Stable continuous discharging device of high temperature bulk material heat exchanger

A technology for heat exchangers and bulk materials, applied in the direction of heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve problems such as poor fluidity, easy arching, blocking high-temperature bulk materials, etc., to achieve long life and high performance The effect of stability and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0021] In view of the fact that high-temperature solid bulk materials are easy to accumulate and block at the discharge pipe and the necking of the discharge hopper, which affects the continuous and stable discharge of solid bulk materials, and then affects the waste heat recovery of solid bulk materials, a method for stabilizing high-temperature bulk materials is proposed. Method and device for continuous discharge.

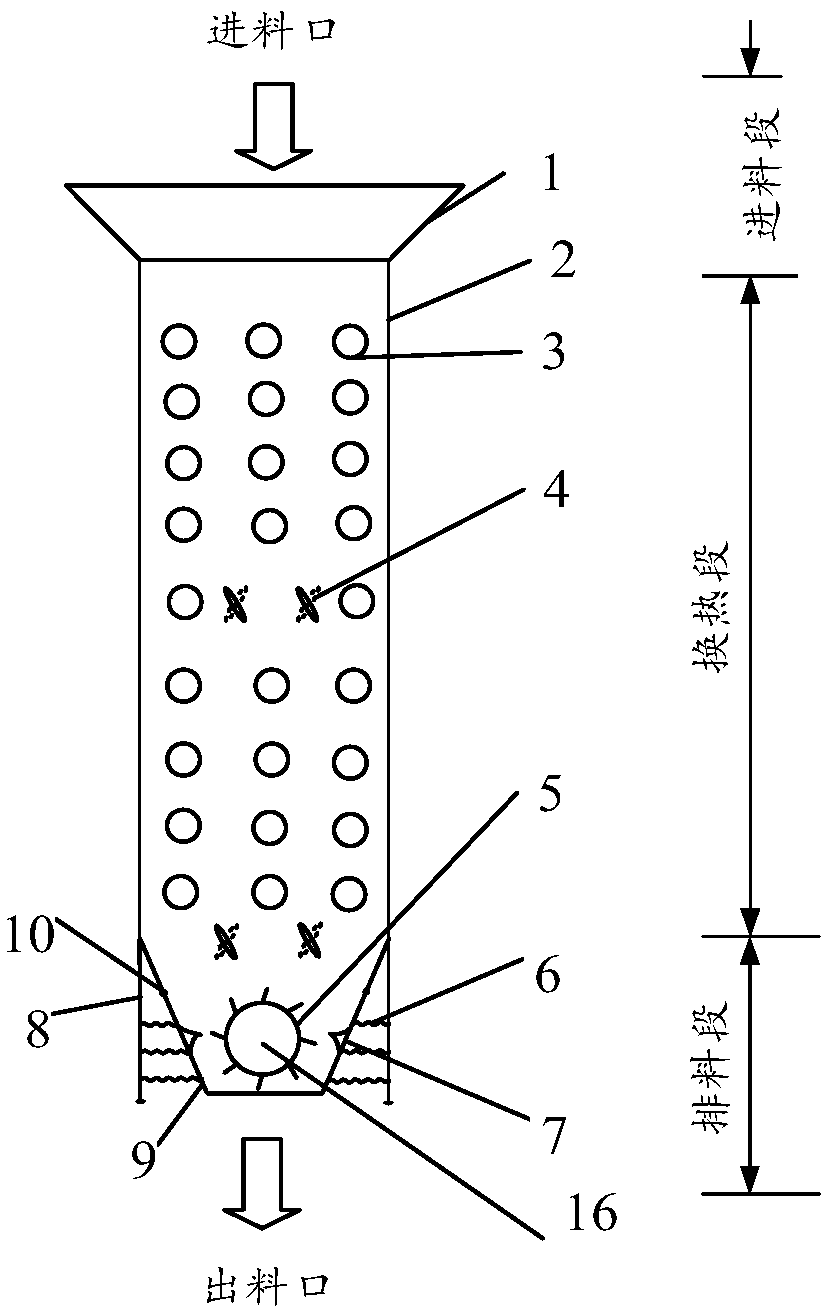

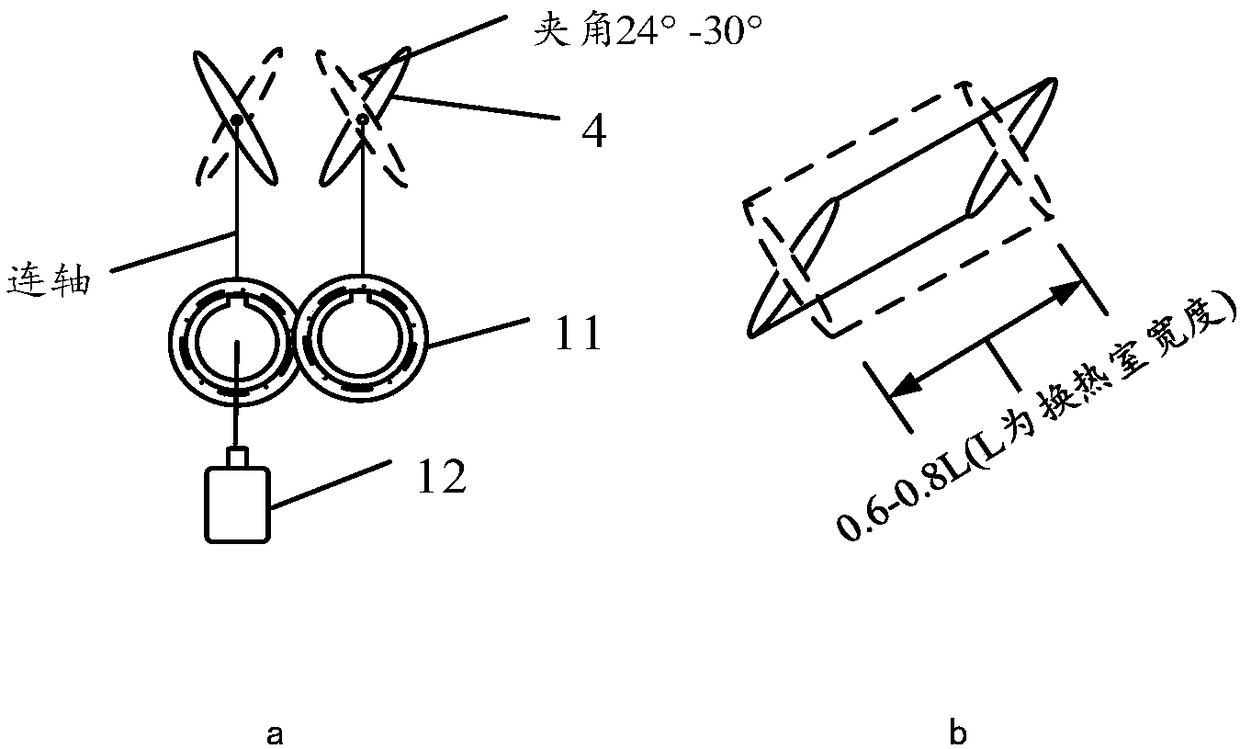

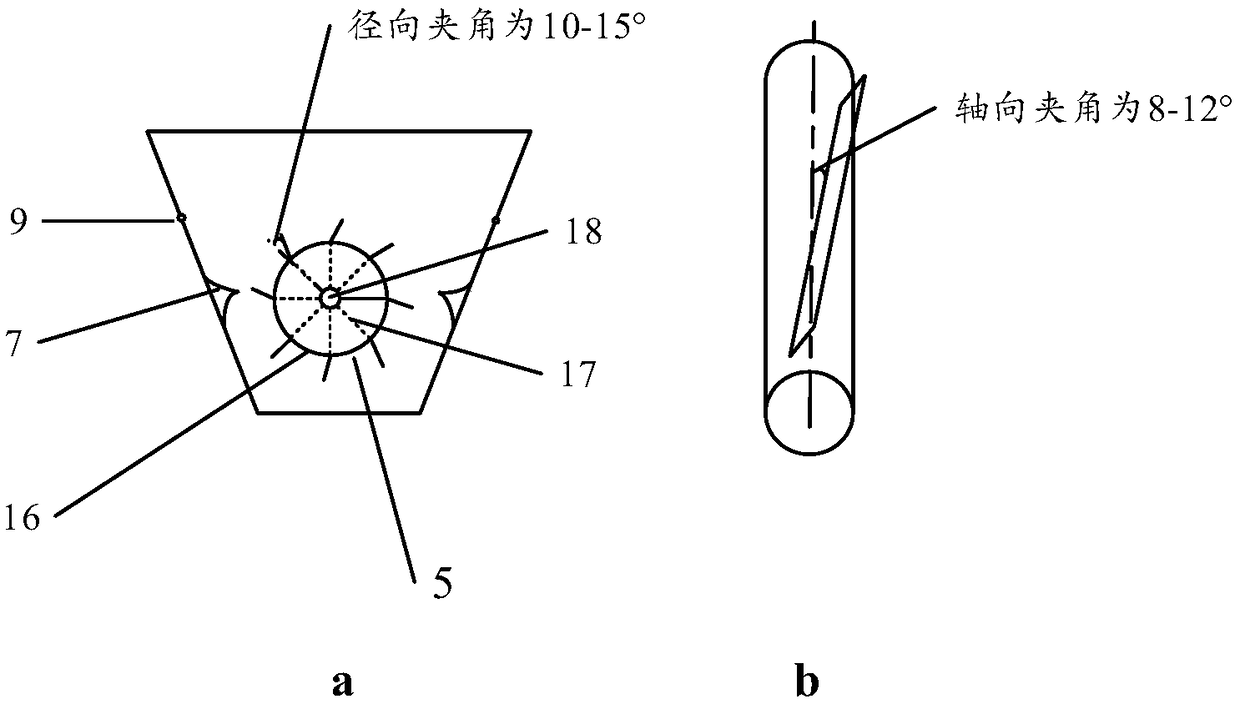

[0022] The overall structure of the bulk material stable and continuous discharge device consists of a feed hopper (1), a heat exchanger (2), a heat exchange pipe (3), a "shuttle" type spoiler (4), an improved "star" Type discharge device (5), movable discharge hopper (6), block (7), side wall (8), movable plate (9), hinge (10), gear (11),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com