Low temperature resistant shield tail sealing grease and preparation method thereof

A shield tail sealing, low temperature resistance technology, applied in the direction of lubricating composition, etc., can solve the problems of large influence of temperature fluctuation, reduce shield tail sealing effect, increase grease hardness, etc., to improve low temperature fluidity, broad application prospects, The effect of excellent low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

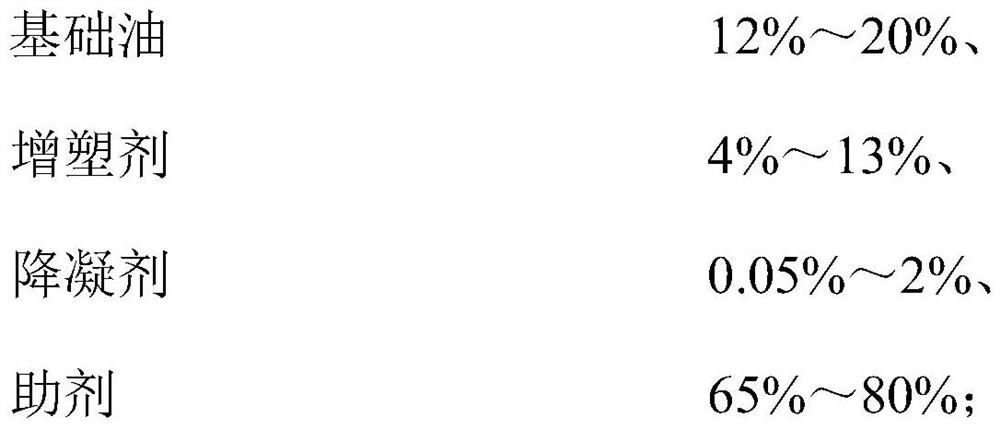

[0077] The present invention also provides a method for preparing the above-mentioned low-temperature-resistant shield tail sealing grease, comprising the following steps:

[0078] The base oil, plasticizer, pour point depressant and auxiliary agent are mixed.

[0079] In one of the embodiments, the preparation method of the above-mentioned low temperature resistant shield tail sealing grease comprises the following steps:

