Device and method for preparing hydrogen through temperature controlled continuous decomposition of hydrogen sulfide

A hydrogen sulfide, warm-type technology, applied in the production of hydrogen and other directions, can solve the problems of unstable discharge, no mention of H2 energy efficiency and stability problems, and reduced decomposition rate, so as to reduce energy loss, facilitate industrialization, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

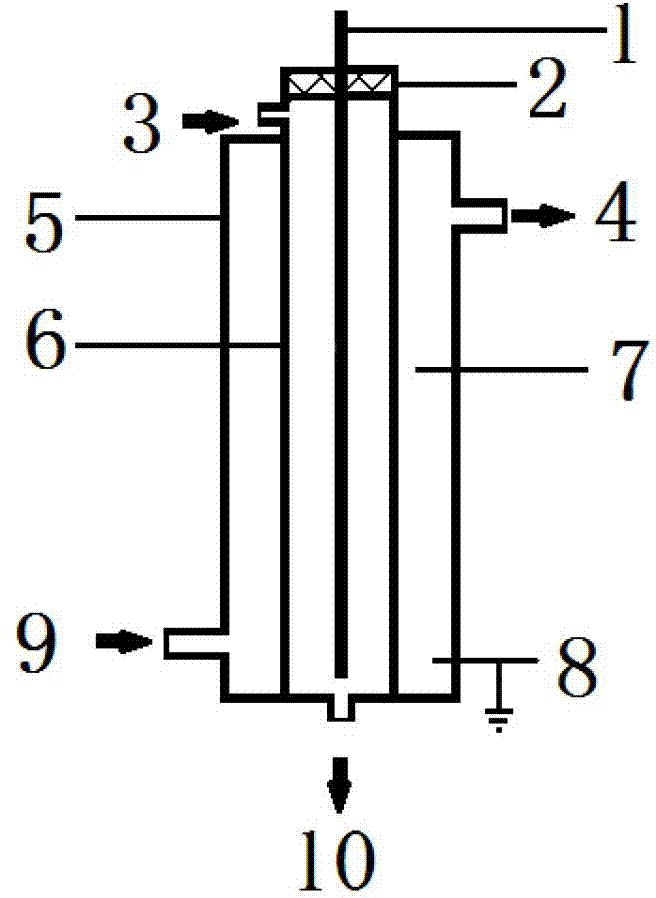

[0028] A device for producing hydrogen by continuous decomposition of temperature-controlled hydrogen sulfide, such as figure 1 As shown, it is a temperature-controllable plasma generator belonging to dielectric barrier discharge. Its shell is a coaxial sleeve structure made of insulating material. The upper part of the outer cylinder (5) and the inner cylinder (6) and The lower part is sealed to form a jacket (7). In the jacket (7) is a circulating liquid used as a temperature-controlling and grounding electrode. The top of the inner cylinder (6) is sealed with an insulating head. The center electrode (1) is inserted into the inner cylinder (6), and the part protruding from the insulating material is connected to the high-voltage end of the AC step-up transformer, and a metal electrode is fixed at the lower part of the ring gap between the outer cylinder (5) and the inner cylinder (6). One end of the current lead-out wire goes deep into the jacket (7) to contact the liquid gr...

Embodiment 2

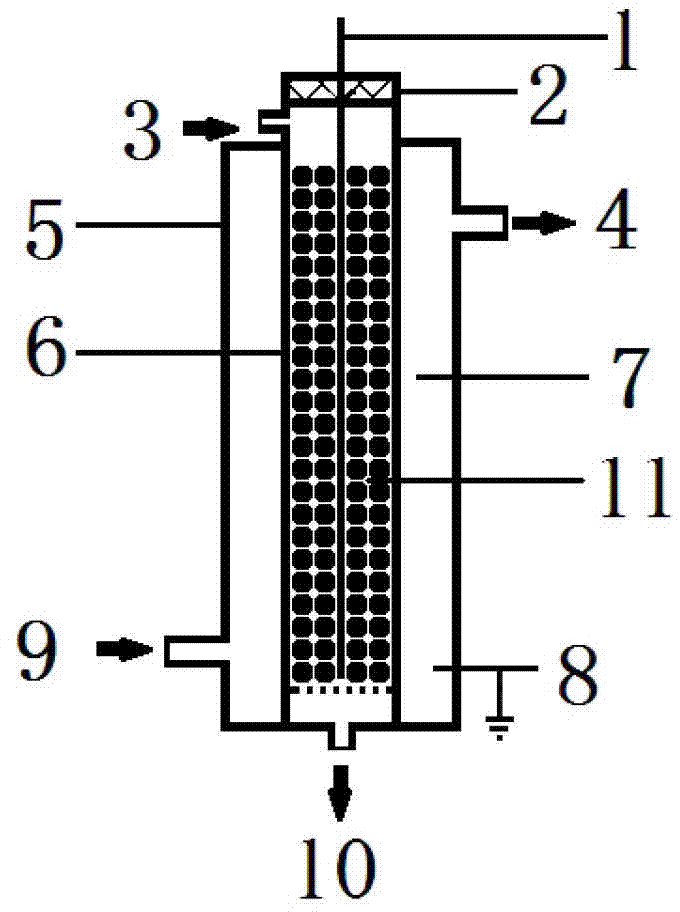

[0035] A device for producing hydrogen by continuous decomposition of temperature-controlled hydrogen sulfide, such as figure 2 As shown, it is a temperature-controllable plasma generator belonging to dielectric barrier discharge. Its shell is a coaxial sleeve structure made of insulating material. The upper part of the outer cylinder (5) and the inner cylinder (6) and The bottom is sealed to form a jacket (7). In the jacket (7) is a circulating liquid grounding electrode for temperature control and grounding. The top of the inner cylinder (6) is sealed with an insulating head. The center electrode (1) is inserted into the inner cylinder (6) from the center, and the part protruding from the insulating material is connected to the high-voltage end of the AC step-up transformer, and a A metal current lead-out wire, one end of which goes deep into the jacket (7) and contacts the liquid grounding electrode, and the other end extends out of the outer cylinder (5) to connect with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com