Capacitive electrizer

A generator and capacitive technology, applied in the direction of induction generators, etc., can solve problems such as easy interruption of current, obstacles to the convenience of power generation operation, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

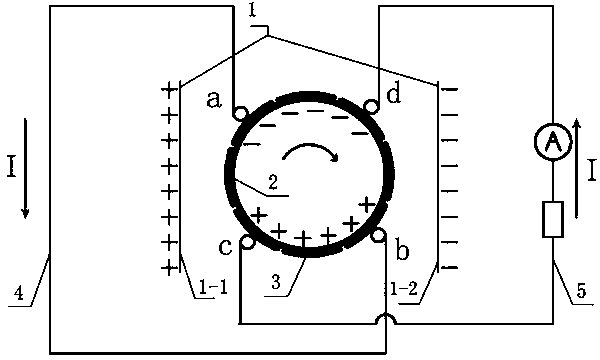

[0021] The present invention will be further described in detail below in conjunction with the drawings, such as figure 1 As shown, the capacitor motor includes: an electrode plate (1), a roller (2) and an external circuit, characterized in that the roller is located between the electrode plates, the roller can roll around the axis of the roller, and the roller There is a non-connected metal sheet (3) on the periphery, and the external circuit is connected with the metal sheet; during the rolling process of the roller, the negative electrons move from a metal sheet with a lower potential to a higher potential connected to it under the action of the electric field force On the metal sheet, the two metal sheets are then separated. Driven by external force, when the metal sheet with negative electrons moves to a lower potential position, at the same time, the metal sheet corresponding to and separated and showing positive electric characteristics When moving to a higher potential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com