Technique of refining solvent in process of producing synthetic rubber

A production process and solvent refining technology, applied in the field of solvent refining technology in synthetic rubber production process, can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

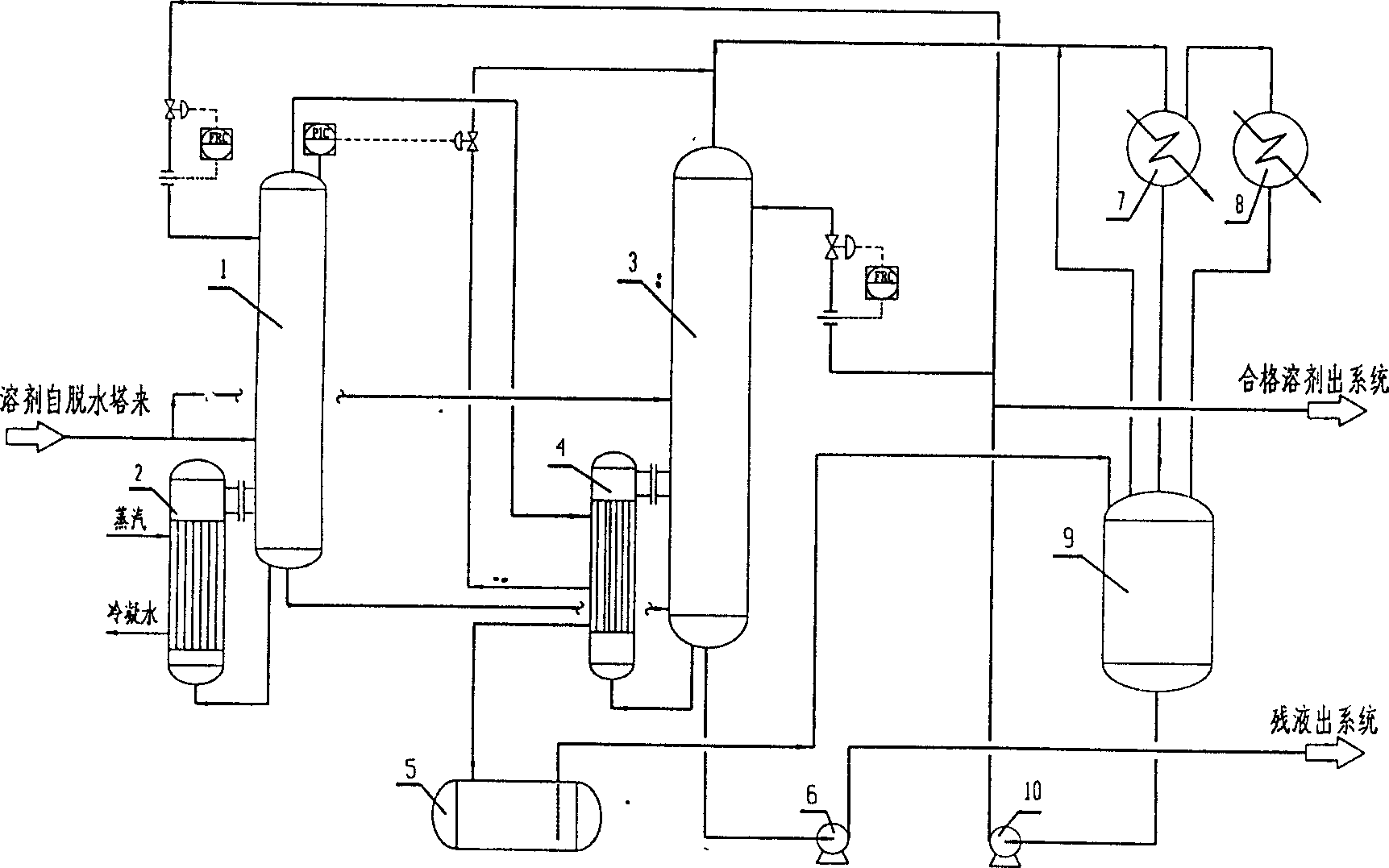

[0026] A two-effect series rectification process for recovering cyclohexane solvent, such as figure 1 As shown, the cyclohexane recovered by the condensation unit enters the dehydration tower of the solvent refining unit to remove water and light components, and is sent to the first-effect rectification tower 1 and the second-effect rectification tower in equal proportions from the dehydration tower tank through the pump. Middle of Tower 3. The operating pressure of the first-effect rectification tower 1 is 0.25MPa (table), the temperature at the top of the tower is 121°C, and the temperature at the bottom of the tower is 128°C. The siphon reboiler 2 is heated by low-pressure steam, and part of the solvent is vaporized in the column tube. Mass transfer separation occurs in the tower, and the solvent with the required purity reaches the shell side of the siphon reboiler 4 of the second-effect rectification tower 3 in gas phase from the top of the first-effect rectification towe...

