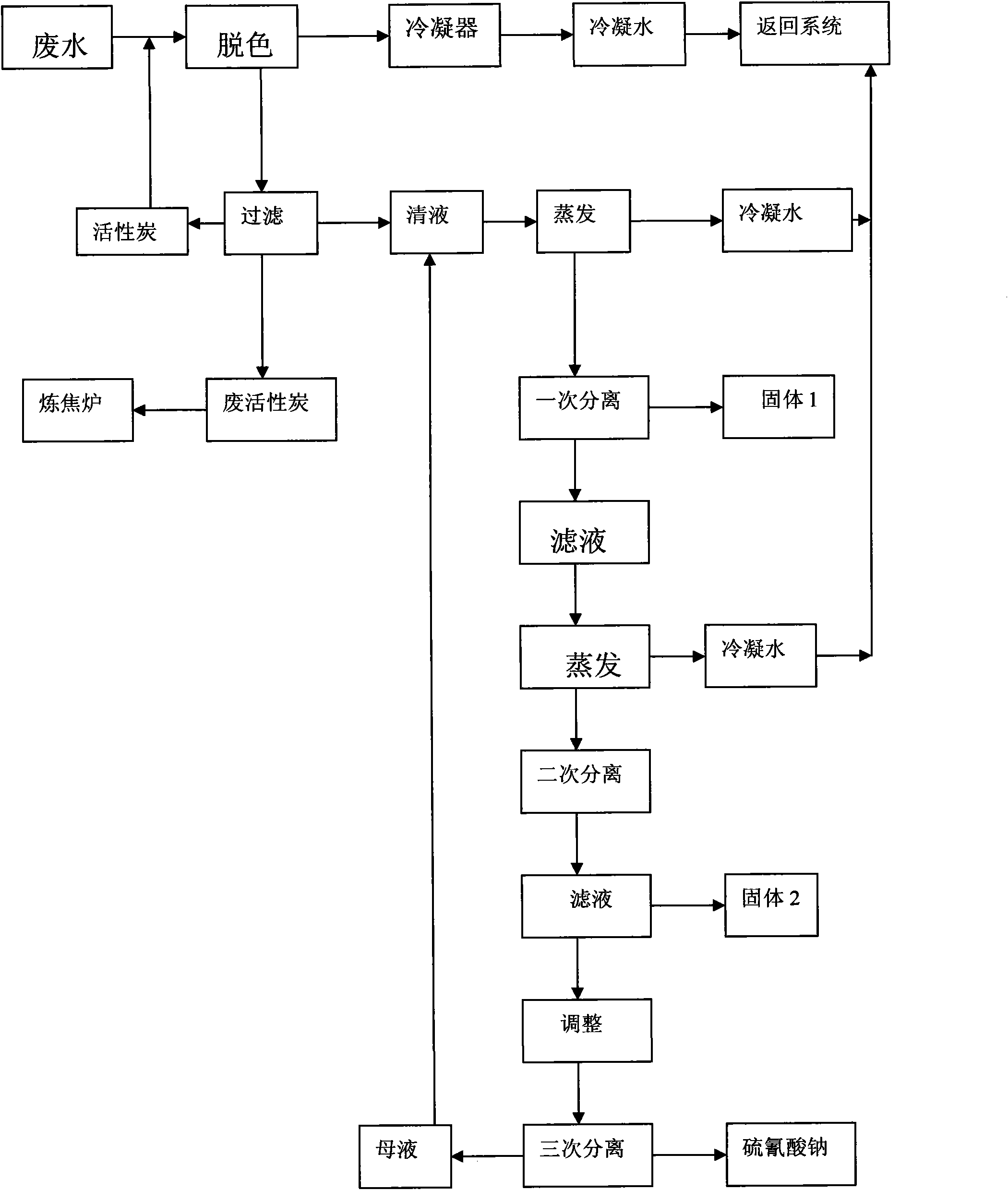

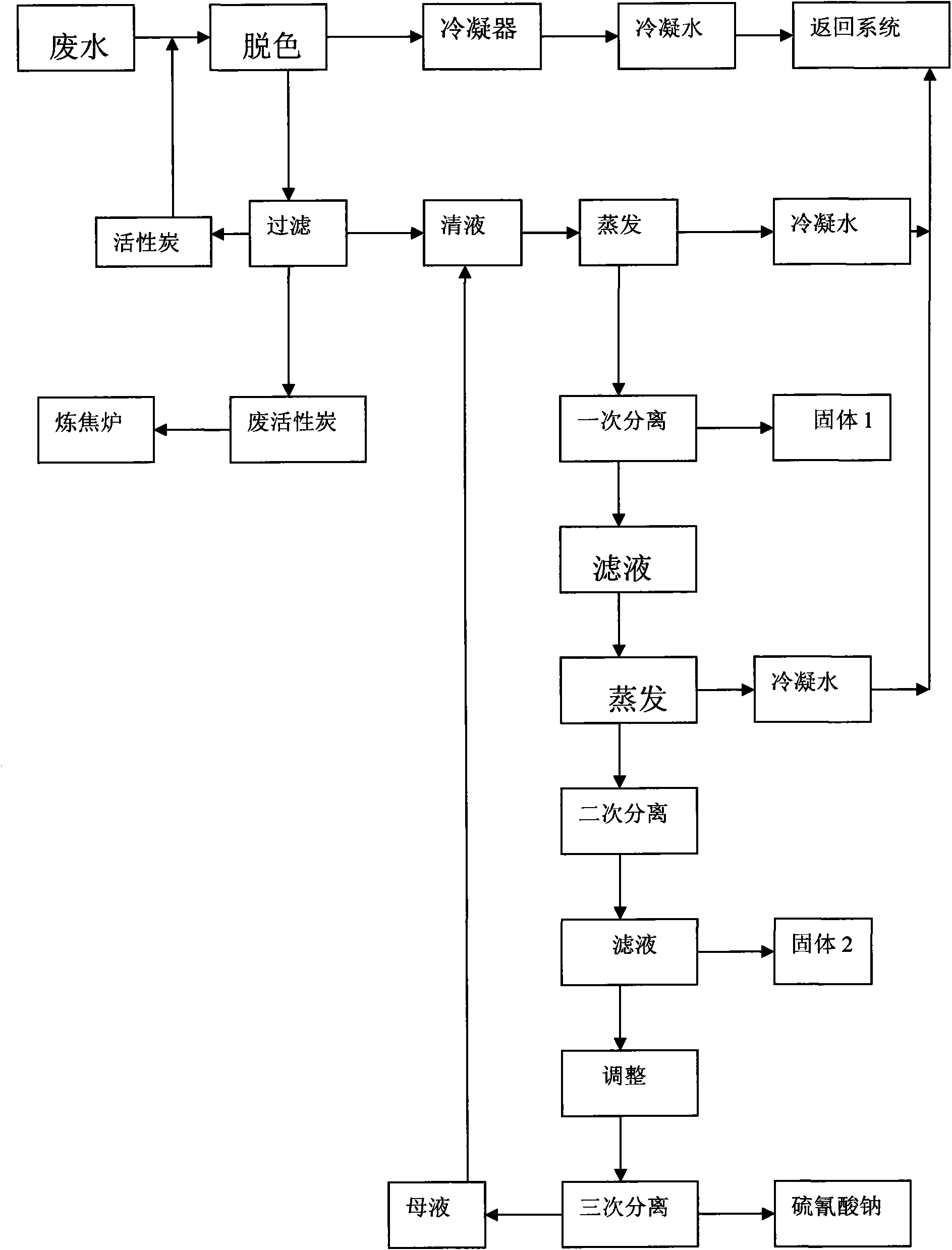

Method for recovering sodium sulfocyanate from desulfurized and decyanated wastewater of coke-oven gas

A technology for desulfurization, decyanation, and sodium thiocyanate, applied in thiocyanic acid and other directions, can solve the problems of unreasonable economic benefits, increased recycling burden, and high equipment requirements, and achieve the effects of low cost, novel technology, and elimination of environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] Step 1: Evaporation and liquid-solid separation 1

[0017] 3002 grams of decolorizing solution (component: NaCNS: 4.92%, Na 2 S 2 o 3 : 5.56%, Na 2 SO 4 : 1.66%, Na 2 CO 3 : 1.60%, H 2 O: 82.26%) add 750 grams of circulating mother liquor that returns, concentrate (can decompress) and remove 2070ml of water, then separate at 60°C-80°C to obtain the first filtrate 1242ml, solid (1) 156.2g (component: NaCNS: 4.12 %, Na 2 S 2 o 3 : 5.08%, Na 2 SO 4 : 41.89%, Na 2 CO 3 : 45.71%, H 2 O: 3.2%).

[0018] Step 2: Evaporation and liquid-solid separation 2

