Process of extracting polymethylene polyphenyl polyamine from its salt water solution

A technique for polymethylene polyphenyl and brine, applied in the field of extracting polymethylene polyphenyl polyamines from brine and extracting polyamines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

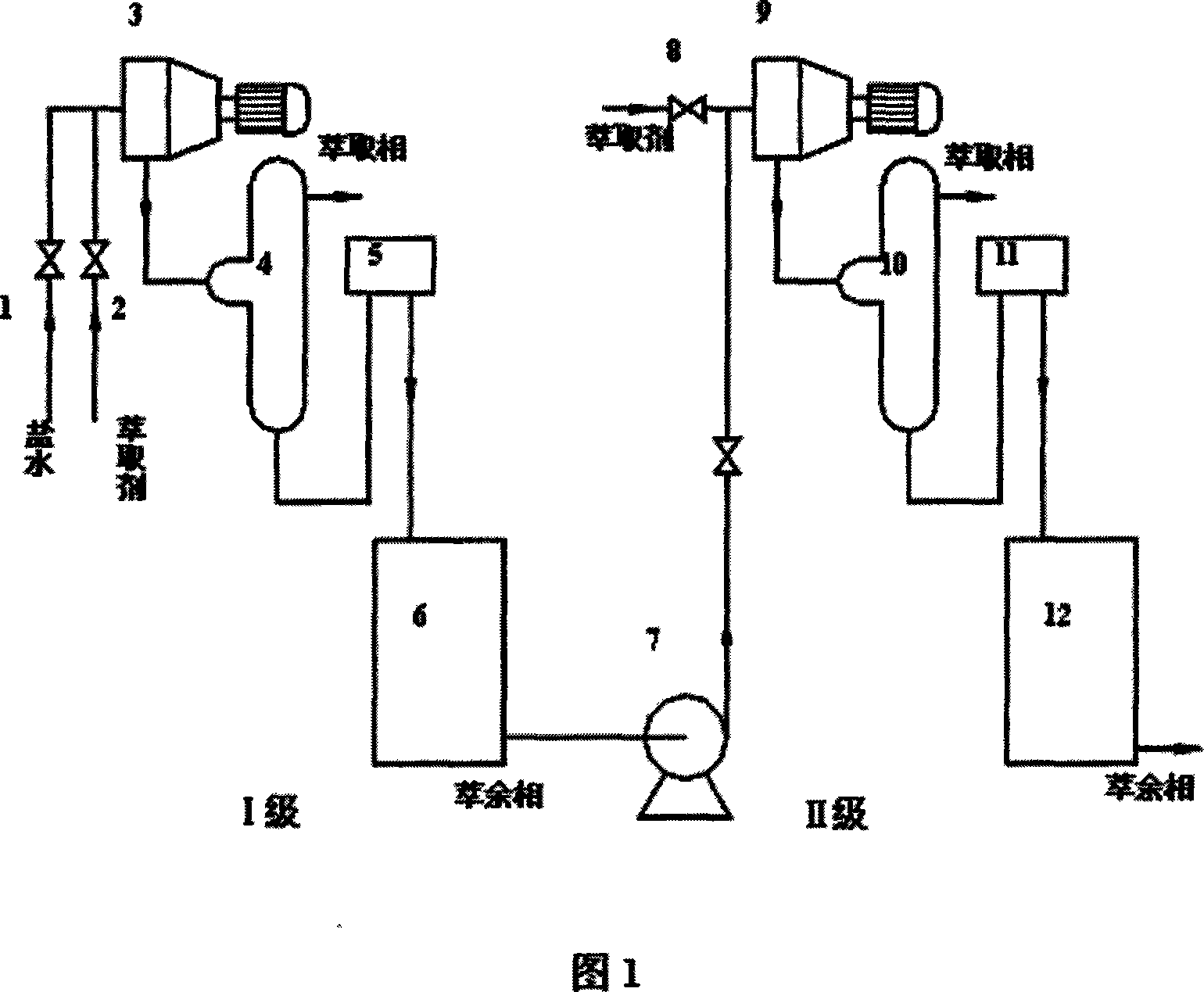

[0027] Turn on the high-gravity rotary bed 3, adjust the rotating speed to 1000 rpm, and adjust the valve 1 to stabilize the flow rate of the saline solution containing polymethylene polyphenyl polyamines at 1000L / h, and the polymethylene polyphenyl polyamines in the saline solution The amine content is 1355mg / L, with aniline (purity 99.5%) as the extractant, the valve 2 is adjusted to stabilize the flow rate of the extractant at 100L / h, and the brine and extractant flow from the inner edge of the supergravity rotating bed rotor to The outer edge flows into the separator 4 through the liquid outlet. Adjust the liquid level in the separator 4 so that the residence time of the liquid in the separator 4 is 1.5 hours, the solution is layered, the upper part is the extractant phase, and the lower part is the brine phase. The extraction phase is drawn from the upper part of the separator, and the raffinate phase is drawn from the lower part of the separator 4 and flows into the tank...

Embodiment 2

[0029] Open the high-gravity rotary bed 3, adjust the rotating speed to 500 rpm, and adjust the valve 1 to stabilize the flow rate of the saline solution containing polymethylene polyphenyl polyamines at 100L / h, and the polymethylene polyphenyl polyamines in the saline solution The amine content is 1055mg / L, with p-methylaniline (purity is 99%) as extraction agent, regulating valve 2 makes the extraction agent flow rate stable at 900L / h, brine and extraction agent are produced by the supergravity rotating bed rotor under centrifugal force The inner edge flows to the outer edge, through the liquid outlet into the separator 4 . Adjust the liquid level in the separator 4 so that the residence time of the liquid in the separator 4 is 1.0 hour, the solution is layered, the upper part is the extractant phase, and the lower part is the brine phase. The extraction phase is drawn from the upper part of the separator, and the raffinate phase is drawn from the lower part of the separator 4...

Embodiment 3

[0031] Turn on the high-gravity rotary bed 3, adjust the rotating speed to 1000 rpm, and adjust the valve 1 to stabilize the flow rate of the saline solution containing polymethylene polyphenyl polyamines at 1000L / h, and the polymethylene polyphenyl polyamines in the saline solution The amine content is 1135mg / L, with aniline (purity 99.5%) as the extractant, the valve 2 is adjusted to stabilize the flow rate of the extractant at 200L / h, the brine solution and the extractant flow from the inner edge of the supergravity rotating bed rotor to the The outer edge flows into the separator 4 through the liquid outlet. Adjust the liquid level in the separator 4 so that the residence time of the liquid in the separator 4 is 2.0 hours, the solution is layered, the upper part is the extractant phase, and the lower part is the brine phase. The extraction phase is drawn from the upper part of the separator, and the raffinate phase is drawn from the lower part of the separator 4 and flows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com