Heating or cooling containers

A self-heating and self-refrigerating technology, used in food heating containers, containers, household refrigeration devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

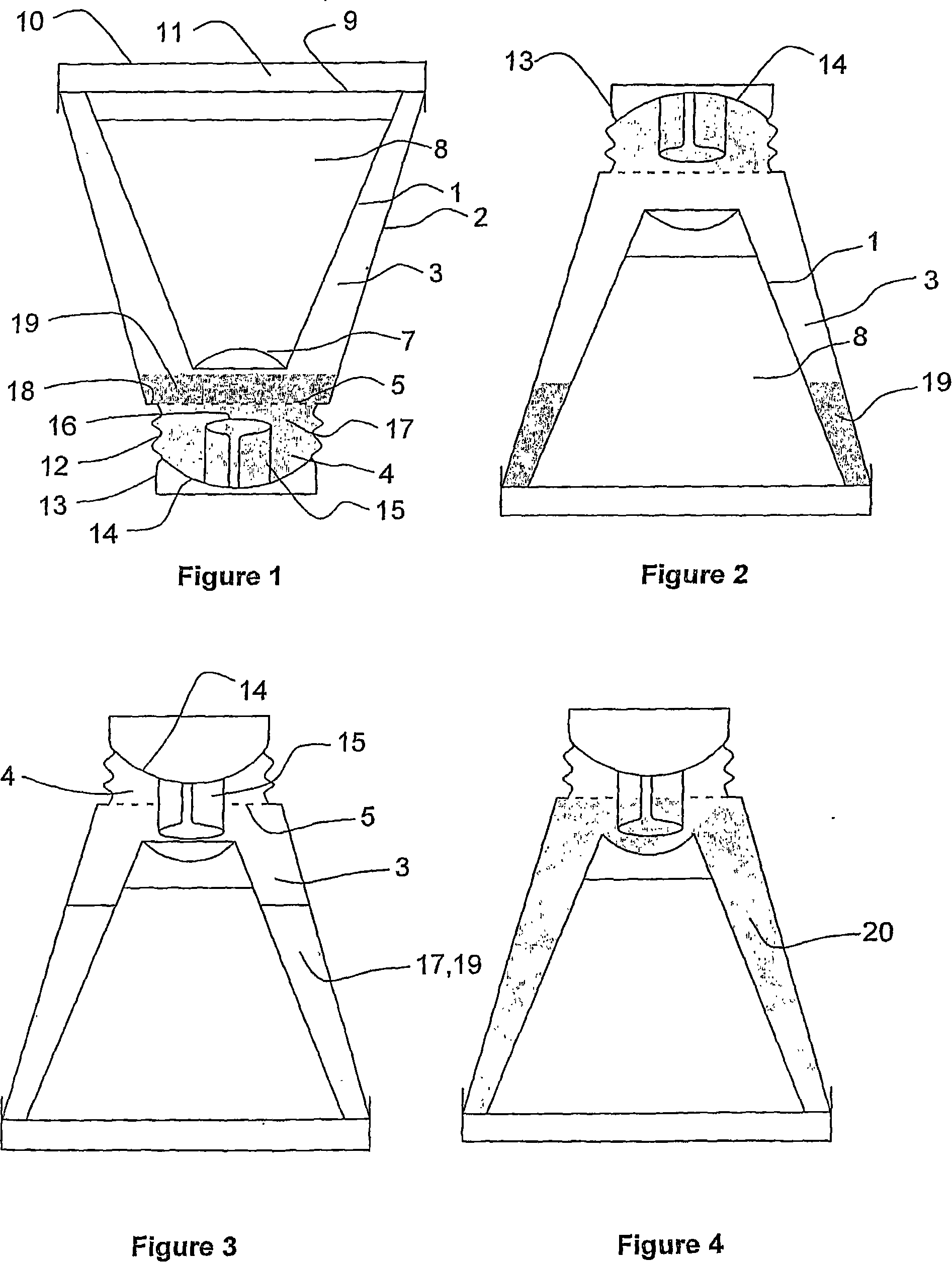

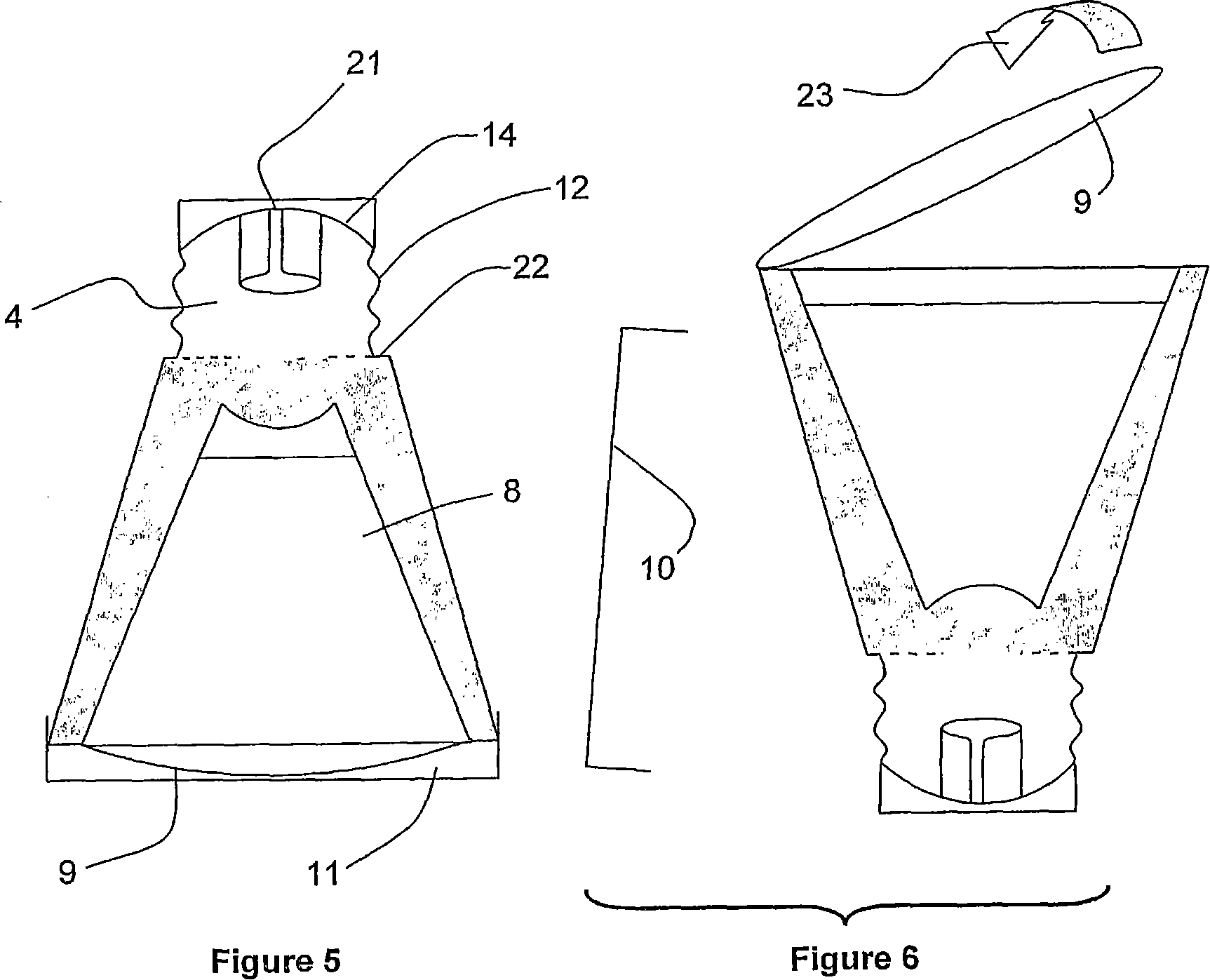

[0020]Figure 1 shows the container as it will be sold, before use. The container comprises an inner container 1 and an outer container 2 defining a reaction chamber between them. The reaction chamber is divided into a first chamber 3 and a second chamber 4 by a rupturable frangible partition 5, the barrier layer 5 being shown in dotted line in FIG. 1 . The inner container 1 is made of a rigid thermally conductive material, such as aluminium. The outer container 2 is made of a rigid thermally insulating material, such as a rigid thermoplastic, the rigidity of which can be increased by providing closely spaced longitudinal ribs (ribs) (not shown) on the outer surface, which increase the rigidity of the outer container 2 , and also provide beneficial thermal barrier properties, such that the hot container is picked up and held in the user's hand without burning the user's fingers. The inner and outer containers are joined together at edges 6 around their outer edges. The base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com