Embodiment 2

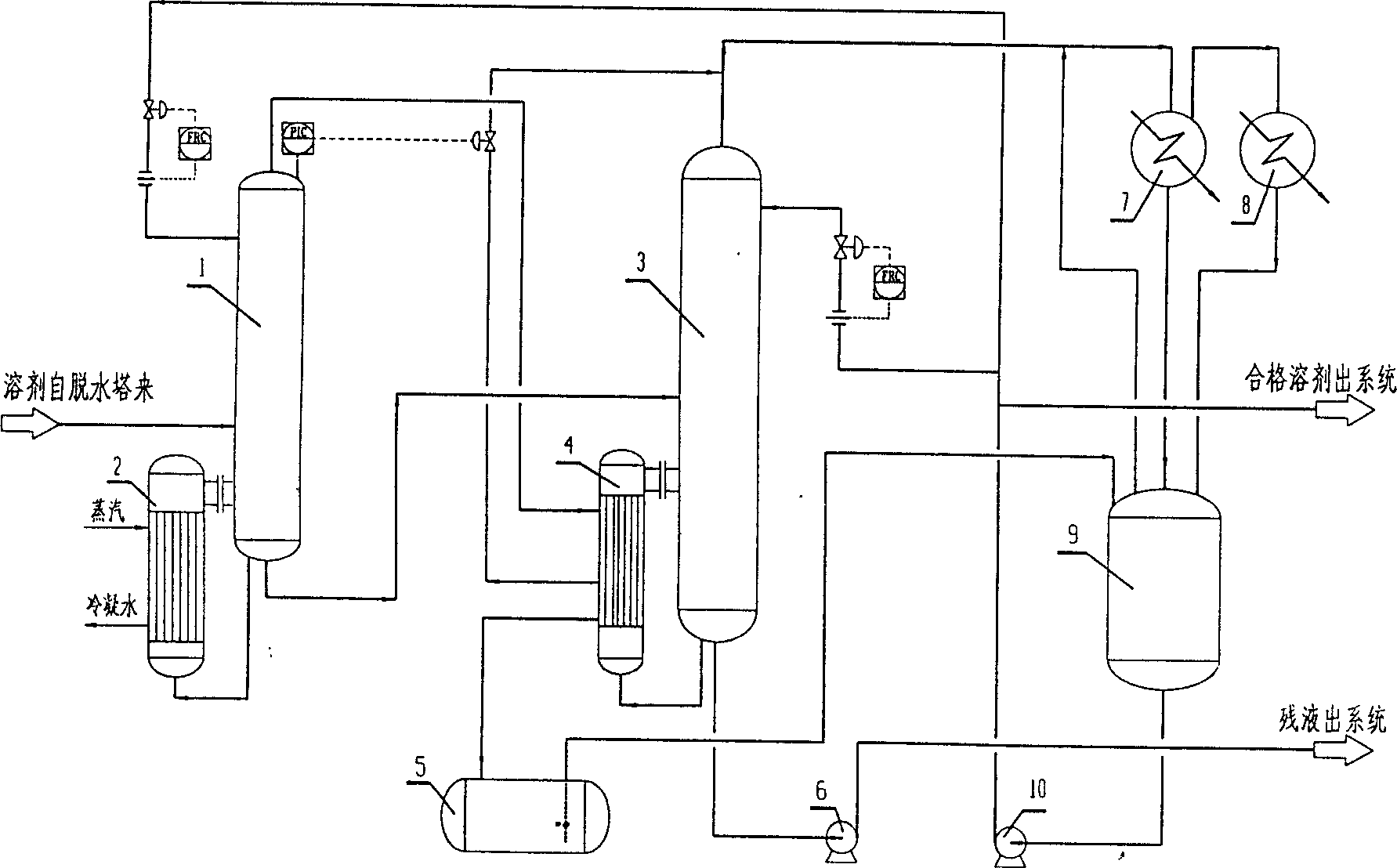

[0031] A two-effect series rectification process for recovering cyclohexane solvent, such as figure 2shown. The cyclohexane recovered by the condensation unit enters the dehydration tower of the solvent refining unit to remove water and light components, and then is pumped to the middle of the first-effect rectification tower 1. The operating pressure of the first-effect rectification tower 1 is 0.25Mpa (table), the temperature at the top of the tower is 121°C, and the temperature at the bottom of the tower is 126°C. The siphon type reboiler 2 is heated by low-pressure steam, and part of the solvent is vaporized in the column tube. Mass transfer separation occurs in the tower, and the solvent with the required purity is discharged from the top of the first-effect tower to the shell side of the siphon reboiler 4 of the second-effect rectification tower 3 in gas phase. The impurity-containing solvent is pressed into the middle part of the second-effect rectification tower 3 fr...

