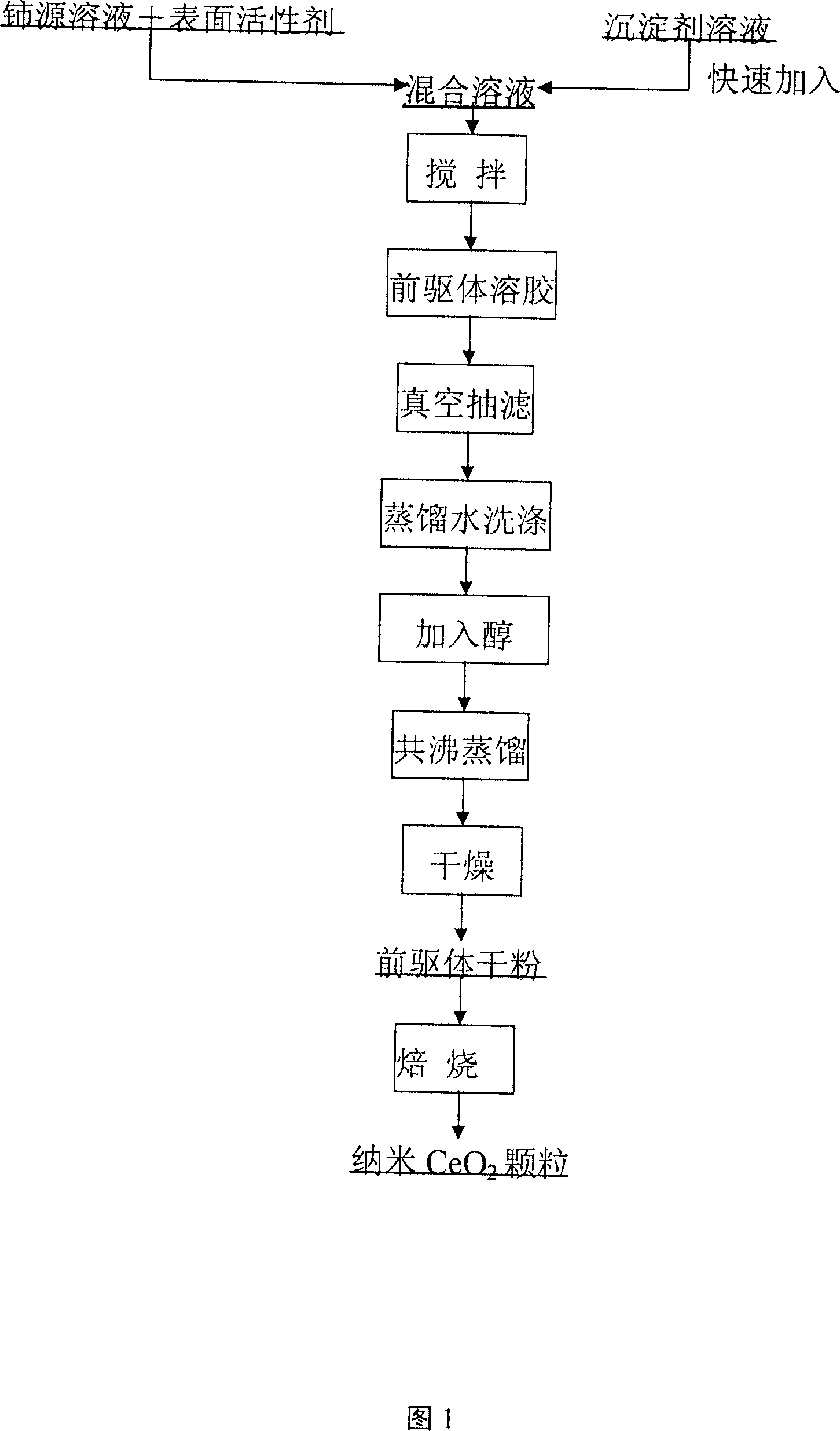

Process for preparing nanometer cerium dioxide

A nano-ceria, cerium salt technology, applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, to achieve the effect of reducing cost, large activity and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

