One-pot method for simultaneously preparing carbon quantum dots and porous carbon

A technology of carbon quantum dots and porous carbon, which is applied in the field of simultaneous preparation of carbon quantum dots and porous carbon in a one-pot method, can solve problems such as patent publications that have not yet been found, and achieve high-efficiency and high-value utilization, abundant resources, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

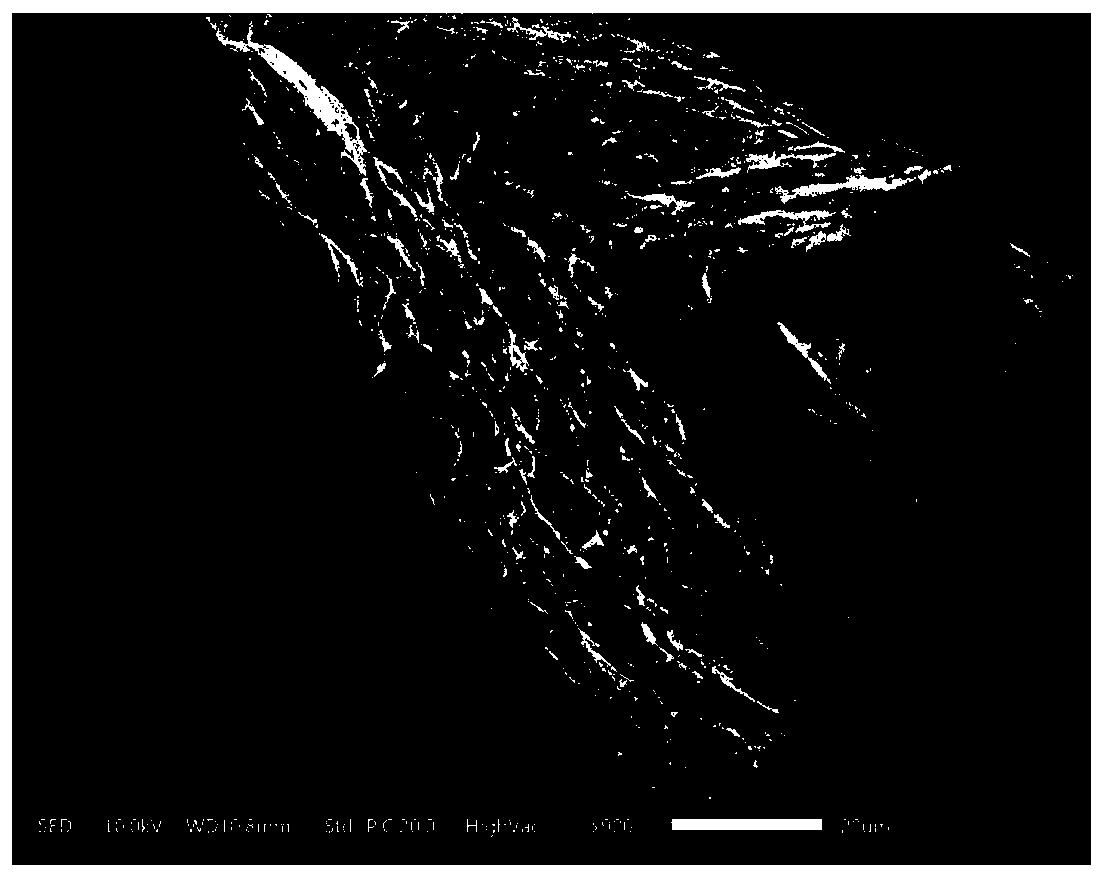

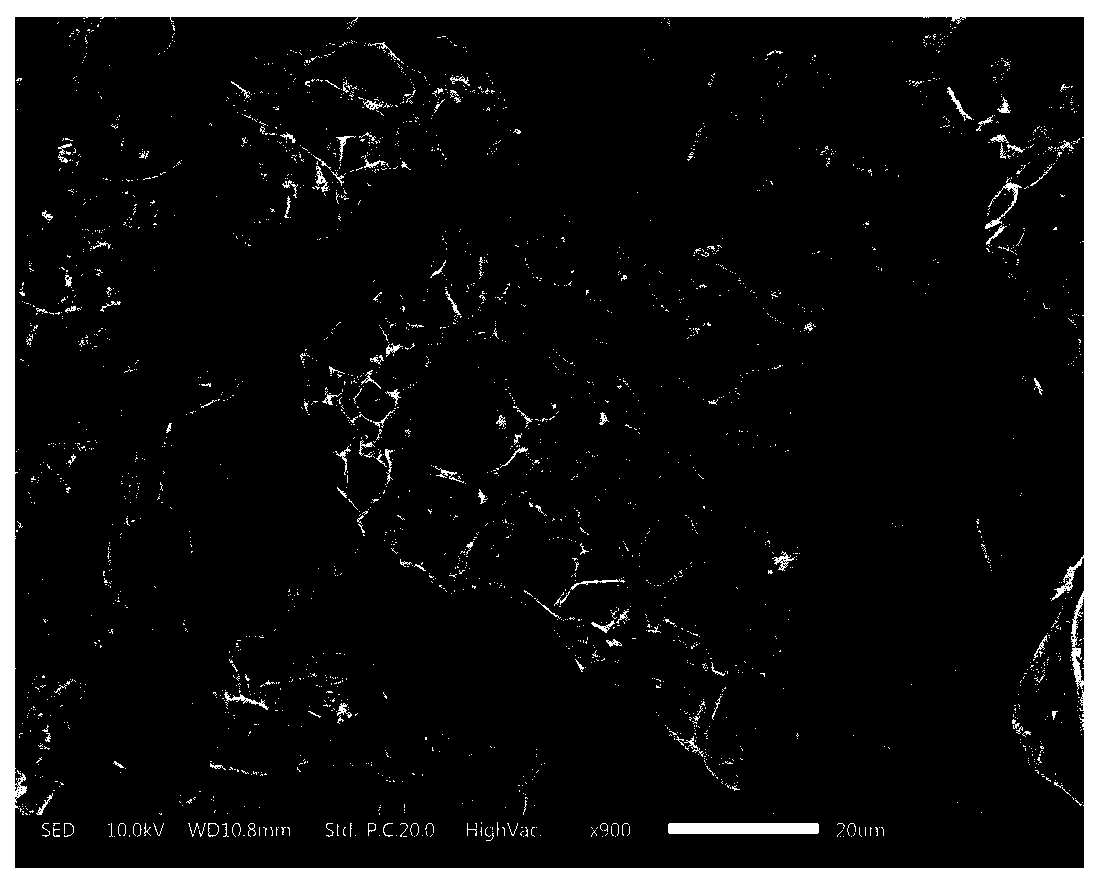

Image

Examples

Embodiment 1

[0032] A method for simultaneously preparing carbon quantum dots and porous carbon in a one-pot method, the steps are as follows:

[0033] (1) Weigh 24g of corn cob lignin, disperse it in 120mL of deionized water, stir at 50°C for 10min, then transfer it to a high-temperature and high-pressure reactor, heat it to 180°C, keep it warm for 5h, the pressure is 1.1MPa, and the stirring speed is 200°C rev / min, the reaction ends, and the heating is stopped.

[0034] (2) Take the mixed liquid in step (1) out of the high-temperature and high-pressure reaction kettle, and filter it through a 0.22 μm circular filter membrane to obtain liquid and solid residues respectively, and dry the obtained solid residues at 105°C to constant weight ,spare. The resulting liquid was dialyzed with a 3500 Dalton semi-permeable membrane for 2 days (change the water once every 6 hours), and the carbon quantum dot solid doped with nitrogen was obtained by rotary evaporation and lyophilization.

[0035] (...

Embodiment 2

[0041] A method for simultaneously preparing carbon quantum dots and porous carbon in a one-pot method, the steps are as follows:

