Method for preparing nanometer molybdenum disulfide by aid of microemulsion system

A nano-molybdenum disulfide and microemulsion technology, which is applied in the direction of molybdenum sulfide and nanotechnology, can solve the problems that have not been seen in the preparation of nano-molybdenum disulfide, and achieve the effect of uniform particles, controllable particle size, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

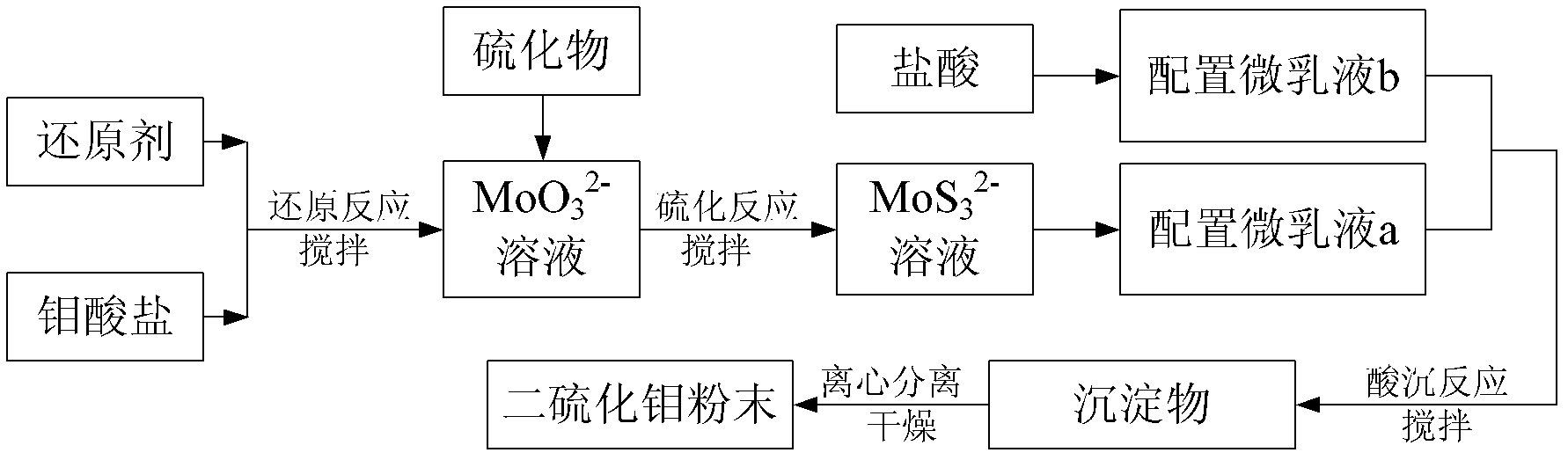

[0019] A kind of method adopting microemulsion system to prepare nano molybdenum disulfide comprises the steps:

[0020] Step 1, adding oxalic acid to the sodium molybdate solution with a concentration of 0.05mol / L to reduce it to tetravalent sodium molybdate, the ratio of sodium molybdate to oxalic acid is 1:1, and the reaction temperature is 65°C. The reaction time is 75 minutes;

[0021] Step 2, adding sodium sulfide to the solution obtained in step 1 to make it vulcanized, the ratio of the amount of sodium sulfide to sodium molybdate in step 1 is 3: 1, the reaction temperature is 75 ° C, and the reaction time is 90 min;

[0022] Step 3, use TritonX100, isoamyl alcohol, n-heptane, the solution obtained in the above step 2 and secondary deionized water to configure microemulsion a; use TritonX100, isoamyl alcohol, n-heptane, 1mol / L hydrochloric acid and secondary Prepare microemulsion b with deionized water, then add all microemulsion b into microemulsion a, carry out acid ...

Embodiment 2

[0026] A kind of method adopting microemulsion system to prepare nano molybdenum disulfide comprises the steps:

[0027] Step 1, add hydroxylamine hydrochloride in the potassium molybdate solution that concentration is 0.03mol / L and reduce it to tetravalent potassium molybdate, the ratio of the amount of potassium molybdate and hydroxylamine hydrochloride substance is 1: 1.3, and the reaction temperature is 75 ℃, reaction time 85min;

[0028] Step 2, adding potassium sulfide to the solution obtained in step 1 to make it vulcanized, the ratio of potassium sulfide to the amount of potassium molybdate in step 1 is 4: 1, the reaction temperature is 85 ° C, and the reaction time is 100 min;

[0029] Step 3, use TritonX100, isoamyl alcohol, n-heptane, the solution obtained in the above step 2 and secondary deionized water to configure microemulsion a; use TritonX100, isoamyl alcohol, n-heptane, 1mol / L hydrochloric acid and secondary Prepare microemulsion b with deionized water, the...

Embodiment 3

[0033] A kind of method adopting microemulsion system to prepare nano molybdenum disulfide comprises the steps:

[0034] Step 1, in the ammonium molybdate solution that concentration is 0.04mol / L, add hydroxylamine hydrochloride and reduce it to tetravalent ammonium molybdate, the ratio of the amount of ammonium molybdate and hydroxylamine hydrochloride substance is 1: 1.2, and the reaction temperature is 70 ℃, reaction time 80min;

[0035] Step 2, adding sodium sulfide to the solution obtained in step 1 to make it vulcanized, the ratio of sodium sulfide to the amount of ammonium molybdate in step 1 is 3: 1, the reaction temperature is 80 ° C, and the reaction time is 95 min;

[0036]Step 3, use TritonX100, isoamyl alcohol, n-heptane, the solution obtained in the above step 2 and secondary deionized water to configure microemulsion a; use TritonX100, isoamyl alcohol, n-heptane, 1mol / L hydrochloric acid and secondary Prepare microemulsion b with deionized water, then add all m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com