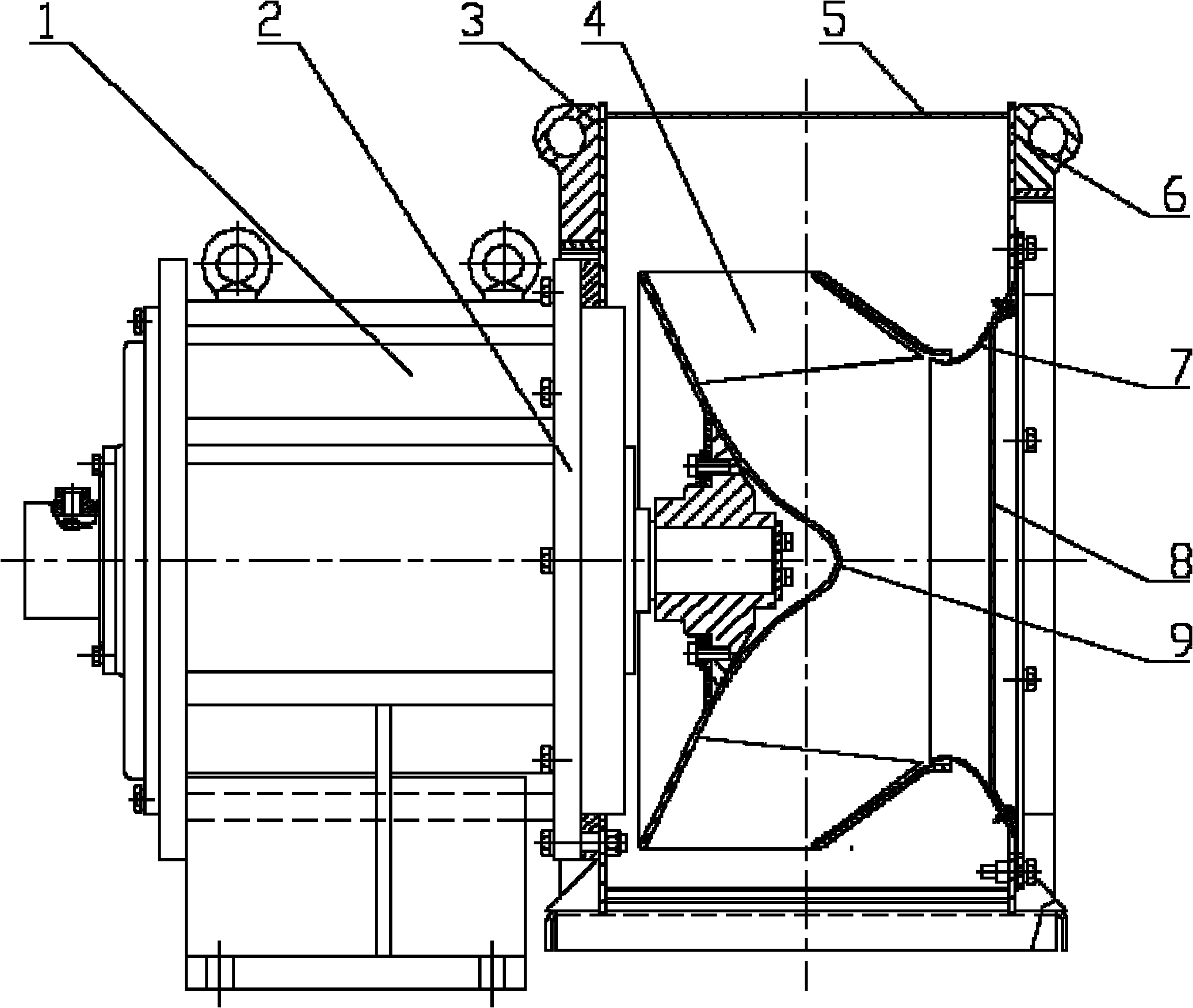

[0018] Such as figure 1 , figure 2 As shown, a high total pressure and large flow inclined wheel disk forward curved impeller centrifugal fan of this patent consists of a motor 1, a bracket 2, a rear side plate 3, an impeller 4, an exhaust volute 5, a front side plate 6, and a cone arc Shaped inlet guide pipe 7, protective net 8 and inlet guide cover 9 are formed. Wherein the impeller 4 adopts a slanted wheel disc, and a conical inlet shroud 9 is installed at the wheel hub, and compared with the traditional forward curved impeller of the same type that mostly adopts many short blades, the impeller 4 in this patent adopts 36 arc-shaped long blades. The number of blades is obviously reduced by about half, and the inlet side of the blades has a relatively large extension to the inlet of the impeller 4. The exhaust volute 5 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com