Base oil for refrigerating machine oil composition, refrigerating machine oil composition, and composition for refrigerating

A technology of refrigerating machine oil and base oil, applied in lubricating compositions, base materials, petroleum industry, etc., can solve the problems of low-viscosity refrigerating machine oil without energy-saving effect, improve refrigeration efficiency COP value, protect the environment, and improve boundary lubricity and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

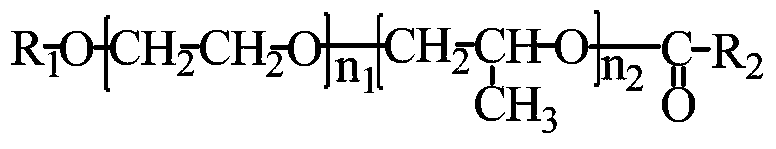

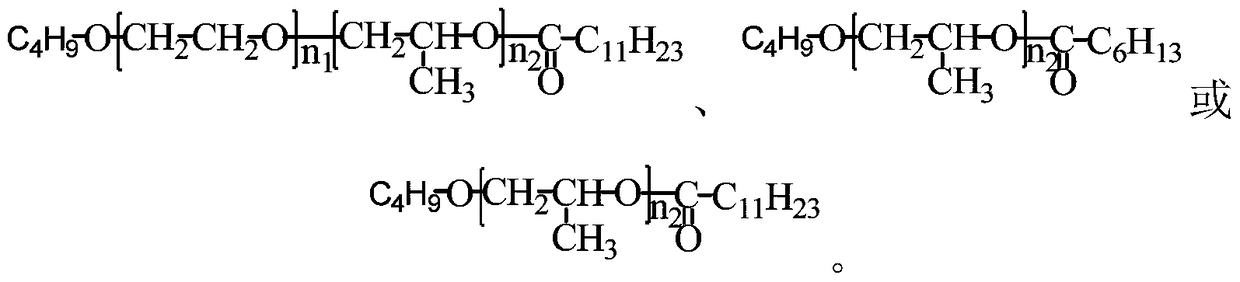

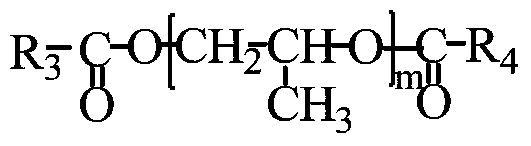

Method used

Image

Examples

preparation example Construction

[0049] The preparation of the refrigerating machine oil composition of the present invention has no special requirements, as long as the base oil for the refrigerating machine oil composition of the present invention is mixed with additives, the base oil for refrigerating machine oil composition can be obtained first, and then mixed with additives, or directly The components constituting the base oil for the refrigerating machine oil composition are directly mixed with additives to obtain the refrigerating machine oil composition, which is not particularly required in the present invention.

[0050] Preferably, the above additives are selected from one or more of lubricants, friction reducers, antioxidants, anticorrosion agents and antifoaming agents.

[0051] According to the refrigerating machine oil composition provided by the present invention, the above-mentioned additives and their contents can be various conventional additives and their conventional contents used in refr...

Embodiment 1

[0066] (1) Raw materials and consumption of base oil for refrigerating machine oil composition:

[0067] Alkylbenzene oil: commercially available from Pt.Unggul Indah Cahaya Tbk. (Indonesian company) produced alkylbenzene oil (it includes 10wt% decanylbenzene, 25wt% undecylbenzene, 35wt% dodecylbenzene Alkylbenzene and 30% tridecylbenzene, the kinematic viscosity at 40°C is 4.2mm 2 / s), consumption is 35 parts by weight;

[0068] Ester oil: Di-n-octyl 3-methyl adipate (kinematic viscosity at 40°C is 8.38mm 2 / s, the viscosity index is 170), and consumption is 45 parts by weight;

[0069] Another hydrocarbon oil different from alkylbenzene oil: Fischer-Tropsch synthetic isoparaffin (mainly composed of isoparaffin, kinematic viscosity at 40°C is 2.8 mm 2 / s, the pour point is -32°C, the boiling point is 270-280°C), and the dosage is 5 parts by weight.

[0070] (2) The method of mixing the base oil for the refrigerating machine oil composition: the above raw materials are mix...

Embodiment 2

[0074] (1) Raw materials and consumption of base oil for refrigerating machine oil composition:

[0075] Alkylbenzene oil: commercially purchased from Tianjin Baite Chemical Company, the main raw material is alkylbenzene oil of dodecylbenzene (the kinematic viscosity at 40°C is 4.2mm 2 / s), consumption is 60 parts by weight;

[0076] Ester oil: 1,10-decanediol bis(2-ethylhexyl) ester (kinematic viscosity at 40°C is 12.1mm 2 / s, viscosity index is 133), consumption is 30 weight parts;

[0077] Another hydrocarbon oil different from alkylbenzene oil: Hydrogenated isoparaffin produced by YOUGONG (Korea) company hydroisomerization process (its main component is isoparaffin, kinematic viscosity at 40°C is 3.2mm 2 / s, the pour point is -38°C, the boiling point is 270-280°C), and the dosage is 10 parts by weight.

[0078] (2) Method of mixing base oil for refrigerating machine oil composition: The above-mentioned raw materials were mixed to prepare the base oil for refrigerating m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com