Apparatus for quickly mixing chemical melt and solid powder

A mixing device and melt technology, applied in mixers, fluid mixers, transportation and packaging, etc., can solve the problems of oversized suspended solids in slurry and long mixing time of raw materials in kettle structure, etc. Achieve the effect of shortening the mixing time and avoiding the agglomeration of powder materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

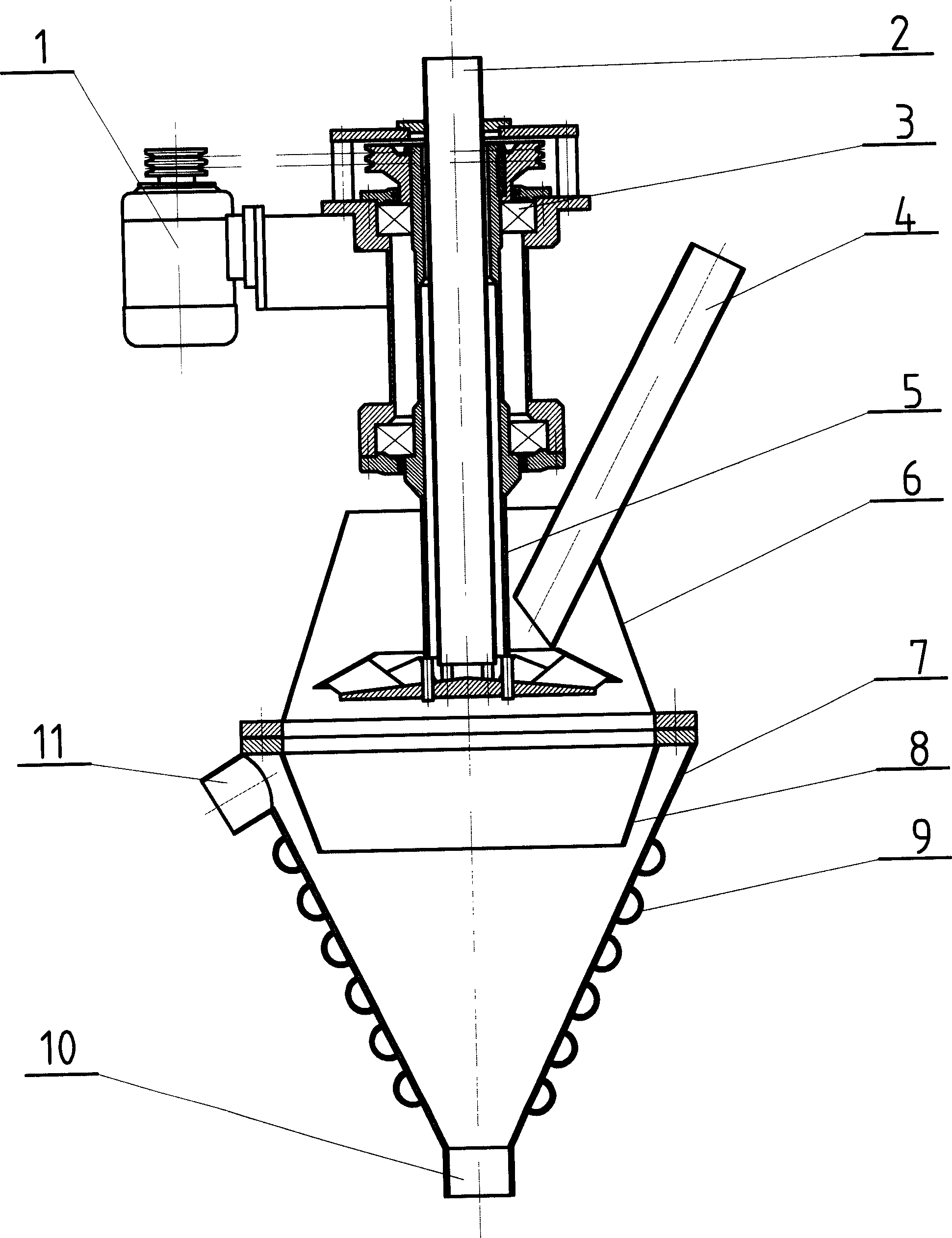

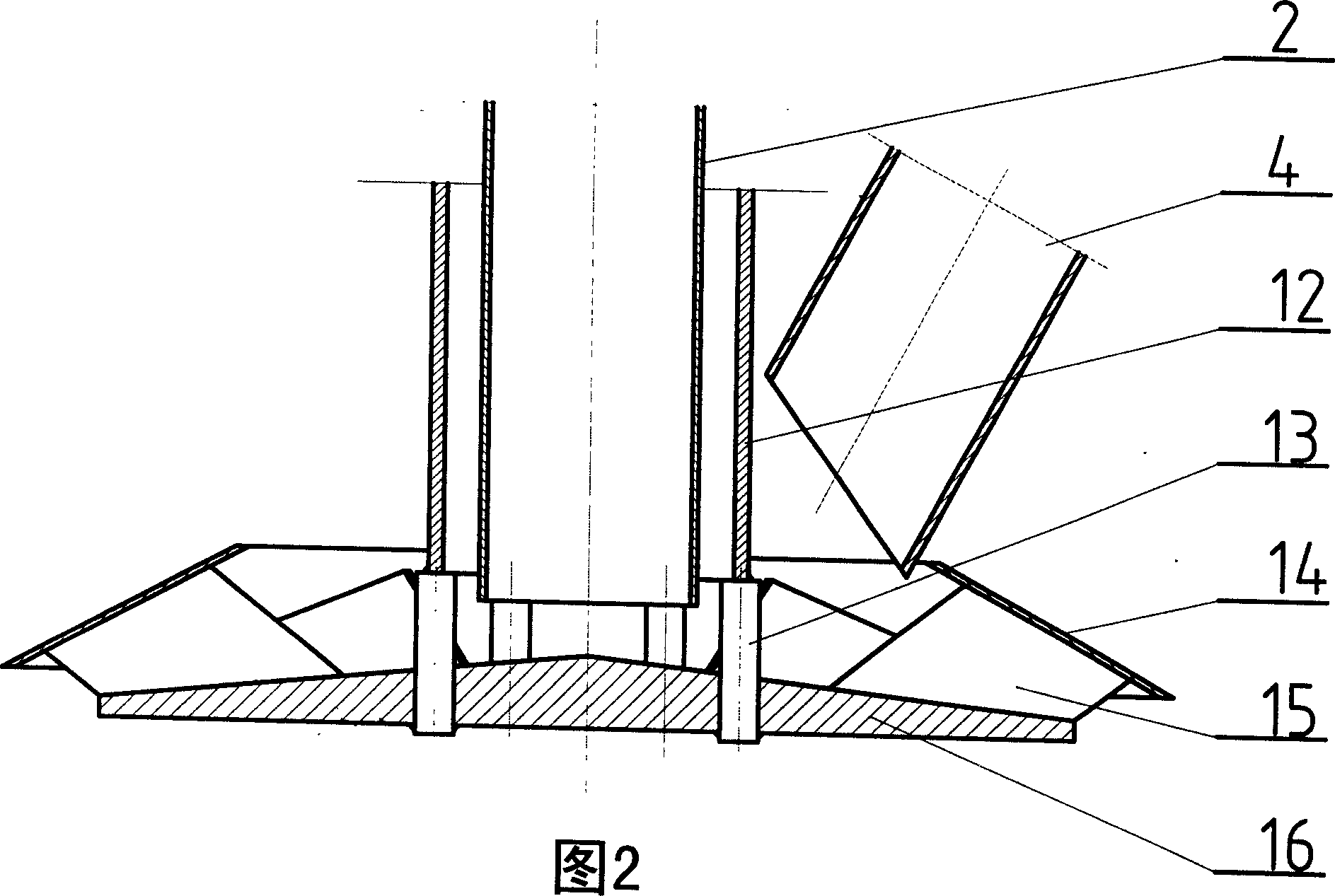

[0018] Such as figure 1 , shown in Fig. 2, chemical melt and solid powder fast mixing device of the present invention, comprise mixing tank, liquid feed pipe 2, powder feed pipe 4, discharge port 10 and can pass motor 1 and transmission mechanism 3 Driven shaft 12, the mixing tank adopts the upper mixing cone 6 and the lower mixing cone 7 fixedly connected together, the top of the lower mixing cone 7 is also provided with an inner mixing cone 8, the upper mixing cone 6, the lower mixing cone Platform 7 and inner mixing cone 8 are both concentric truncated cones rolled by metal plates. Upper mixing cone 6 is placed with a small top and a large bottom, and the lower mixing cone 7 and inner mixing cone 8 are placed with a large top and a small bottom. The discharge port 10 is arranged at the bottom of the lower mixing cone 7, and there is a mixing impeller 5 in the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com