[0019] The first separated filtrate 1242ml evaporated to remove water again to obtain concentrated slurry, and carried out secondary separation at 60°C-90°C to obtain the second filtrate 705ml, solid (2) 248.5 grams (component: NaCNS: 15.74%, NaCNS: 15.74%, Na 2 S 2 o 3 : 74.12%, Na 2 SO 4 : 3.33%, Na 2 CO 3 : 2.71%, H 2 O: 4.10%).

[0020] The third step: crystallization and separation of NaCNS

[0...

example 2

[0023] Step 1: Evaporation and liquid-solid separation 1

[0024] 3815 grams of decolorizing solution (component: NaCNS: 5.56%, Na 2 S 2 o 3 : 7.72%, Na 2 SO 4 : 1.84%, Na 2 CO 3 : 1.78%, H 2 (O: 83.10%) adds 670 grams of circulating mother liquor that returns, concentrates (can decompress) and removes 2516ml of water, separates the first filtrate 1360ml, solid (1) 135.2 grams (component: NaCNS: 4.66%, Na 2 S 2 o 3 : 6.50%, Na 2 SO 4 : 43.12%, Na 2 CO 3 : 42.92%, H 2 O: 2.8%).

[0025] Step 2: Evaporation and liquid-solid separation 2

[0026]The first separated filtrate 1360ml is evaporated to remove water to obtain concentrated slurry again, carries out secondary separation at 60 ℃-90 ℃, obtains the second filtrate 787ml, solid (2) 382 grams (component: NaCNS: 13.96%, NaCNS: 13.96%, Na 2 S 2 o 3 : 76.38%, Na 2 SO 4 : 2.88%, Na 2 CO 3 : 2.24%, H 2 O: 4.54%).

[0027] The third step: crystallization and separation of NaCNS

[0028] After the filtrate 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com