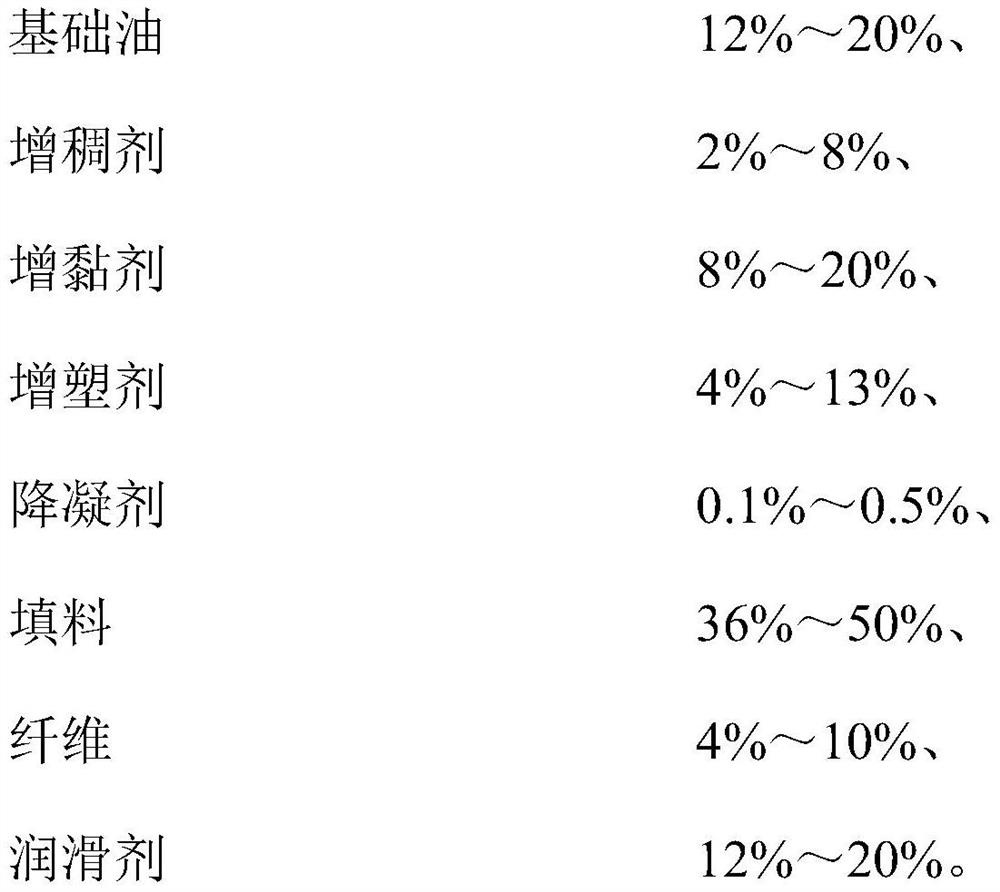

[0080] The base oil, thickener, tackifier, plasticizer, pour point depressant, filler, fiber and lubricant are mixed.

[0081] In one of the embodiments, the above-mentioned low-temperature-resistant shield tail sealing grease is mixed with the base oil, thickener, tackifier, plasticizer, pour point depressant, and filler under stirring at 40°C to 80°C , fibers and lubricants are mixed.

[0082] Preferably, the preparation method of the low temperature resistant shield tail sealing grease comprises the following steps:

[0083] Add a pour point depressa...

Embodiment 1

[0092] This embodiment provides a low temperature resistant shield tail sealing grease and a preparation method thereof.

[0093] (1) In terms of mass percentage, the composition of low temperature resistant shield tail seal grease 1 is as follows:

[0094] Base oil 150SN 15%, polymethacrylate (kinematic viscosity at 100°C is 400mm 2 / s; the degree of pour point reduction for base oil is 16) 0.2%, and the kinematic viscosity of polyisobutylene (100°C) is 230mm 2 / s) 7%, liquid rosin resin (kinematic viscosity at 100°C is 250mm 2 / s) 4%, dioctyl oxalate 5%, industrial petrolatum 1%, organic bentonite 5%, lignocellulose (length 1mm ~ 2mm) 5.5%, light calcium carbonate 42%, 2# lithium base grease 15.3 %.

[0095] (2) Preparation of low temperature resistant shield tail seal grease 1:

[0096] Set the temperature of the kneader to 60°C, add base oil 150SN to it, and add polymethacrylate while stirring to prepare mixture A;

[0097] Set the temperature of the kneader to 70°C, ad...

Embodiment 2

[0105] This embodiment provides a low temperature resistant shield tail sealing grease and a preparation method thereof.

[0106] (1) In terms of mass percentage, the composition of low temperature resistant shield tail seal grease 2 is as follows:

[0107] Base oil 150SN 15%, polyethylene fumaric acid copolymer (kinematic viscosity at 100°C is 400mm 2 / s; the degree of pour point reduction for base oil is 18) 0.2%, and the kinematic viscosity of polyisobutylene (100°C) is 250mm 2 / s) 3%, guar gum (kinematic viscosity at 100°C is 250mm 2 / s) 8%, industrial petrolatum 3%, dioctyl phthalate 2%, organic bentonite 5.5%, lignocellulose (length 1mm ~ 2mm) 5.8%, light calcium carbonate 20%, talc 19.5%, 3# Lithium-based grease 6%, 2# Lithium-based grease 12%.

[0108] (2) Preparation of low temperature resistant shield tail seal grease 2:

[0109] Set the temperature of the kneader to 60°C, add base oil 150SN to it, and add polyethylene fumaric acid copolymer while stirring to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com