Liquid ammonia vaporization method

A liquid ammonia and vaporizer technology, which is applied in the method of container discharge, gas/liquid distribution and storage, and equipment discharged from pressure vessels, etc., can solve the problem of reduced heat exchange efficiency, unstable ammonia pressure transportation, and poor operation safety. and other problems, to achieve the effect of maintaining continuous and stable discharge, making full use of heat exchange efficiency, and avoiding the increase of heat exchange thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

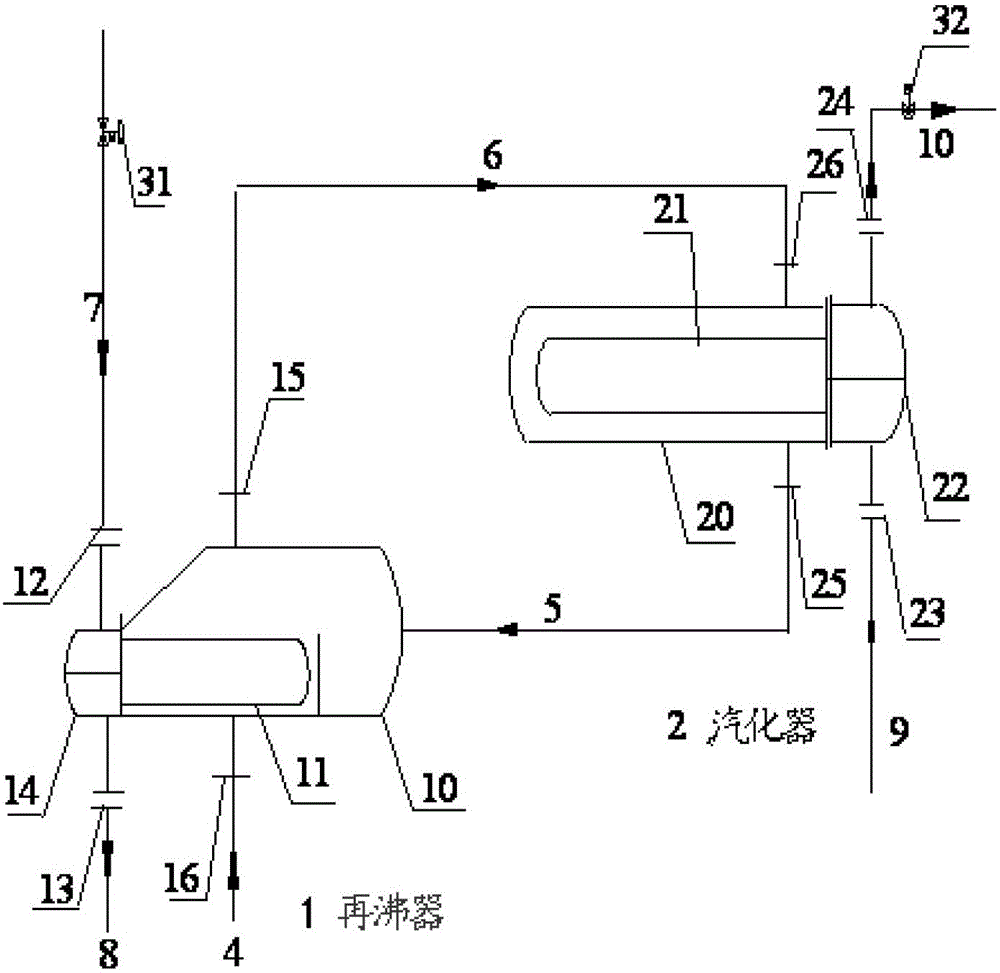

[0026] 2.0MPa steam enters the reboiler tube side through the steam port at 643kg / h, heats the dimethoxymethane in the reboiler after heat exchange through the heat exchange tube, and the steam condenses to form water at 106°C and flows out at 643kg / h for reboil Dimethoxymethane is heated and vaporized at 536kg / h, heated to a temperature of 65°C, and becomes dimethoxymethane gas after heat exchange, and rises into the vaporizer, and the dimethoxymethane gas heats the tube side of the vaporizer , exchange heat with ammonia in the tube side of the evaporator, condense into a heat medium liquid, and then flow into the reboiler;

[0027] The liquid ammonia from the outside enters the tube side of the vaporizer at 1360kg / h, receives the heat provided by the heat medium gas and vaporizes into gaseous ammonia at a temperature of 52°C and a pressure of 1.0MPa. The gaseous ammonia is discharged through the outlet of the tube side of the vaporizer at a flow rate of 1360kg / h. The regulat...

Embodiment 2

[0029] 2.5MPa steam enters the reboiler tube side through the steam port at 598kg / h, heats the dimethoxymethane in the reboiler after heat exchange through the heat exchange tube, and the steam condenses to form water at 126°C and flows out at 598kg / h for reboiler Dimethoxymethane is heated and vaporized at 633kg / h, and heated to a temperature of 121°C. After heat exchange, it becomes dimethoxymethane gas and rises into the vaporizer, and the dimethoxymethane gas heats the tube side of the vaporizer , after heat exchange with ammonia in the tube side of the evaporator, it condenses into a heat medium liquid, and then flows into the reboiler, wherein the reboiler communicates with the evaporator;

[0030] The liquid ammonia from the outside enters the vaporizer tube at 1360kg / h, receives the heat provided by the heat medium gas, and vaporizes into gaseous ammonia at a temperature of 105°C and a pressure of 2.0MPa. The regulating valve directly controls the flow and pressure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com