Biomass material lock and working method

A biomass and material lock technology, applied in the field of biomass material lock, can solve problems such as fluctuations in the working conditions of biomass incinerators or biomass gasifiers, incineration feeding systems, explosions, etc., to achieve comprehensive utilization of energy and applicable materials Wide range of effects and reliable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

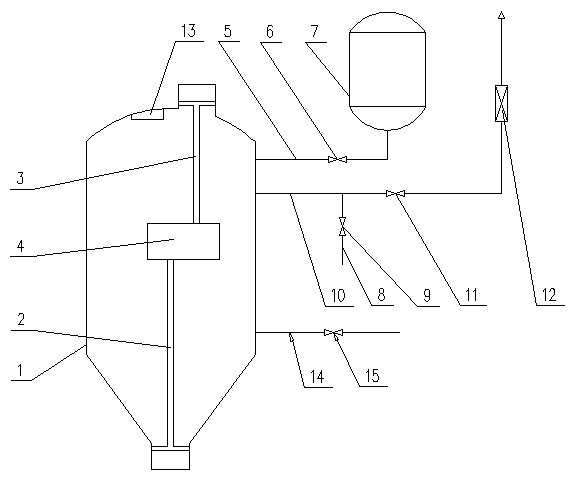

[0021] A biomass material lock, which consists of: a housing 1, a discharge valve 2 is installed inside the housing, the discharge valve is connected to the feed valve 3 through a transmission mechanism 4, and the housings are respectively It is connected with the primary pressure relief pipeline 5, the secondary pressure relief pipeline 10, and the air seal pipeline 14, the primary pressure relief pipeline is connected with the buffer tank 7, and the secondary pressure relief pipeline is connected with the The dust remover 12 is connected with the secondary charging pipeline 8, and a feed valve and a material level monitor 13 are installed inside the housing, and the material level monitor is located at the top of the housing, and the feed valve The feed valve is connected with the discharge valve 2 through the transmission mechanism 4, and a material level monitor is installed on the top of the housing.

Embodiment 2

[0023] According to the biomass lock described in Embodiment 1, a primary pressure relief valve 6 is installed on the primary pressure relief pipeline, and a secondary pressure relief valve 11 is installed on the secondary pressure relief pipeline. A secondary charging valve 9 is installed on the secondary charging pipeline, and a gas sealing valve 15 is installed on the gas sealing pipeline.

Embodiment 3

[0025] According to the biomass lock described in embodiment 1 or 2, the housing is provided with a feed inlet, a feed outlet, a maintenance hole, a primary charging and pressure releasing hole, a secondary charging and pressure releasing hole and an air seal hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com