Zero sludge and resource handling arrangement and recovery method of heavy metal waste water

A treatment device and recovery method technology, applied in water/sludge/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the burden, cannot effectively solve environmental pollution, and cannot improve copper-containing sludge recovery rate etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

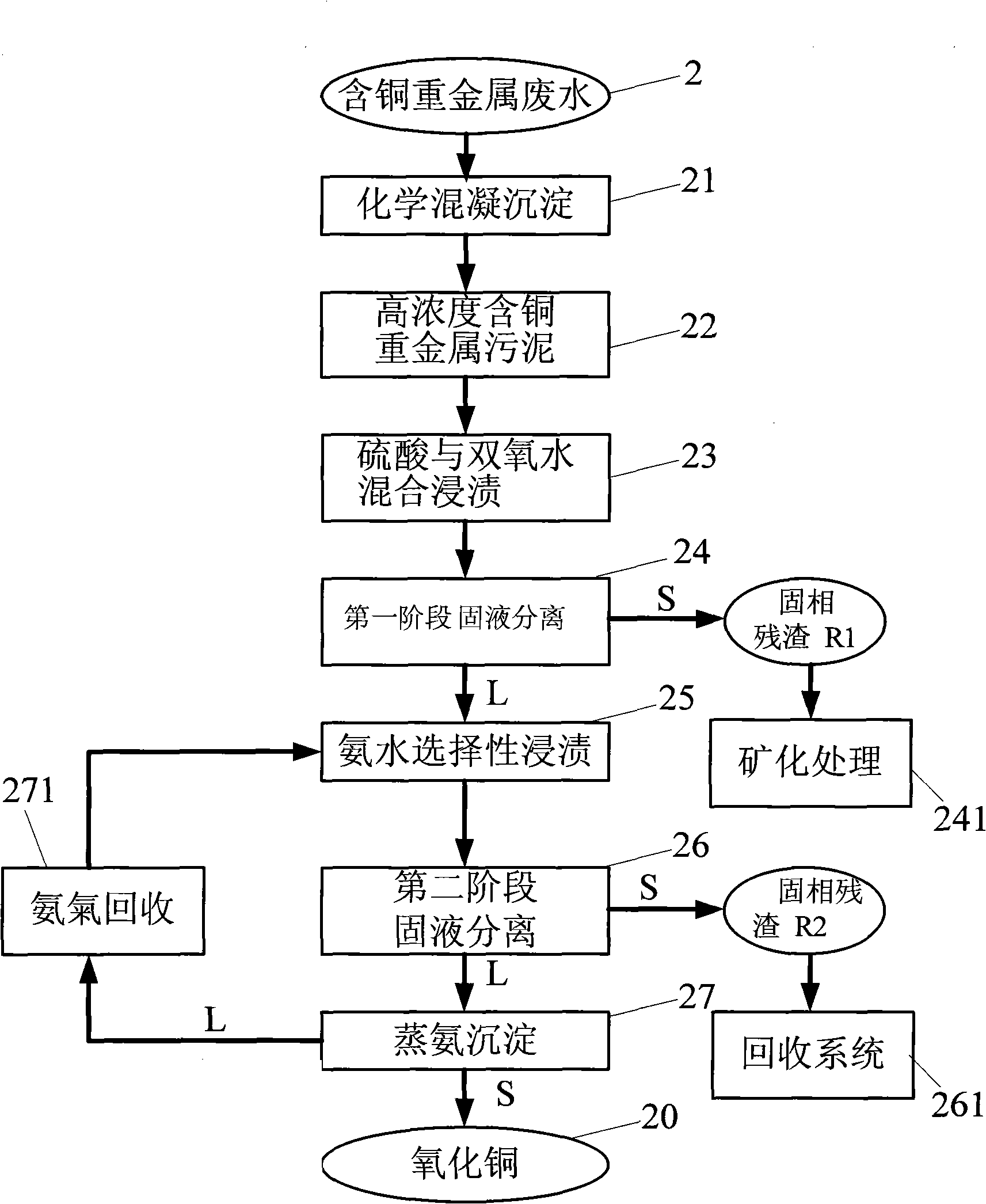

[0042] See first figure 2, Is the flow chart of the present invention. After the copper-containing heavy metal wastewater 2 is treated by chemical coagulation precipitation 21, the copper-containing heavy metal sludge 22 with high concentration of copper ions is concentrated, and it is impregnated with a mixture of sulfuric acid and hydrogen peroxide 23 Afterwards, an impregnation solution with a high concentration of copper ions of 18-40% can be obtained, and then the first stage of solid-liquid separation 24 can be carried out. The solid-phase residue R1 can be stabilized by mineralization treatment 241, or smelted to recover iron or Aluminum, etc. achieve the purpose of recycling. In addition, after the first stage of solid-liquid separation 24, the liquid phase reuses ammonia water as selective impregnatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com