Composite coal and method for improving viscosity-temperature characteristics of coal ash and its application

A technology of coal ash and characteristics, applied in solid fuel, granular/powder fuel gasification, petroleum industry, etc., can solve the problems of reducing the viscosity of coal ash, a large amount of ash and slag, increasing costs, etc., to improve the viscosity-temperature characteristics, The effect of reducing the generation of solid ash and reducing the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment is used to illustrate the composite coal of the present invention and the method for improving the viscosity-temperature characteristics of coal ash.

[0053] The adjusted coal ZN and the raw coal MD whose viscosity-temperature characteristics are to be improved are uniformly mixed at a weight ratio of 3:1 to obtain composite coal I.

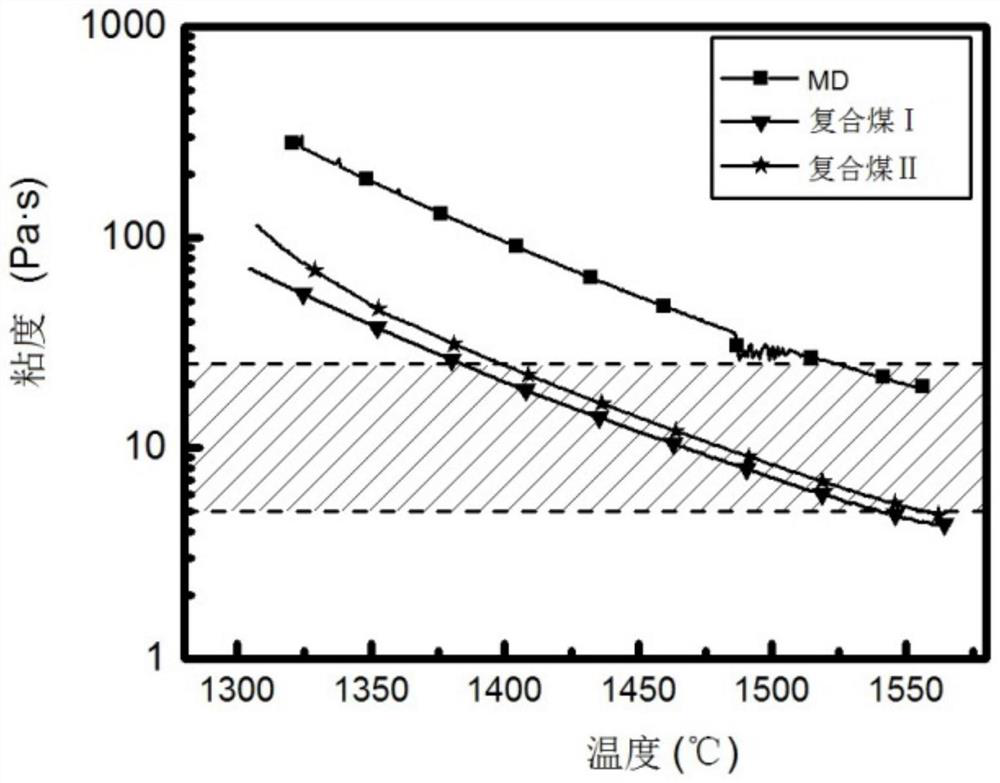

[0054] The coal ash viscosity-temperature characteristic curve of the prepared composite coal is as follows: figure 1 shown.

Embodiment 2

[0056] This embodiment is used to illustrate the composite coal of the present invention and the method for improving the viscosity-temperature characteristics of coal ash.

[0057] The adjusted coal ZL and the raw coal MD whose viscosity-temperature characteristics are to be improved are uniformly mixed at a weight ratio of 3:1 to obtain composite coal II.

[0058] The coal ash viscosity-temperature characteristic curve of the prepared composite coal is as follows: figure 1 shown.

Embodiment 3-4

[0060] The adjusted coal is mixed with the raw coal whose viscosity-temperature characteristics are to be improved to obtain composite coal. The types and weight ratios of the adjusted coal and raw coal are shown in Table 4.

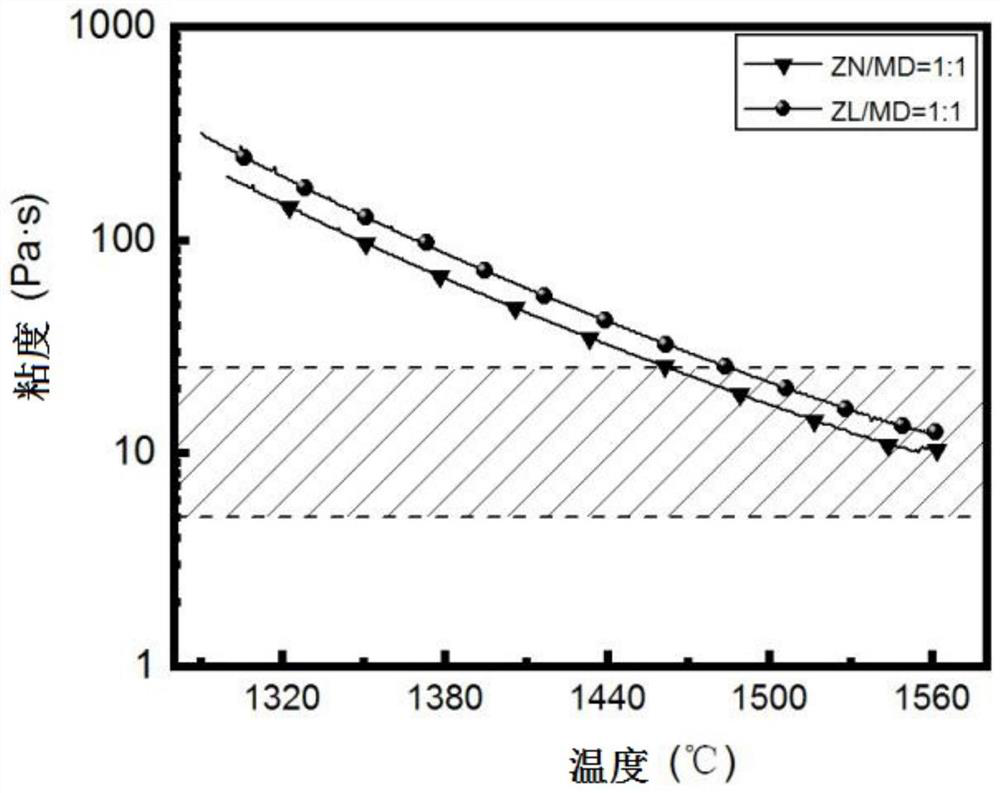

[0061] The coal ash viscosity-temperature characteristic curve of the prepared composite coal is as follows: image 3 shown. The temperature of the composite coal when the viscosity is 25Pa·s, coal ash content and (SiO 2 +Al 2 o 3 +TiO 2 ) / (Fe 2 o 3 +CaO+Na 2 O+K 2 O+MgO), the results are also shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com