Refining and reclaiming technology of tail gas absorption solvent in production of toluene diisocyanate

A technology for toluene diisocyanate and tail gas absorption, which is applied in the purification/separation of isocyanic acid derivatives, purification/separation of hydrocarbons, separation methods, etc. Adverse effects and other issues, to achieve the effect of reducing operating costs and equipment costs, avoiding operating costs and maintenance costs, and reducing operating and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

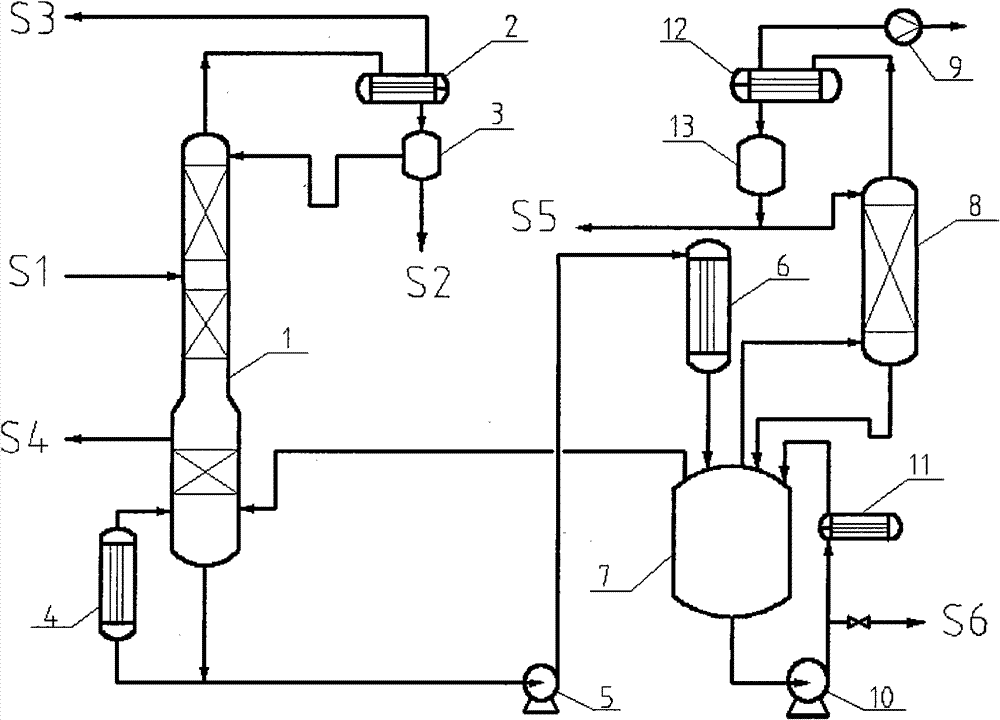

Image

Examples

Embodiment 1

[0028] The solvent used in this embodiment is toluene, but not limited to toluene. The atmospheric pressure where the TDI device is located is 0.84 bar.

[0029] 1. The flow rate of logistics S1 is 2992kg / h, which contains phosgene 4.6kg / h, TDI10.2kg / h, DEIP4.2kg / h, the rest is toluene and a small amount of other impurities, and the feed temperature is 160°C (determined by the previous process) , continuously and stably fed from the middle of the atmospheric refining tower 1, the gas phase at the top of the tower is condensed in the condenser 2, the condensation temperature is 40-60°C, the condensate enters the reflux tank 3, overflows back to the top of the tower, and serves as the reflux of the tower, reflux Part of the material S2 is regularly discharged from the bottom of the tank 3, neutralized with caustic soda solution and then incinerated to avoid the accumulation of light components other than phosgene such as water and carbon tetrachloride in the system; the unconden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com