Effective slurry thick and stable discharging device and method

A discharge device and dense technology, applied in chemical instruments and methods, separation methods, feeding/discharging devices of settling tanks, etc., can solve problems affecting the normal production of the filling system, low production capacity, and large floor space. Achieve the effects of solving propagation attenuation and radiation blind spots, saving costs, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0022] The invention provides a high-efficiency slurry thickening and stable discharge device and method.

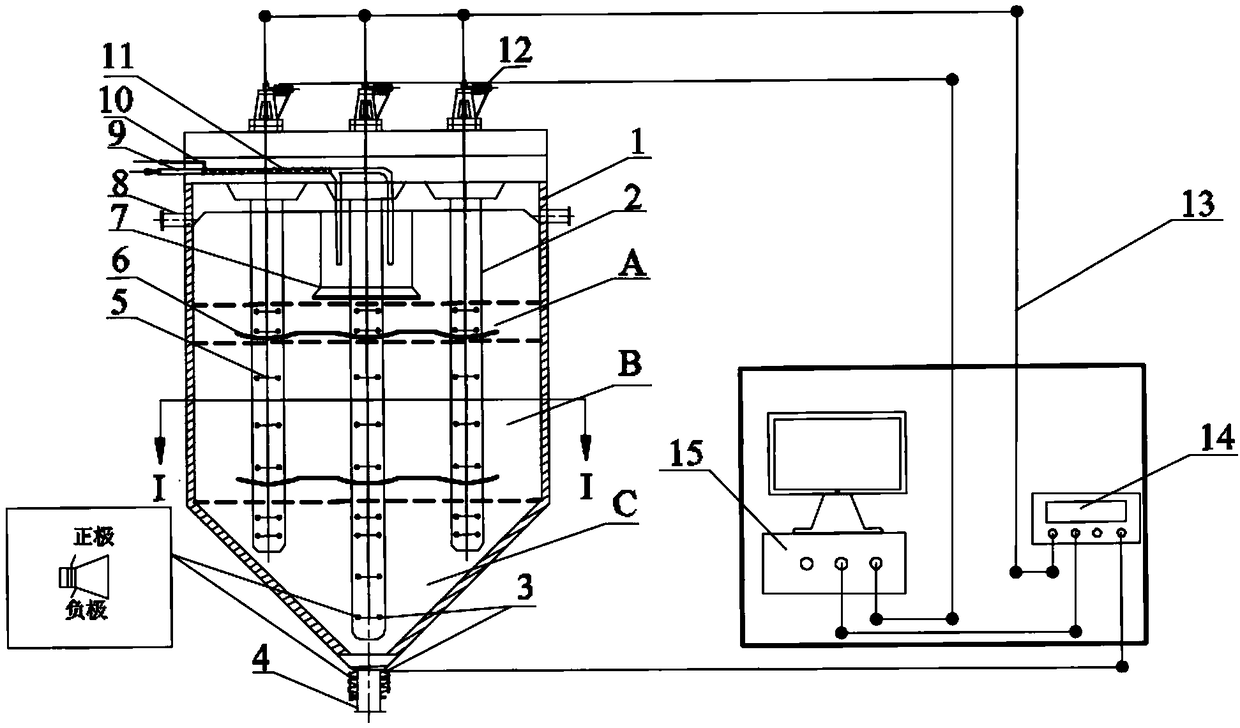

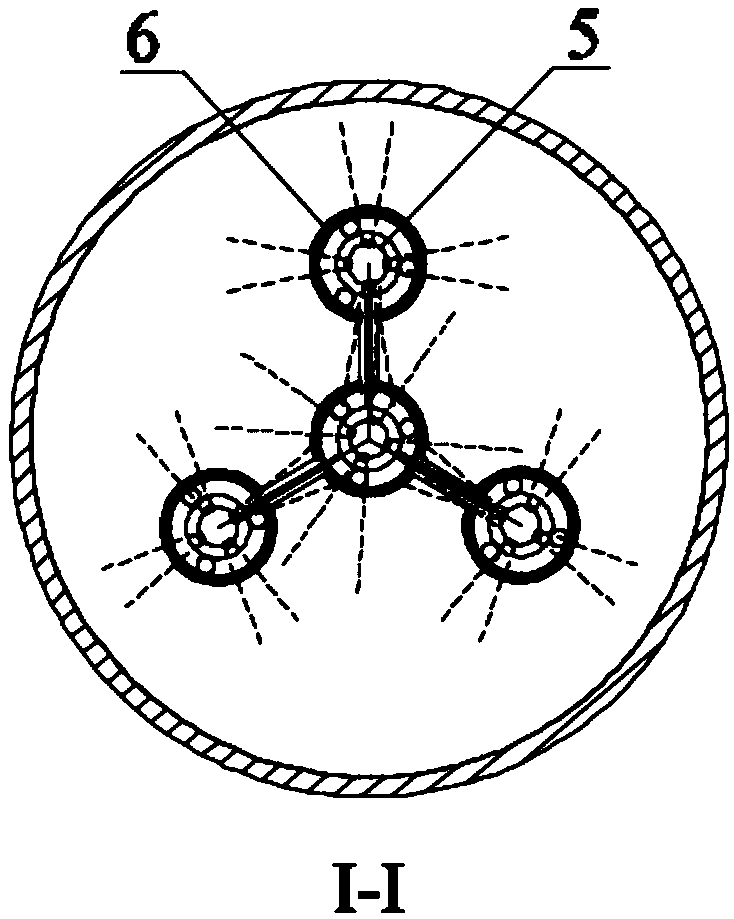

[0023] Such as figure 1 with figure 2 As shown, the device includes a bin body 1, a transducer carrier tube 2, an acoustic / ultrasonic transducer 3, a sand outlet 4, a transducer serial line 5, a carrier tube stabilizer 6, a steady flow cylinder 7, an overflow Pipe 8, feeding pipe 9, flocculant pipe 10, mixing spiral pipe 11, rotation drive device 12, transducer connection line 13, sound / ultrasonic generator 14 and numerical control 15, the transducer carrier pipe 2 is located in the warehouse Inside the body 1, the transducer carrier tube 2 is connected to the carrier tube stabilizer 6, the upper part of the transducer carrier tube 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com