A method for establishing a hazardous waste incineration rotary kiln shell

A hazardous waste and rotary kiln technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of lack of firmness and anti-stripping effect of the kiln skin, low temperature at the outlet of the rotary kiln, and single kiln skin material, etc., to achieve the establishment of The method is simple, the operation cost is reduced, and the applicability is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

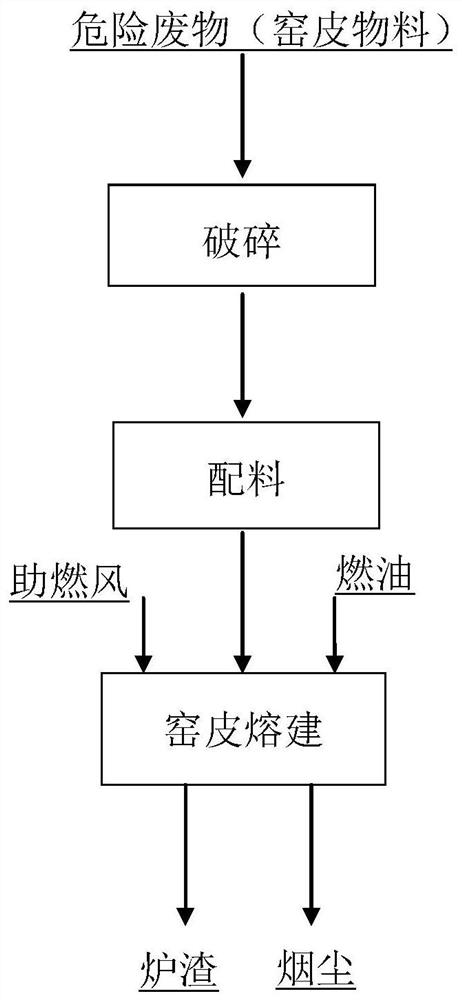

[0037] A method for establishing a hazardous waste incineration rotary kiln shell, the schematic diagram of the process flow is as follows figure 1 As shown, the specific process of the method is as follows:

[0038] The ingredients for building the kiln skin are hazardous waste, including the following materials in parts by weight: 5 parts of grinding mud, 20 parts of wire drawing aluminum mud, 10 parts of calcium-containing sludge, 8 parts of waste quartz sand, 18 parts of waste plastic, 6 parts of glass bottles, 16 parts of waste kaolin, 15 parts of waste engine oil.

[0039] Among the above materials, grinding mud, wire drawing aluminum sludge, and waste engine oil are from HW08 waste mineral oil; calcium-containing sludge, waste quartz sand, waste plastics, and waste glass bottles are from HW49 other wastes; waste kaolin is from HW02 medical waste.

[0040] A kiln shell is built for a hazardous waste rotary kiln with a processing capacity of 58t / d, and 120 tons of materi...

Embodiment 2

[0045] A method for establishing a hazardous waste incineration rotary kiln shell, the specific process of the method is as follows:

[0046] The ingredients for building the kiln skin are hazardous waste, including the following materials in parts by weight: 5 parts of polishing powder, 20 parts of aluminum packaging, 10 parts of waste gypsum, 8 parts of waste quartz mud, 18 parts of waste rubber, and 5 parts of waste glass bottles 18 parts of waste oil sludge, 16 parts of waste kaolin, 2 parts of waste brazing flux.

[0047]Among the above materials, polishing powder, waste oil sludge, and waste kaolin come from HW08 waste mineral oil; aluminum packaging, waste gypsum, waste quartz mud, and waste glass bottles come from other wastes in HW49; waste rubber comes from HW13 organic resin waste; waste hard Flux is derived from HW17 surface treatment waste.

[0048] A kiln shell is built for a hazardous waste rotary kiln with a processing capacity of 24t / d, and 60 tons of materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com