A Composite Flux for Improving Fusibility of Coal Ash

A flux and melting technology, applied in fuel additives, solid fuel, petroleum industry, etc., can solve problems such as poor viscosity-temperature characteristics, affecting process, affecting gasifier slag discharge, etc., to improve viscosity-temperature characteristics, optimize The effect of operating space and improving the wall-mounted situation

Active Publication Date: 2019-12-06

山西杞望矿产品有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] With the maturity and rapid promotion and application of furnace types including aerospace furnaces and Jinhua furnaces in China, the research and development direction and market of coal gasification are gradually dominated by large-scale pressurized entrained entrained bed coal gasification gasifiers, and the promotion and application of liquid slagging gasifiers , which limits the use of coal with high ash melting point in a certain sense

[0003] Since most of the gasifiers currently in operation in China adopt the method of liquid slag removal, the ash melting point and viscosity-temperature characteristics are very important for the slagging process of the gasifier. If the temperature in the furnace is too high, the coal ash will The viscosity is reduced, and the coal ash cannot adhere to the furnace wall of the gasifier, which cannot effectively protect the gasifier

If the temperature in the furnace is too low, the viscosity of the coal ash will be too high, and the coal ash will easily stick to the furnace wall and even block the slag discharge port, which will affect the normal slag discharge of the gasifier run

[0004] In order to satisfy liquid slagging of coal with high ash melting point (ash flow temperature > 1580°C, which exceeds the measurement range of traditional ash melting point testers), the gasifier generally operates at a temperature 50-100°C higher than the ash melting point, which will mainly cause the following problems : 1. Coal pyrolysis gasification is above 950°C, and the control is higher than 1400°C. This temperature space needs to consume a lot of energy to realize it. Lowering the operating temperature of the gasifier is an effective way to reduce the consumption of the coal gasification system; 2. High temperature 3. Poor viscosity-temperature characteristics will cause the coal ash to flow in a narrow temperature range, and the control range for the process operation is small. The operation of the gasifier is difficult and the stability is poor. It is easy to cause slagging or poor slag hanging on the wall to cause gasifier shutdown accidents

However, there are many problems in production practice, such as the instability of hanging slag caused by coal blending; the corrosion problem caused by the dissolution of sodium salt in the gray water system; the problem of high ash content caused by the ineffective effect of magnesium salt

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

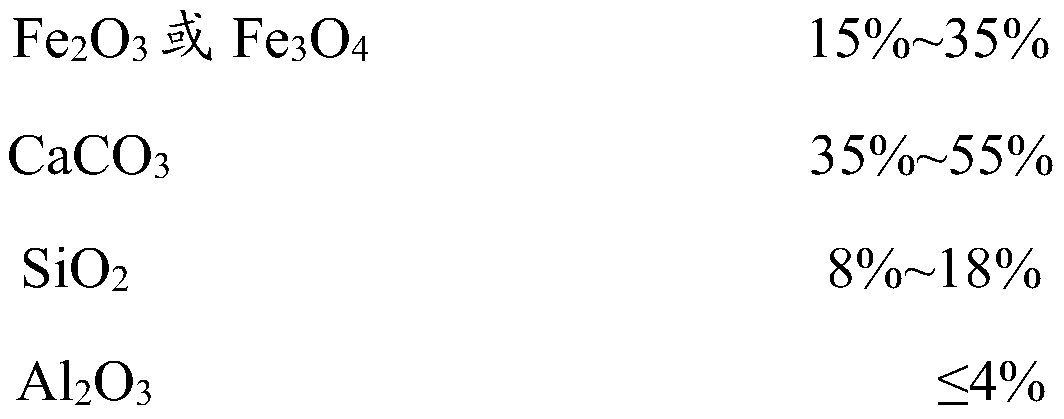

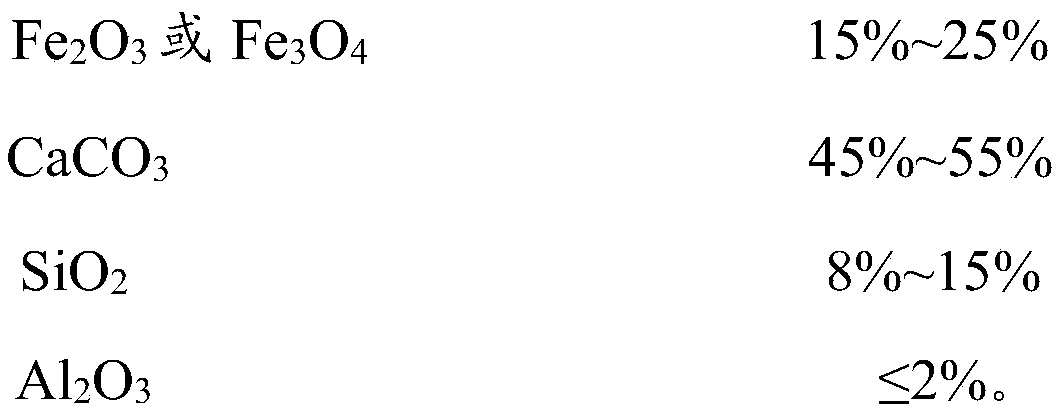

[0045] Table 1 shows some examples of the specific content of each component in the composite flux for improving the fusibility of coal ash according to the present invention. It should be pointed out that the specific content of each component of the coal ash fusible composite flux of the present invention is not limited to the data in Table 1.

[0046] Table 1 Composite flux component content embodiment

[0047]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a composite flux for improving fusibility of coal ash and belongs to the technical field of improving the fusibility of the coal ash. According to the composite flux, the problems that a method for improving the fusibility of the coal ash has high cost, cannot adjust the viscosity-temperature characteristics of the coal ash while reducing an ash fusion point can be solved.The raw materials of the flux comprise easily-obtained industrial raw materials such as limestone, iron ore and silica sand; the silica sand is mainly used for adjusting the silica-alumina ratio of atarget coal type; the addition proportion is determined according to ash compositions of the target coal type; the addition amount is 4 to 6 percent of the mass of raw coal. The composite flux disclosed by the invention has the advantages that the fusibility of the coal ash is effectively improved, the requirement on mixing uniformity can be ensured and the needs on environmental protection and stable production can be met.

Description

technical field [0001] The invention relates to the technical field of improving the fusibility of coal ash, in particular to a composite flux for improving the fusibility of coal ash. Background technique [0002] With the maturity and rapid promotion and application of furnace types including aerospace furnaces and Jinhua furnaces in China, the research and development direction and market of coal gasification are gradually dominated by large-scale pressurized entrained entrained bed coal gasification gasifiers, and the promotion and application of liquid slagging gasifiers , which limits the use of coal with high ash melting point in a certain sense. [0003] Since most of the gasifiers currently in operation in China adopt the method of liquid slag removal, the ash melting point and viscosity-temperature characteristics are very important for the slagging process of the gasifier. If the temperature in the furnace is too high, the coal ash will As the viscosity decreases...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10L9/10C10L10/00

CPCC10L9/10C10L10/00

Inventor 周志刚

Owner 山西杞望矿产品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com