[0042] (1) Weigh 24g of corn cob lignin, add 12g of phosphoric acid, disperse in 120mL of deionized water, and stir at 50°C for 10min. Then transfer to a high-temperature and high-pressure reactor, heat to 180° C., keep warm for 5 hours, the pressure is 1.2 MPa, the stirring speed is 200 rpm, the reaction is over, and the heating is stopped.

[0043] (2) Take the mixed liquid in step (1) out of the high-temperature and high-pressure reaction kettle, filter it with a filter membrane of 0.22 μm, and obtain liquid and solid residues respectively. The obtained solid residues are transferred to a glass container and dried at 105°C To constant weight, set aside. The resulting liquid was dialyzed in deionized water for 2 days with a semipermeable membrane with a molecular weight cut-off of 3500D (change the water every 6 hours), and then obtained carbon...

Embodiment 3

[0050] A method for simultaneously preparing carbon quantum dots and porous carbon in a one-pot method, the steps are as follows:

[0051] (1) Weigh 24g of corncob lignin, add 12g of phosphoric acid, disperse in 120mL of deionized water, stir at 50°C for 10min, then transfer to a high temperature and high pressure reactor, heat to 180°C, hold for 5h, and the pressure is 1.2MPa , the stirring speed is 200 rpm, the reaction is over, and the heating is stopped.

[0052] (2) Take the mixed liquid in step (1) out of the high-temperature and high-pressure reaction kettle, and filter it with a filter membrane of 0.22 μm to obtain liquid and solid residues respectively. The obtained solid residues are transferred to a glass container and baked at 105°C Dry to constant weight and set aside. The resulting liquid was dialyzed in deionized water for 2 days with a semipermeable membrane with a molecular weight cut-off of 3500D (change the water every 6 hours), and then obtained carbon qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com