Auxiliary for improving pulverized coal gasification ash slag viscosity-temperature characteristics and preparation method

A technology of additives and ash, which is applied in the direction of fuel additives, petroleum industry, fuel, etc., can solve the problems affecting the stable operation of the gasifier and the sensitivity of slag viscosity to temperature changes, etc., to achieve improved viscosity-temperature characteristics and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

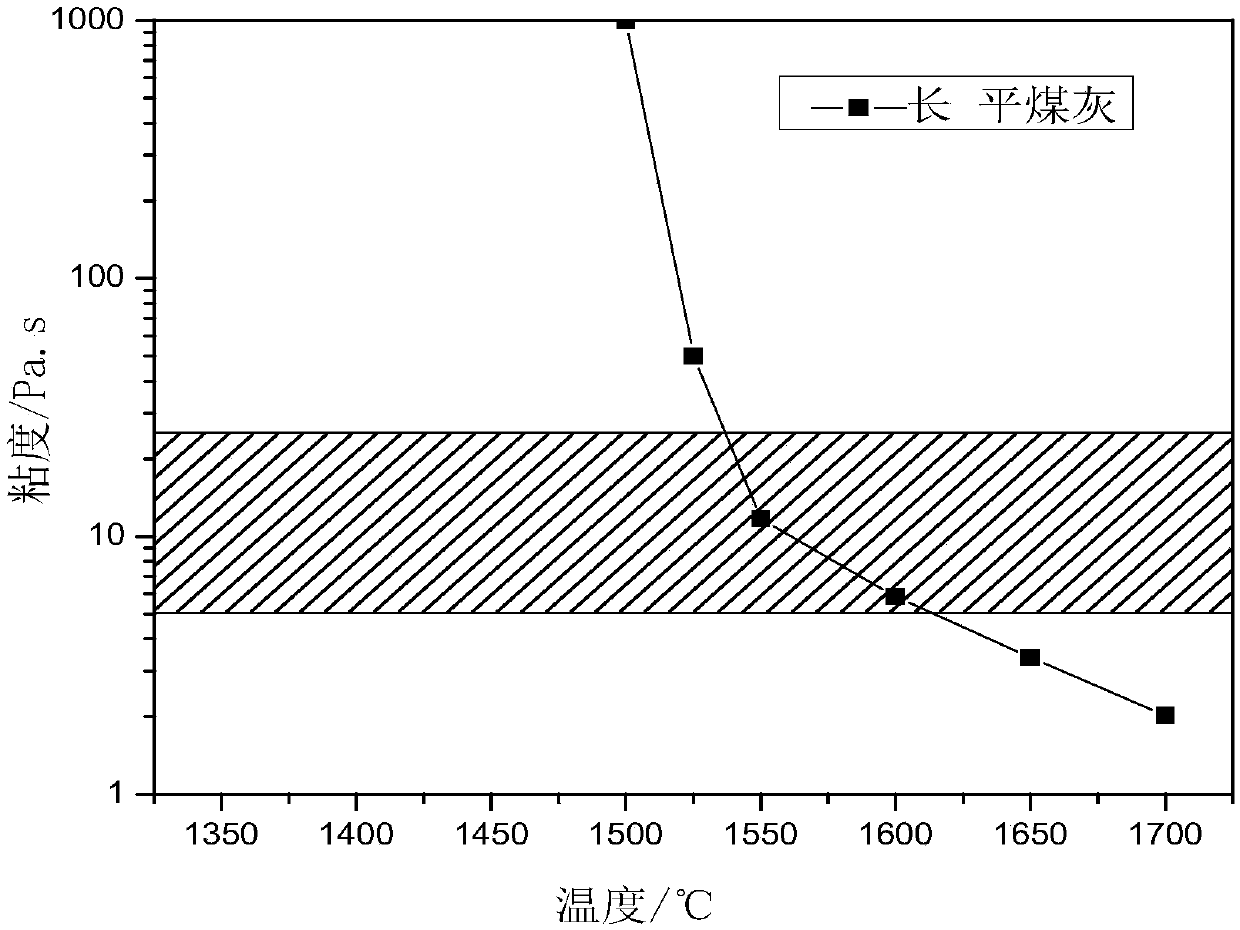

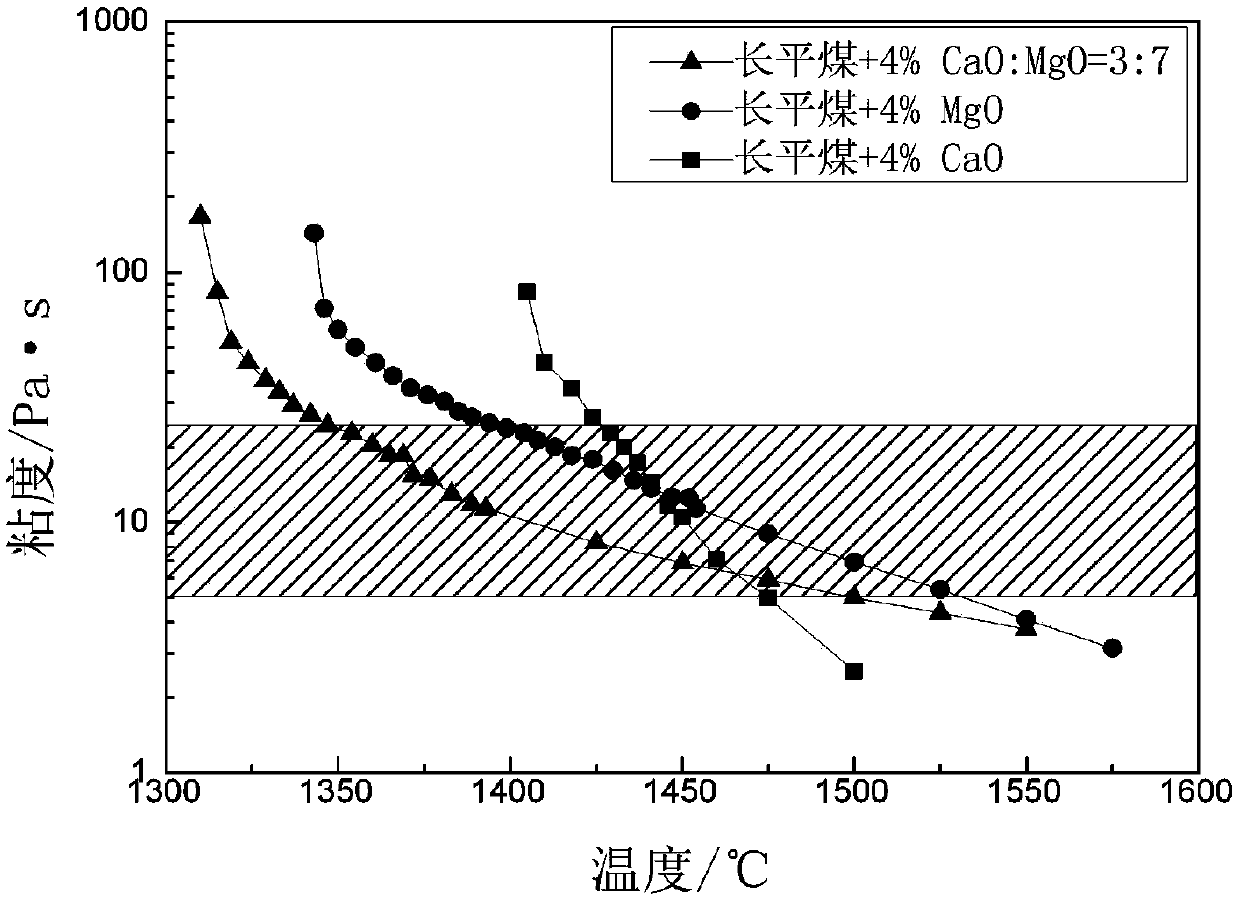

[0030] Example 1: The additive amount is 4% (coal-based), and the additive ratio is CaO:MgO=3:7, that is, the CaO additive ratio is 1.2% (coal-based), and the MgO additive ratio is 2.8% (coal-based), the composition of coal ash after adding additives is shown in Tables 2 and 3, the melting temperature of coal ash is shown in Table 4, and the viscosity-temperature characteristic curve of coal ash is shown in figure 2 .