Embodiment 3

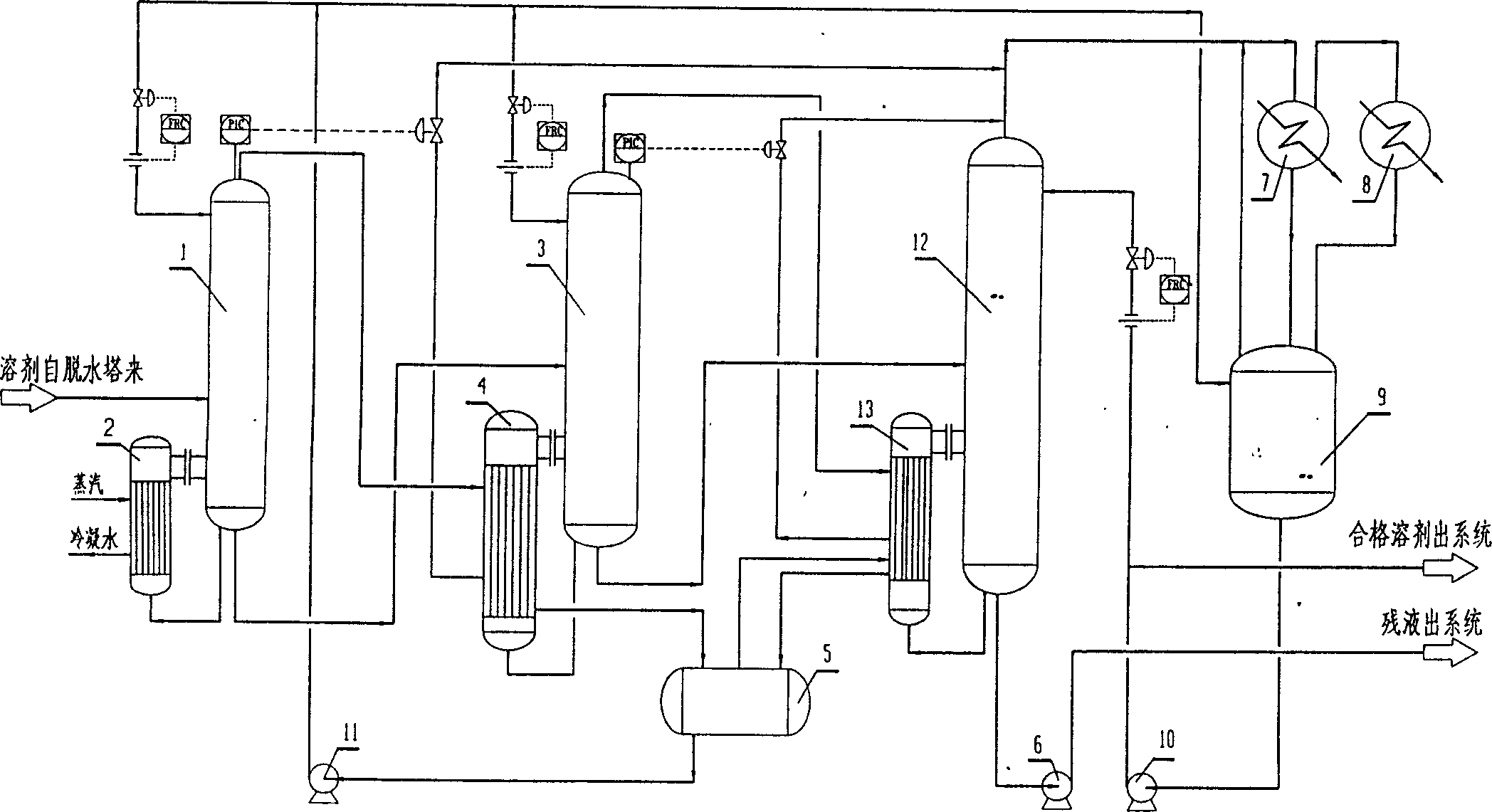

[0036] A three-effect cascade rectification process for recovering cyclohexane solvent, such as image 3 shown.

[0037] After the cyclohexane recovered by the condensation unit enters the dehydration tower of the solvent refining unit for dehydration, it is pumped from the bottom of the dehydration tower to the middle of the first-effect rectification tower 1 . The operating pressure of the first-effect rectification tower 1 is 0.5MPa (table), the temperature at the top of the tower is 140°C, and the temperature at the bottom of the tower is 144°C. The siphon type reboiler 2 is heated by low-pressure steam, and part of the solvent is vaporized in the column tube. Mass transfer separation occurs in the tower, and the solvent with the required purity reaches the shell side of the siphon reboiler 4 of the second-effect rectification tower 3 from the top of the first-effect rectification tower 1 in gas phase. The impurity-containing solvent is pressed into the middle part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com