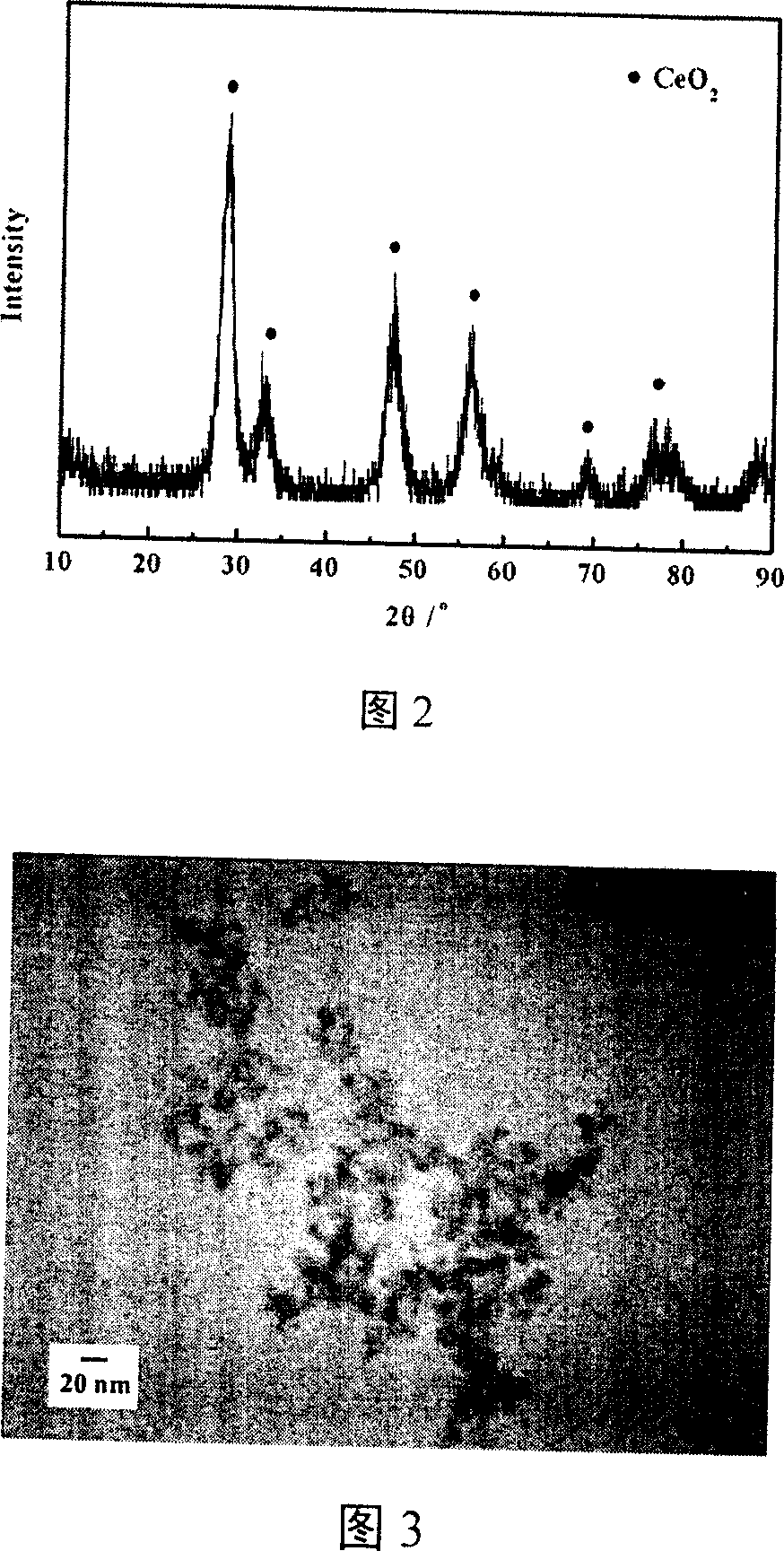

Embodiment 1

[0021] Weigh Ce(NO 3 ) 3 ·6H 2 O 8.68g, be made into 0.1mol / L solution of 100ml, and add 1gPEG4000 wherein; Weigh (NH 4 ) 2 CO 3 ·H 2 O 5.13g, made into 150ml of 0.1mol / L solution. The prepared two solutions were preheated at 40°C for 10 min, and then (NH 4 ) 2 CO 3 ·H 2 The O solution was quickly poured into the Ce(NO 3 ) 3 ·6H 2 O mixed solution in a 1L three-neck flask with temperature control, control the pH value of the reaction system to 7-8, and stir the reaction by electric machinery at 800r / min for 10min, and wash the obtained sol twice with deionized water during the vacuum filtration process , the sol after suction filtration is mixed with 20ml n-butanol under strong mechanical stirring to form a suspension, and then the liquid is poured into a three-necked flask of an azeotropic distillation device. When the temperature rises to the water-alcohol azeotropic temperature of 93°C, the The water in the gel is entrained and removed in the form of azeotrop...

Embodiment 2

[0023] Weigh Ce(NO 3 ) 3 ·6H 2 O 8.68g, be made into 0.1mol / L solution of 100ml, and add 1gPEG4000 wherein; Weigh (NH 4 ) 2 CO 3 ·H 2 O 5.13g, made into 150ml of 0.1mol / L solution. At 40°C, the (NH 4 ) 2 CO 3 ·H 2 The O solution was quickly poured into the Ce(NO 3 ) 3 ·6H 2 In the O mixed solution, the pH value of the reaction system was controlled to be 8-9, and the reaction was mechanically stirred at 800rpm for 10 minutes. The obtained precursor sol was washed twice with distilled water during the vacuum filtration process, and the sol after suction filtration was under strong mechanical stirring. Mix with 20ml of isobutanol to form a suspension, then pour the liquid into a three-neck flask of an azeotropic device, heat up to the boiling point of isobutanol above 108°C, take out the gel after reflux for 15 minutes, and put it in a vacuum drying oven to dry at 60°C 3h. The obtained precursor gel powder was calcined in a muffle furnace at 700 °C for 3 hours to ...

Embodiment 3

[0025] Weigh Ce(NO 3 ) 3 ·6H 2 O 8.68g, be made into 0.1mol / L solution of 100ml, and add 1gPEG4000 wherein; Weigh (NH 4 ) 2 CO 3 ·H 2 O 5.13g, made into 150ml of 0.1mol / L solution. At 40°C, the (NH 4 ) 2 CO 3 ·H 2 The O solution was quickly poured into the Ce(NO 3 ) 3 ·6H 2 In the O mixed solution, the pH value of the reaction system was controlled to be 8-9, and the reaction was mechanically stirred at 800rpm for 10 minutes. The obtained precursor sol was washed twice with distilled water during the vacuum filtration process, and the sol after suction filtration was under strong mechanical stirring. Mix with 20ml of n-propanol to form a suspension, pour the liquid into a three-necked flask with an azeotropic device, heat up to the boiling point of isobutanol above 97°C, take out the gel after reflux for 15 minutes, and dry it in a vacuum oven at 60°C for 3 hours . The obtained precursor gel powder was calcined in a muffle furnace at 300 °C for 1 h to obtain ye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com