Embodiment 2

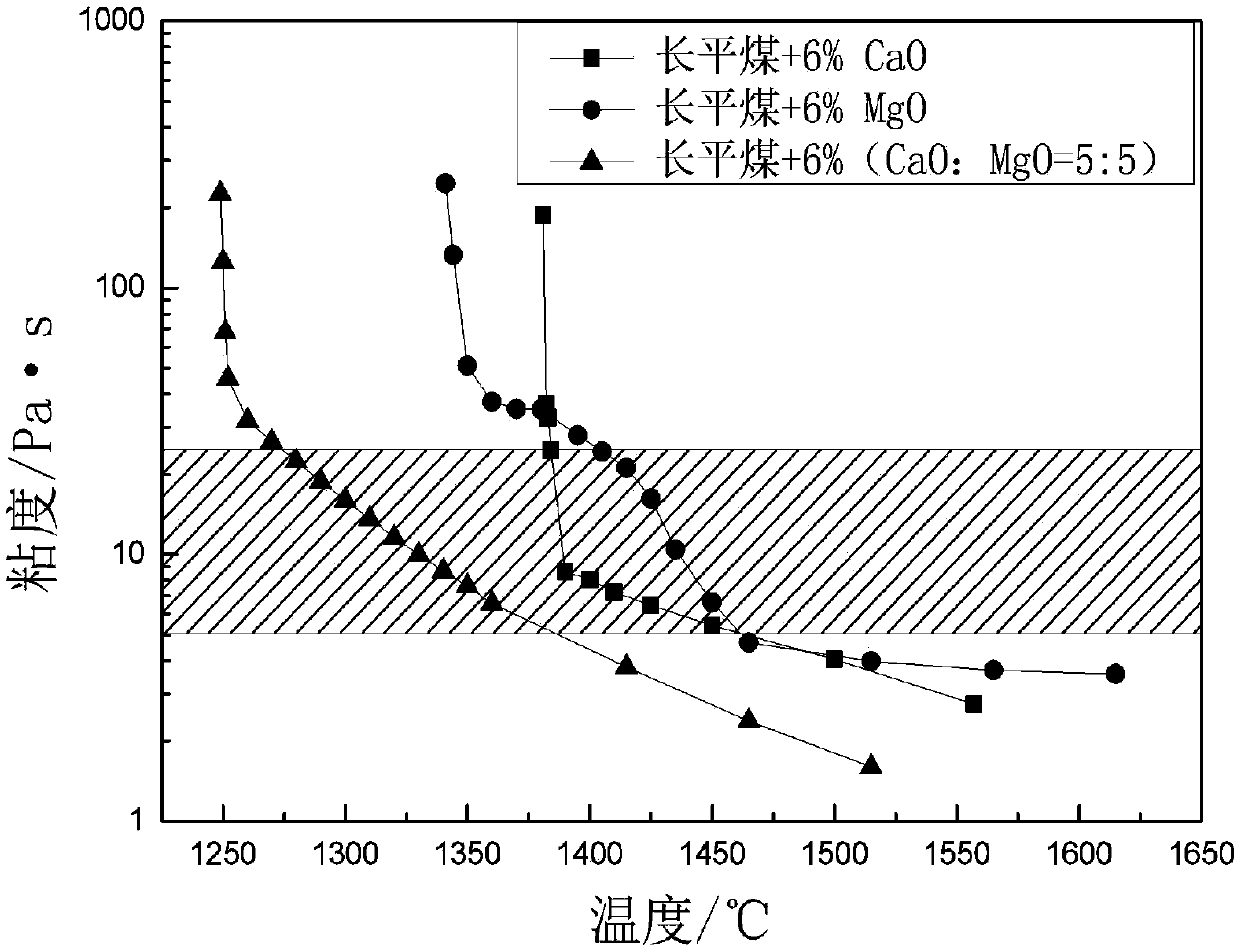

[0031] Example 2: The additive amount of the additive is 6% (coal-based), and the additive ratio is CaO:MgO=1:1, that is, the CaO additive ratio is 3.0% (coal-based), and the MgO additive ratio is 3.0% (coal-based), the composition of coal ash after adding additives is shown in Tables 2 and 3, the melting temperature of coal ash is shown in Table 4, and the viscosity-temperature characteristic curve of coal ash is shown in image 3 .

Embodiment 3

[0032] Embodiment 3: The addition amount of auxiliary agent is 3% (coal base), the addition ratio of auxiliary agent is CaO:MgO=2:1, namely CaO addition ratio is 2.01% (coal base), MgO addition ratio is 0.99% (coal-based), the composition of coal ash after adding additives is shown in Table 2 and 3, and the melting temperature of coal ash is shown in Table 4.

[0033] Table 1 Industrial analysis results of coal samples

[0034]

[0035] Among them, Aad-ash content, Vad-volatile matter.

[0036] Table 2 Coal ash composition of coal samples

[0037]

[0038] Among them: "coal sample + 4% CaO:MgO=3:7" refers to the additives blended in the coal sample with a mass addition of 4%, where the blending ratio of CaO and MgO is = 3:7, and so on .

[0039] Table 3 Main parameters of coal ash composition of coal samples

[0040]

[0041] Table 4 Coal sample coal ash melting temperature

[0042]

[0043] It can be seen from Tables 1 to 4 that the flow temperature of Changpin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com