A large flow and large aspect ratio blade axial flow fan

A technology with large aspect ratio and blade shaft, which is used in the field of cooling ventilation and large-flow axial flow fans. It can solve the problems of overloading the fan drive motor and failing to meet energy-saving requirements, and achieve a uniform and stable inlet flow field and a simple airfoil. And effective, large flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

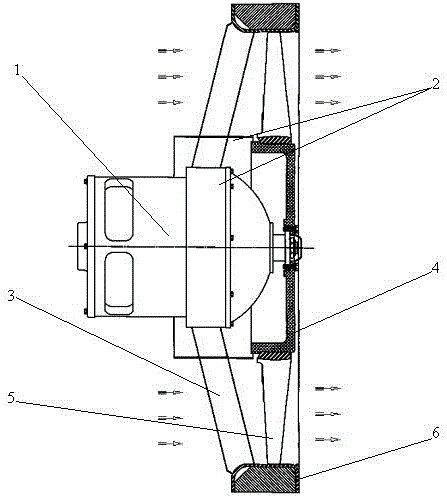

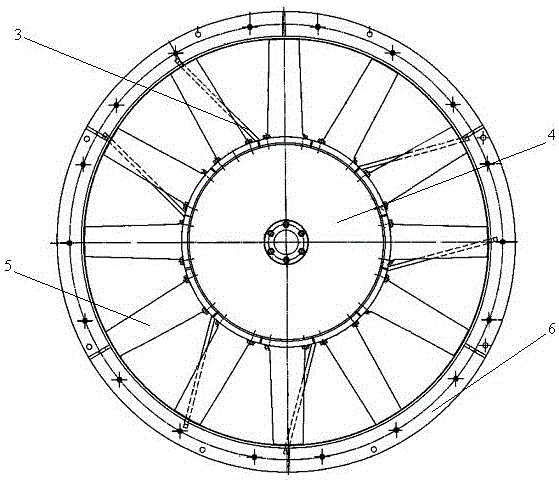

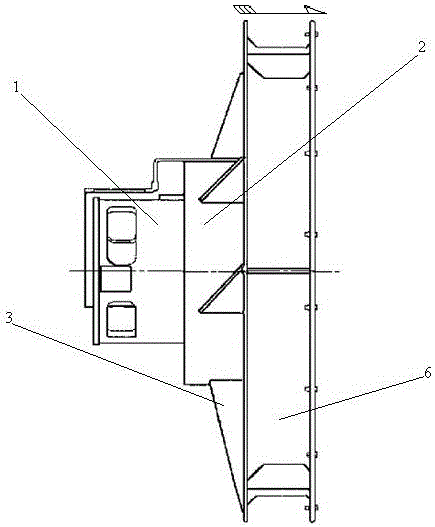

[0021] Such as figure 1 The blade-type axial flow fan with large flow and large aspect ratio shown in -3 is composed of a driving motor 1 , an inner support ring 2 , a support plate 3 , a hub 4 , blades 5 and a connecting duct 6 . The drive motor 1 is front mounted and connected to the inner support ring 2 by bolts, the inner support ring 2 is fixed on the support plate 3 by welding, and the support plate 3 is fixed on the connecting air duct 6 by welding, so that the drive motor 1 and the connection The relative position of air duct 6 has been fixed; blade 5 is connected with wheel hub 4 by bolts to form a rotatable impeller, and wheel hub 4 is connected with the shaft of drive motor 1 by coupling, so that blade 5 and wheel hub 4 are connected with respect to the shaft of air duct 6. The position is fixed, so that the relative positions of all parts of the whole fan are fixed. In this example, the impeller blade 5 adopts 12 pieces, and the blade 5 is as Figure 4 All shown ...

Embodiment 2

[0024] Large flow rate and large aspect ratio blade type axial flow fan, the basic structure is the same as that of embodiment 1. In this example, 10 impeller blades 5 are used, and the blades are all large aspect ratio blades, with an average aspect ratio of 2 and 5 blade roots. The installation angle is 25°, the joint between the blade and the tenon is rounded, the chamfering radius is 10m, and there are 3 pieces (three sets) of equal-thickness support plates 3 with diversion function welded between the connecting air duct 6 and the inner support ring 2 .

Embodiment 3

[0026] Large flow and large aspect ratio blade type axial flow fan, the basic structure is the same as that of embodiment 1. In this example, 15 impeller blades 5 are used, and the blades are all large aspect ratio blades, with an average aspect ratio of 3.5 and 5 blade roots. The installation angle is 35°, the joint between the blade and the tenon is rounded, and the chamfering radius is 25m. There are 9 pieces (three sets) of equal-thickness support plates 3 with diversion function welded between the connecting air cylinder 6 and the inner support ring 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com