An additive and its application for improving the viscosity-temperature characteristics of fly-coal gasification coal ash slag

A technology of additives and coal ash, which is applied in the direction of granular/powder fuel gasification, gasification process, petroleum industry, etc. It can solve the problem of coal ash slag viscosity being sensitive to temperature changes, and achieve the effect of improving viscosity-temperature characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

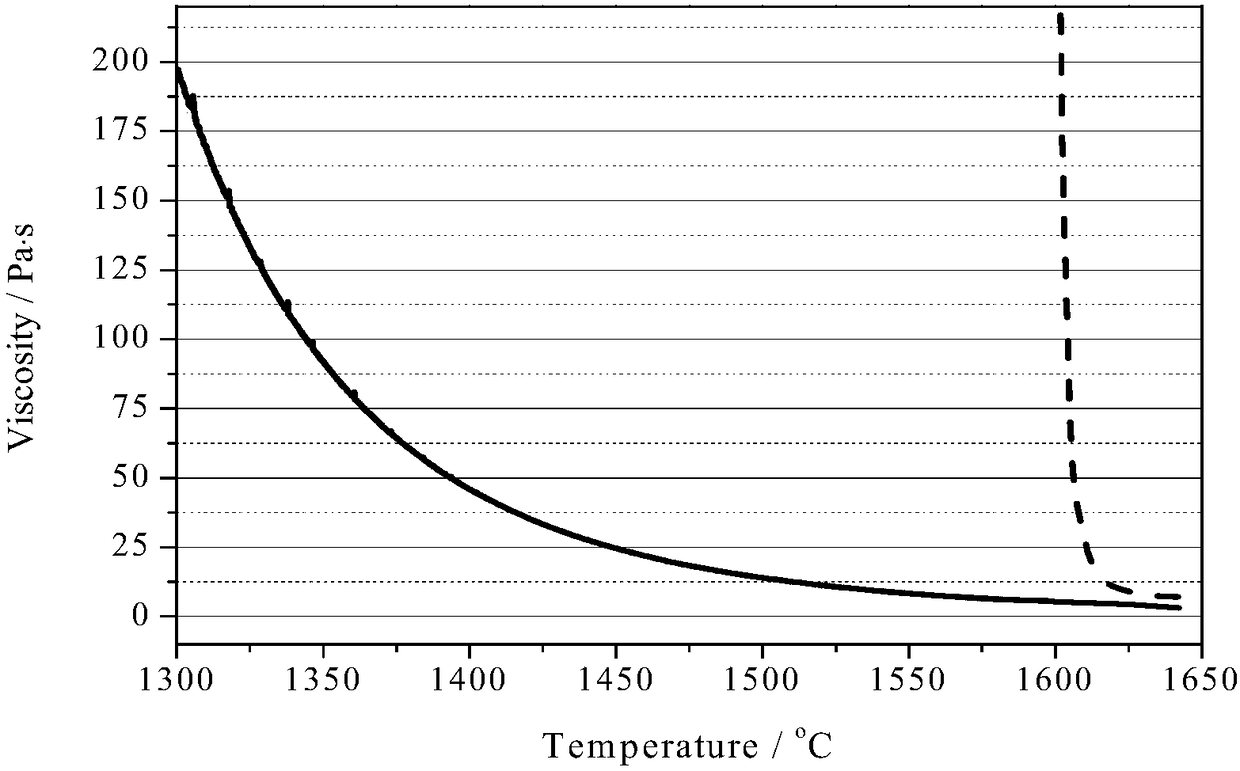

[0015] Will contain 93.62% CaSiO by mass percentage 3 , 1.0% Fe 2 o 3 , 2.5% Al 2 o 3 , 2.3% MgO additive, with particle size less than or equal to 80 mesh (≦180μm), 5.67% (based on coal) is added to Shanxi anthracite A coal, and mixed evenly. According to the method stipulated in the national standard "Measurement of Coal Ash Viscosity" (GB / T 31424-2015), the viscosity-temperature characteristics of coal ash slag of raw coal and coal samples with additives were measured, and it was found that the additive significantly improved coal ash melting. The viscosity-temperature characteristics of slag make the viscosity 25Pa. The temperature of s decreases from 1615°C to 1460°C, and the viscosity of coal ash slag changes slowly with temperature.

Embodiment 2

[0017] Will contain 95.00% CaSiO by mass percentage 3 , 0.8% Fe 2 o 3 , 1.6% Al 2 o 3 , 2.0% MgO additive, with particle size less than or equal to 80 mesh (≦180μm), 7% (based on coal) is added to Shanxi anthracite B coal, and mixed evenly. According to the national standard "Method for Determination of Coal Ash Viscosity" (GB / T 31424-2015), the viscosity-temperature characteristics of coal ash slag of raw coal and coal samples with additives were measured, and it was found that the additive significantly improved the viscosity of coal ash slag. temperature characteristics, making the viscosity 25Pa. s temperature decreased from 1635°C to 1450°C, and.

[0018] From figure 1 It can be seen that the uniform mixing of additives into Shanxi anthracite B significantly improved the viscosity-temperature characteristics of its coal ash slag, and not only reduced the viscosity of coal ash slag at high temperature, the viscosity was 25Pa. The temperature of s is reduced from abo...

Embodiment 3

[0020] Will contain 99.00% CaSiO by mass percentage 3 , 0.15% Fe 2 o 3 , 0.2% Al 2 o 3 , 0.3% MgO additive, with particle size less than or equal to 80 mesh (≦180μm), 8.91% (based on coal) is added to Shanxi anthracite C coal, and mixed evenly. According to the national standard "Method for Determination of Coal Ash Viscosity" (GB / T 31424-2015), the viscosity-temperature characteristics of coal ash slag of raw coal and coal samples with additives were measured, and it was found that the additive significantly improved the viscosity of coal ash slag. temperature characteristics, making the viscosity 25Pa. The temperature of s decreases from 1643°C to 1440°C, and the viscosity of coal ash slag changes slowly with temperature.

[0021] Shanxi Anthracite A of the present invention, B, the ash chemical composition of C is shown in Table 1

[0022] Table 1 Ash chemical composition of Shanxi anthracite coal samples

[0023] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com