Semiconductor cold and hot oven

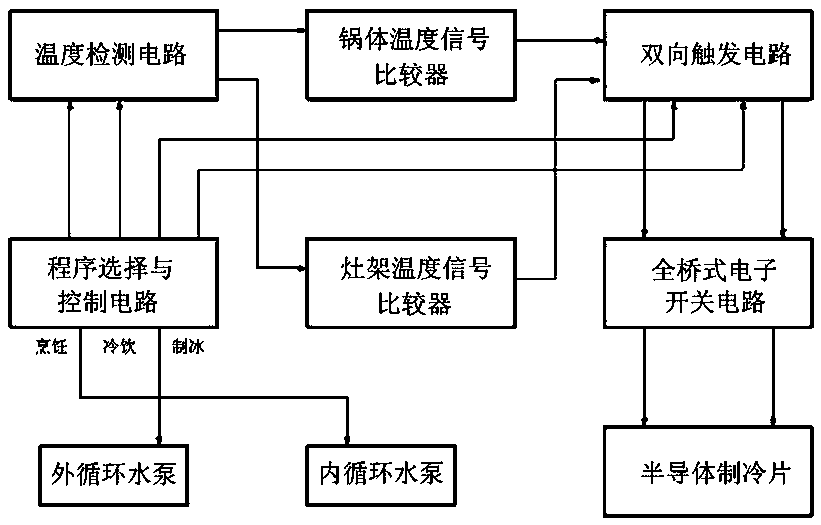

A semiconductor, cooling and heating technology, applied in the field of civilian cookers, can solve the problems that the cooling temperature is difficult to break through below 0°C, it is difficult to achieve continuous and efficient heating, and the heating efficiency is reduced, achieving significant energy saving effects and fast heating speed , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

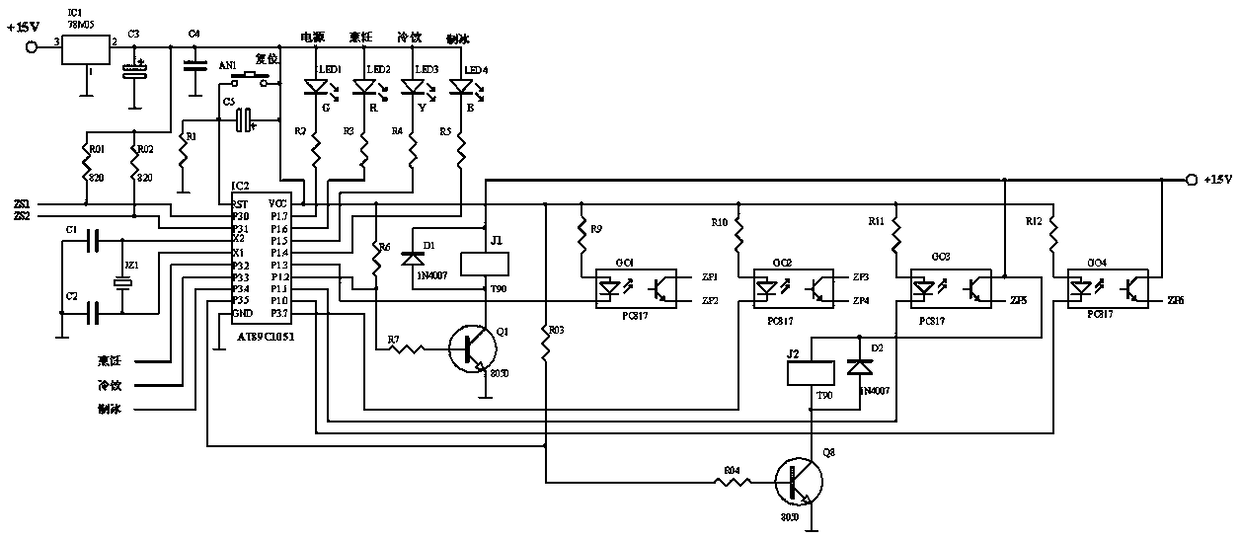

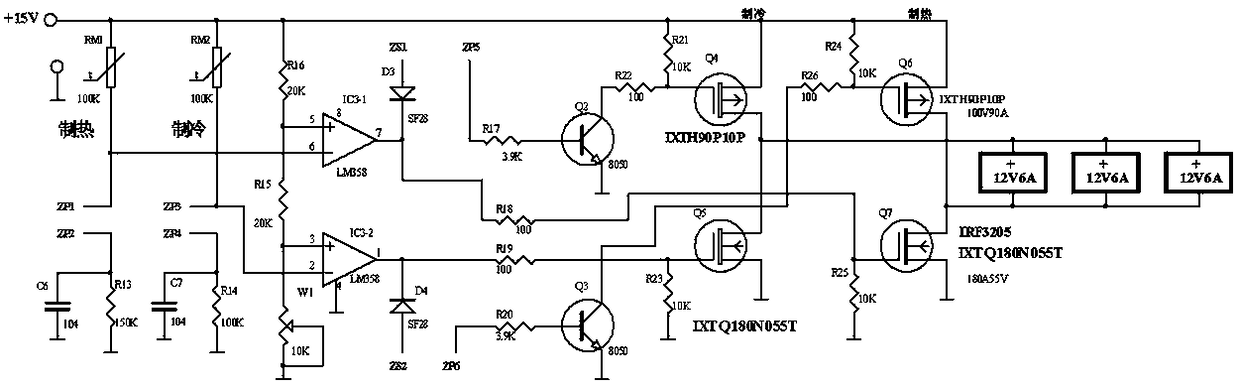

Method used

Image

Examples

Embodiment Construction

[0037] Such as figure 1 , figure 2 As shown, the pot body 1 is a frying pan, its inner wall is spherical, and the lower section of the outer wall is a flat-bottomed edge platform, which can be cast from aluminum alloy (aviation aluminum). On the bottom plane of the pot body 1, a rectangular semiconductor cooling chip 6 is attached through high-quality thermally conductive silicone grease, and a rectangular semiconductor cooling chip 6 is attached to each trapezoidal plane corresponding to the lower edge of the pot body 1. Each semiconductor cooling chip High-quality heat-conducting silicone grease is coated between the cooling sheet and the pot body 1 to ensure lossless conduction of cold and heat energy. If the pot body 1 is selected as a hexagonal platform shape, seven semiconductor cooling chips are arranged on the pot body 1, and the seven semiconductor cooling chips are connected in parallel. The specification of the semiconductor refrigeration chip 6 is 40*40mm, 12V 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com