Purification method for PAN-based carbon fiber production waste gas

A waste gas purification and carbon fiber technology, applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve problems such as easy blockage of equipment, difficulty in waste heat recovery, easy blockage of combustion equipment, etc., to ensure normal operation and reduce the concentration of particulate matter , The effect of continuous and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

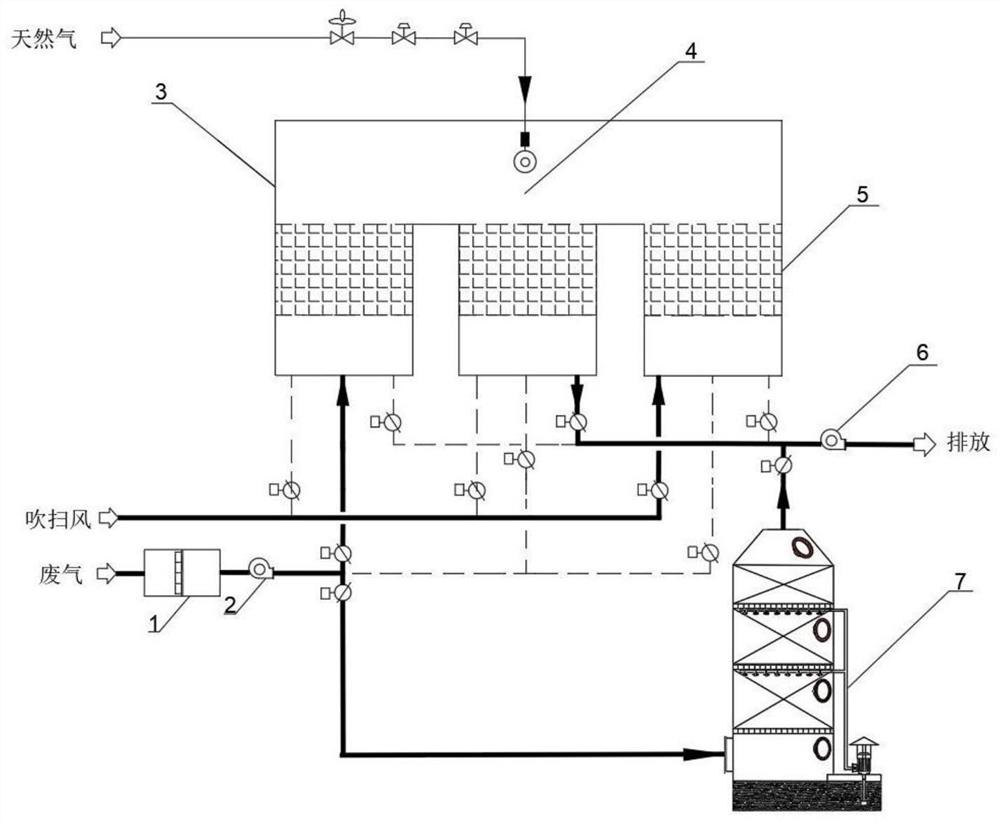

Method used

Image

Examples

Embodiment 1

[0033] The scheme of the present invention is applied in the waste gas treatment of 160 tons of polyacrylonitrile carbon fiber production in a certain carbon fiber enterprise, and its specific circumstances are as follows:

[0034] (1) During the production process of PAN-based carbon fiber, the exhaust gas of the oxidation furnace, the exhaust gas of the low-temperature carbonization furnace and the exhaust gas of the high-temperature carbonization furnace are mixed and sent to the filter through the fan, and the exhaust gas volume is 1.1×10 4 m 3 / h, the concentration of particulate matter in the main pollutants is 8.5mg / m 3 , HCN concentration 2.7mg / m 3 , NH 3 Concentration 12.4mg / m 3 . The filter is equipped with low, medium and high-efficiency three-layer polytetrafluoroethylene filter cotton, and a differential pressure gauge is installed at both ends of the filter inlet and outlet. When the pressure loss of the filter exceeds 1000Pa, it should be cleaned or replaced...

Embodiment 2

[0038] The scheme of the present invention is applied in the waste gas treatment of 500 tons of polyacrylonitrile carbon fiber production in a certain carbon fiber enterprise, and its specific circumstances are as follows:

[0039] (1) During the production process of PAN-based carbon fiber, the exhaust gas from the oxidation furnace, the exhaust gas from the low-temperature carbonization furnace and the exhaust gas from the high-temperature carbonization furnace are mixed and sent to the filter through the fan, and the exhaust gas volume is 3.5×10 4 m 3 / h, the concentration of particulate matter in the main pollutants is 10.2mg / m 3 , HCN concentration 2.5mg / m 3 , NH 3 Concentration 13.6mg / m 3 . The filter is equipped with a low-medium-high-efficiency three-layer PTFE filter plate, and a differential pressure gauge is installed at both ends of the filter inlet and outlet. When the pressure loss of the filter exceeds 1200Pa, it should be cleaned or replaced in time. The part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com