Feeding apparatus of biomass silo

A feeding device, biomass technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of shed material, bridging, poor fluidity, unstable system operation, etc., to achieve strong pertinence, high Powerful, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

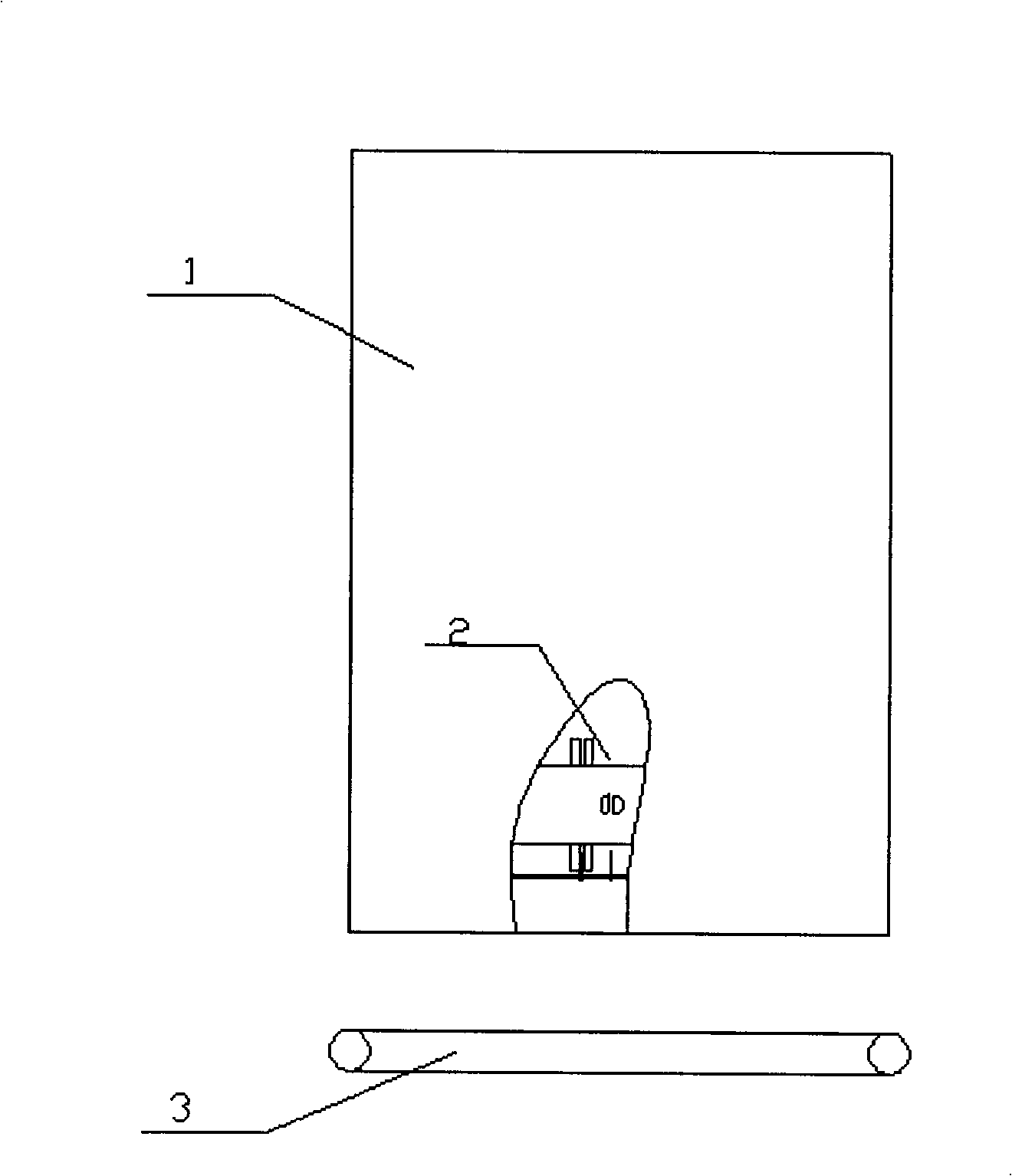

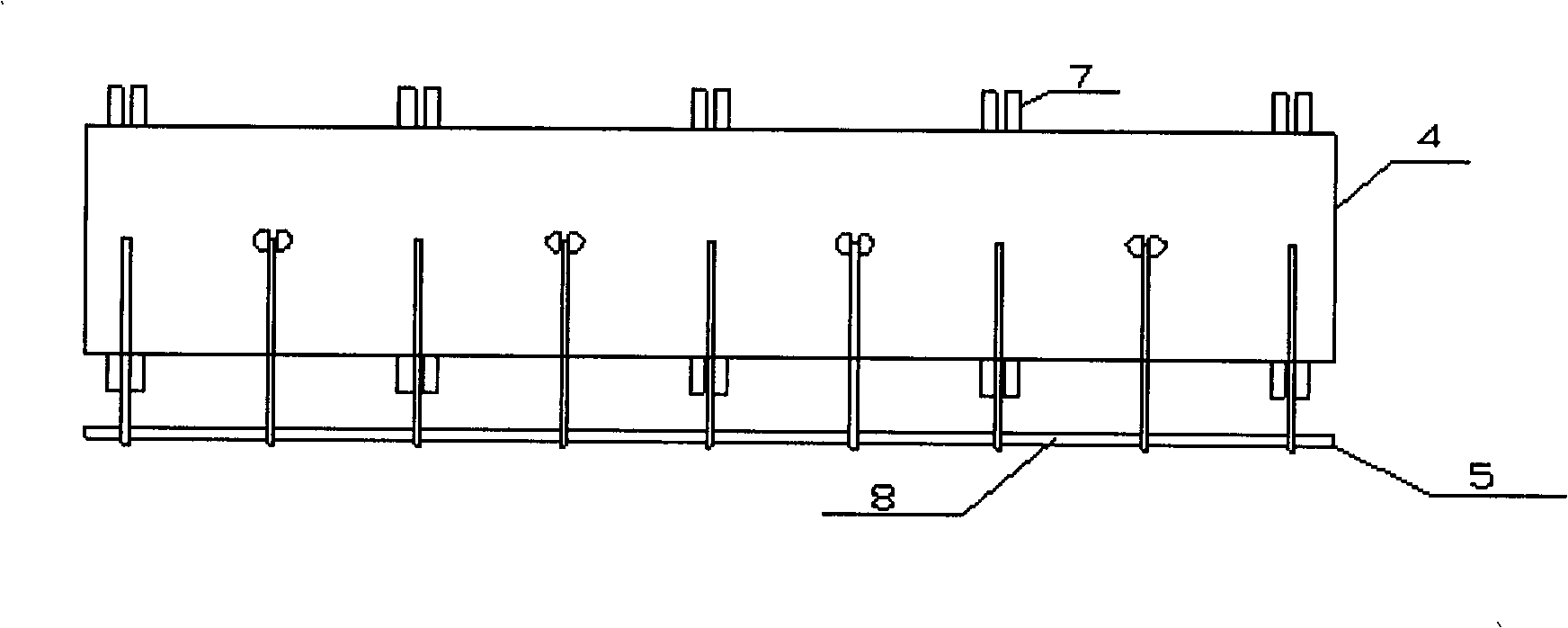

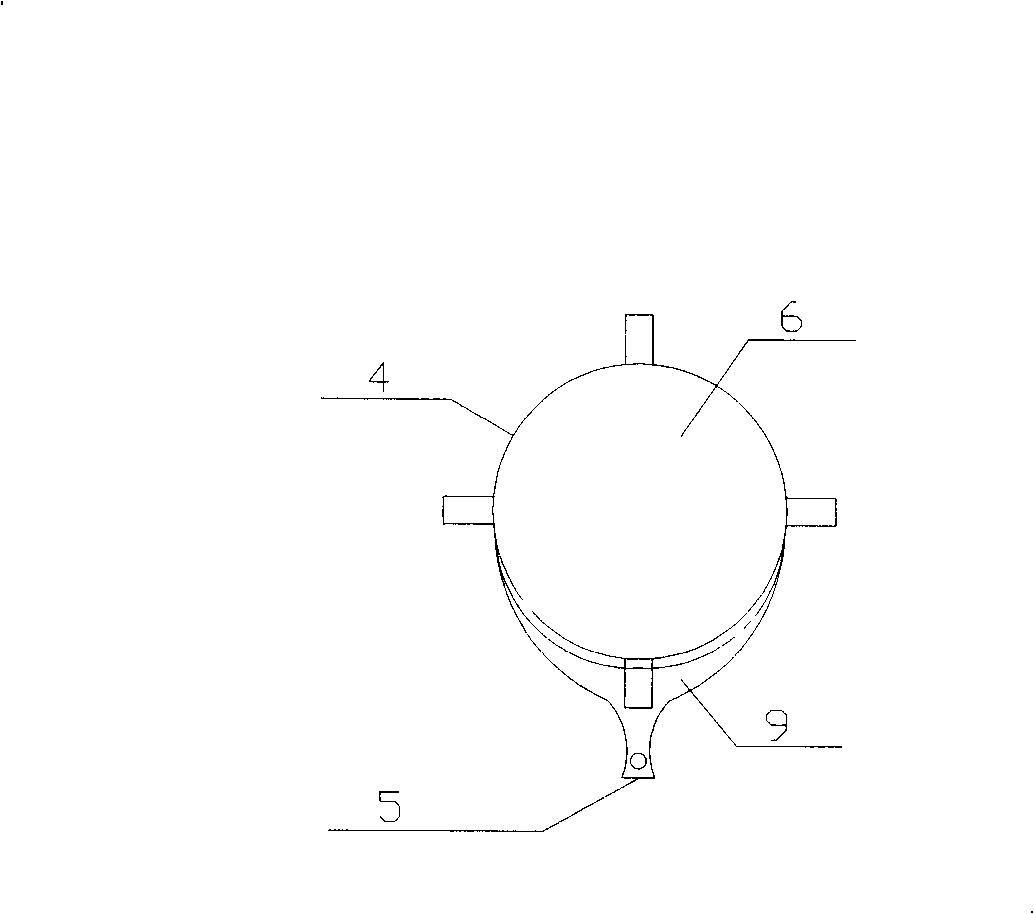

[0017] The feeding device for biomass includes a silo 1, a feeding device 2 and a conveying device 3. The lower part of the silo 1 is provided with a feeding device 2, and the bottom of the silo 1 is provided with a conveying device 3. The feeding device 2 includes parallel placement A plurality of pushers 4 and broken winders 5, the pusher 4 has a pusher shaft 6, on the pusher shaft 6, a plurality of stick groups are arranged at equal distances in the axial direction, and each stick group is on the pusher shaft 6. There are 1 to 6 material-moving stick pairs 7 in the radial direction. The broken winder 5 has a fixed shaft 8 on which a scraper 9 matched with the material-moving stick pairs 7 is provided.

[0018] The pair 7 of the material-moving sticks is two sticks, and the distance between the two sticks is 1-50mm. The scraper 9 is a crescent-shaped scraper, and the crescent-shaped scraper is arranged in the gap between the pair of material-moving sticks 7. The conveying d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com