Impinging stream high-shear reactor for liquid-liquid quick mixing and reaction

A high-shear reactor, the technology of the reactor, applied in the direction of chemical methods, chemical/physical/physical-chemical stationary reactors, chemical instruments and methods for reacting liquids with liquids, etc., can solve the limitation of high shear technology application range, no heat exchange function, and inability to mix and react with thermal effects, to reduce the formation of local hot spots or cold spots, promote mixing, and reduce the incidence of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

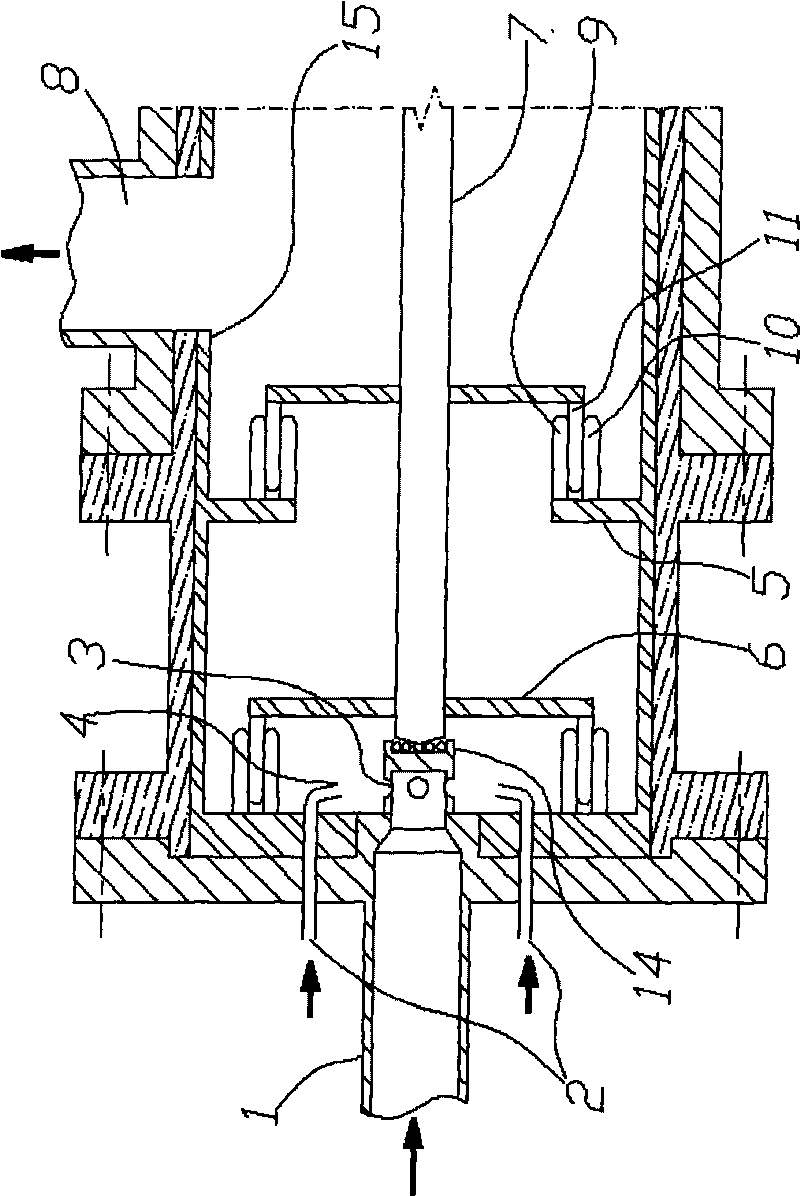

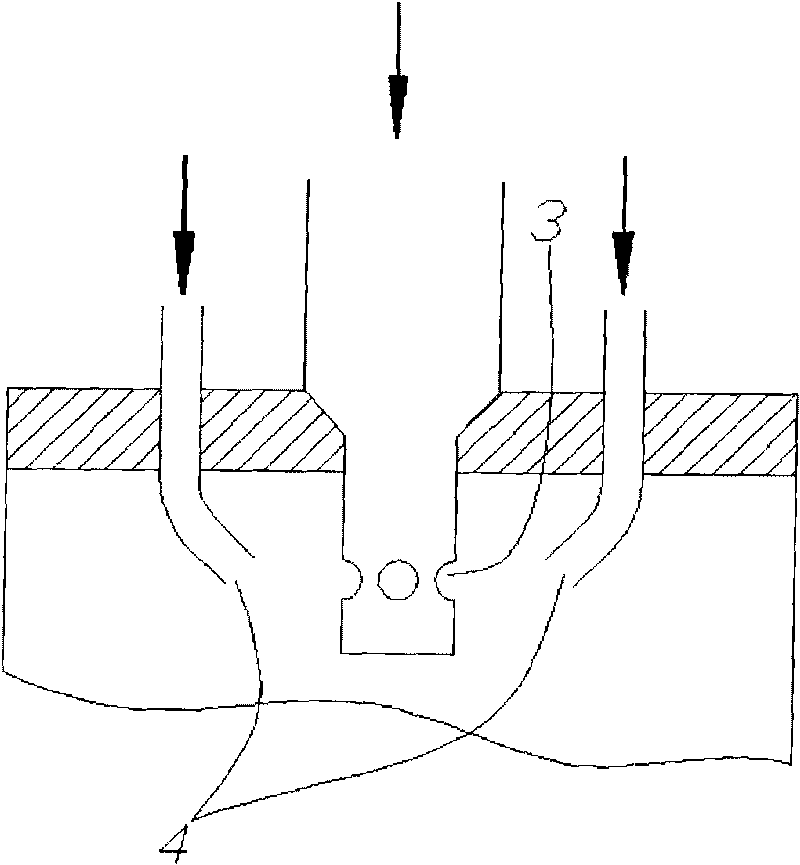

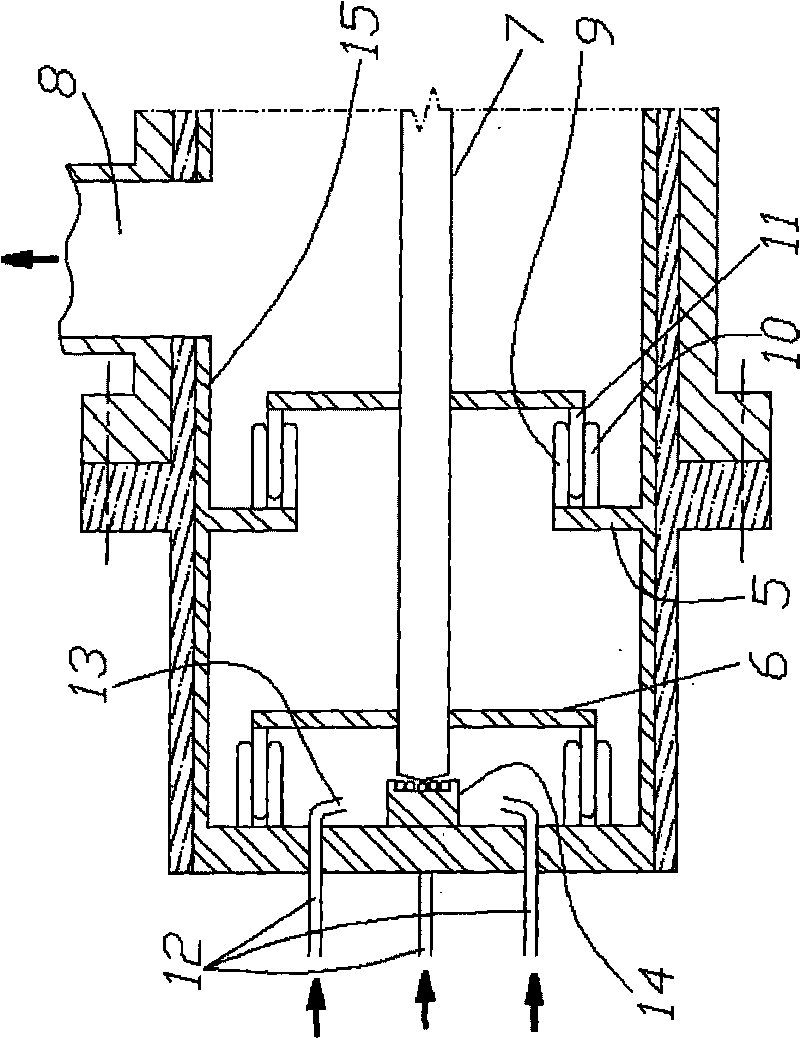

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] An impingement flow high shear reactor for liquid-liquid rapid mixing and reaction, comprising a cylindrical reactor shell 15, a rotor 11, a stator and a main drive shaft 7, and the center of one end wall of the reactor shell is provided with a The first feeding pipe 1, one end of the first feeding pipe located in the shell of the reactor is a blind end, and a discharge hole 3 of the first feeding pipe is provided near the blind end, and the discharging hole of the first feeding pipe is The pore diameter can be selected from 3 to 10 mm; a second feeding pipe 2 is arranged around the first feeding pipe, the discharge port 4 of the second feeding pipe is located in the shell of the reactor, and the discharging port of the second feeding pipe is connected with the first feeding pipe. The discharge holes of a feeding pipe are arranged oppositely; the blind end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com