Method for directly preparing metallic lead by utilizing galena

A technology for galena and metallic lead is applied in the field of directly preparing metallic lead by using galena, which can solve the problems of high energy consumption, environmental pollution and the like, and achieve the effects of low energy consumption, high efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

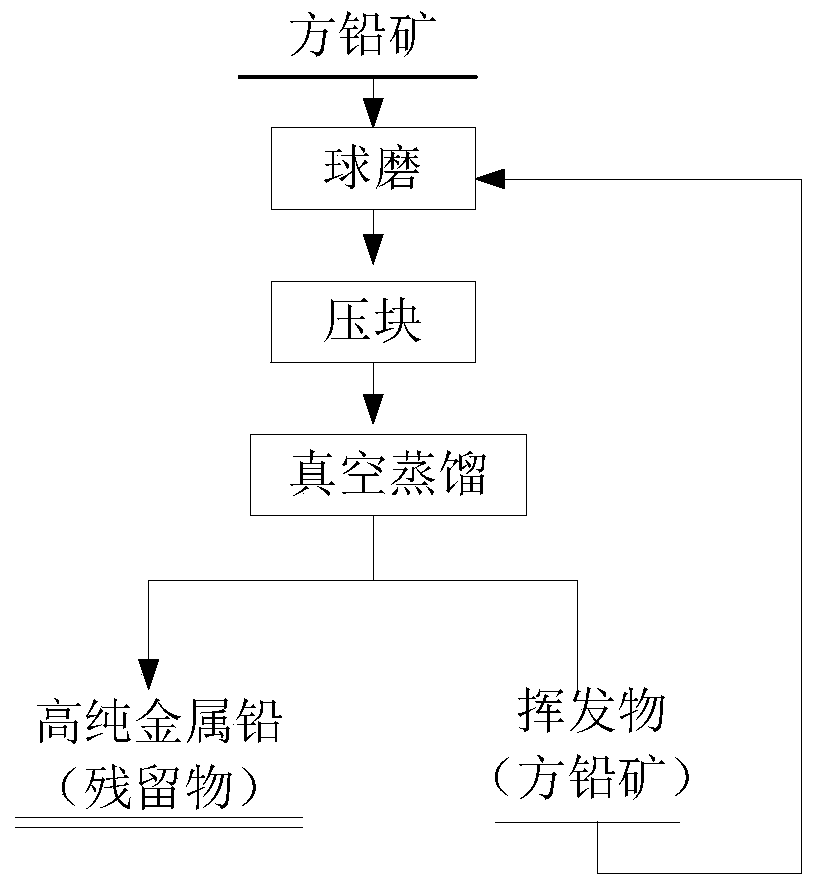

[0032] Such as figure 1 Shown, this galena prepares the method for metallic lead, and its specific steps are as follows: first utilize ball mill ball milling 50g galena raw material (containing PbS 98.12wt%) and press into cylindrical block (diameter is 20mm, height is 30mm) , under the condition that the residual pressure of the system in the vacuum furnace is 10Pa, the cylindrical briquette is raised to 1100°C at a rate of 8°C / min, and the distillation is kept for 45 minutes. After the heat preservation is completed, stop heating and let the vacuum furnace cool naturally. The temperature is lowered below 50°C to obtain high-purity metallic lead residues containing 99.99% by weight of metallic lead and undecomposed galena volatiles, and the volatiles are continued to be ball-milled with raw materials to form blocks to continue vacuum distillation, and the above-mentioned distillation process is repeated .

Embodiment 2

[0034] Such as figure 1 Shown, this galena prepares the method for metallic lead, and its specific steps are as follows: first 50g galena raw material (containing PbS 97.96wt%) utilizes the ball mill to be pressed into cylindrical block (diameter is 20mm, and height is 30mm) , under the condition that the residual pressure of the system in the vacuum furnace is 50Pa, the cylindrical briquette is raised to 1200°C at a rate of 5°C / min, and the distillation is kept for 40 minutes. After the heat preservation is completed, stop heating and let the vacuum furnace cool naturally. The temperature is lowered below 50°C to obtain high-purity metallic lead residues containing 99.99% by weight of metallic lead and undecomposed galena volatiles, and the volatiles are continued to be ball-milled with raw materials to form blocks to continue vacuum distillation, and the above-mentioned distillation process is repeated .

Embodiment 3

[0036] Such as figure 1 As shown, the method for preparing metallic lead from this galena, its specific steps are as follows: first, 50g of galena raw material (containing PbS 97.12wt%) is pressed into a cylindrical block (with a diameter of 20mm and a height of 30mm) after being ball milled by a ball mill , under the condition that the residual pressure of the system in the vacuum furnace is 100Pa, the cylindrical briquette is raised to 1400°C at a rate of 10°C / min, and the distillation is kept for 50 minutes. The temperature is lowered below 50°C to obtain high-purity metallic lead residues containing 99.99% by weight of metallic lead and undecomposed galena volatiles, and the volatiles are continued to be ball-milled with raw materials to form blocks to continue vacuum distillation, and the above-mentioned distillation process is repeated .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com