Method for treating goaf by harmlessly filling phosphate tailings

A technology for phosphate tailings and goafs, applied in chemical instruments and methods, separation methods, ground mining, etc., can solve the problems of poor dewatering effect of high-efficiency automatic filter presses and the inability to directly pile tailings, and achieve safety and environmental protection. Simple and feasible, reduce storage costs, and have the effect of continuous and stable discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

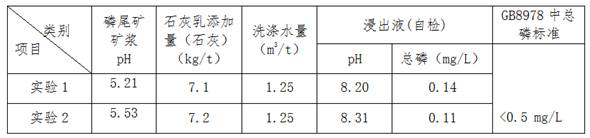

[0031] Embodiment 1, a method for harmless filling of phosphorous tailings to control gobs, the steps are as follows:

[0032] (1) Use the following method to treat phosphorus tailings as general industrial solid waste Class I: the tailings slurry produced by the phosphate rock flotation plant is thickened to a mass concentration of 58% through a thickener, and quicklime or milk of lime is added to the tailings slurry to lower its pH value. Adjust to neutral, thicken to a mass concentration of 55%, and then transport it to the slurry storage tank of the tailings filtration system through pipelines, and then transport it to the filter for primary filtration to obtain a primary filter cake with a moisture content of 13%, which is then transported to the pulping Slurry for pulping, add 5 times the water content of the primary filter cake, stir for 20 minutes, pulp to a concentration of 40%, and then transport to the filter for secondary filtration to obtain a secondary filter cake...

Embodiment 2

[0036] Embodiment 2, a method for harmless filling of phosphorus tailings to treat gobs, the steps are as follows:

[0037](1) Use the following methods to treat phosphorus tailings as general industrial solid waste Class I: the tailings slurry produced by the phosphate rock flotation plant is thickened to a mass concentration of 55% through a thickener, and quicklime or milk of lime is added to the tailings slurry to lower its pH value. Adjust to neutral, thicken to a mass concentration of 55%, and then transport it to the slurry storage tank of the tailings filtration system through pipelines, and then transport it to the filter for primary filtration to obtain a primary filter cake with a moisture content of 13%, which is then transported to the pulping trough for slurry mixing, add clear water 5 times the water content in the primary filter cake, stir for 30 minutes, adjust the slurry to a concentration of 47%, and then transport it to a filter for secondary filtration to o...

Embodiment 3

[0041] Embodiment 3, a method for harmless filling of phosphorous tailings to treat gobs, the steps are as follows:

[0042] (1) Use the following methods to treat phosphorus tailings as general industrial solid waste Class I: the tailings slurry produced by the phosphate rock flotation plant is thickened to a mass concentration of 56% through a thickener, and quicklime or milk of lime is added to the tailings slurry to lower its pH value. Adjust to neutral, thicken to a mass concentration of 53%, and then transport it to the slurry storage tank of the tailings filtration system through pipelines, and then transport it to the filter for a primary filtration to obtain a primary filter cake with a moisture content of 15%, which is then transported to the pulping trough for slurry mixing, add clear water 5 times the water content of the primary filter cake, stir for 25 minutes, adjust the slurry to a concentration of 40%, and then transport it to a filter for secondary filtration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com