Low-strength and high-grade road asphalt and preparation method thereof

A road asphalt, high-grade technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of crude oil type dependence, poor anti-aging performance, etc., to improve the use value, improve performance, and improve the poor anti-aging performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 3.84% (referring to the mass ratio of catalytic oil slurry to atmospheric residual oil, the same below) of catalytic oil slurry into atmospheric residual oil obtained by mixing Indonesian Oxi crude oil and Libyan Sirtiga crude oil (3:2). , enter the vacuum distillation column together to obtain vacuum residue.

[0025] Among them, the content of aromatic hydrocarbons in the catalytic oil slurry is more than 50%, and the content of aromatic hydrocarbons in each batch of catalytic oil slurry fluctuates. The catalytic oil slurry of Maoming Branch can be selected, and its aromatic hydrocarbon content is generally above 50%, the same below.

[0026] The inlet temperature of the catalytic oil slurry is 330~350℃, the operating pressure of the vacuum distillation column is 95~100kpa, and the temperature at the bottom of the tower is 360~380℃. Since the vacuum residue required for each tank of asphalt blending generally needs to be continuously processed for 24 hours to meet...

Embodiment 2

[0032] 4.15% of the catalytic oil slurry is added to the atmospheric residual oil obtained by mixing Indonesian Oxi crude oil and Libyan Sirtija crude oil (2:3), and enters the vacuum distillation tower together to obtain vacuum residual oil.

[0033] The content of aromatic hydrocarbons in the catalytic oil slurry is greater than 50%.

[0034] The inlet temperature of the catalytic oil slurry is 330~350℃, the operating pressure of the vacuum distillation column is 95~100kpa, and the temperature at the bottom of the tower is 360~380℃.

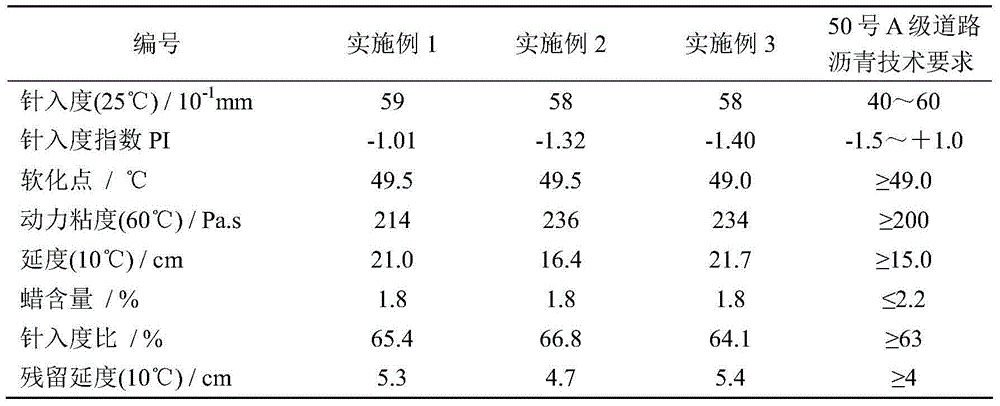

[0035] This vacuum residue is mixed with the vacuum residue obtained by mixing Iranian heavy crude oil - Iran Soluz crude oil (1:1), and the deoiled oil obtained from the vacuum residue of Saudi light crude oil through propane deasphalting process The asphalt was blended in the ratio of 40:38:22 to produce road asphalt. The results are shown in Table 1. This bitumen meets the standards of No. 50 Grade A road asphalt.

[0036] Among them, the ...

Embodiment 3

[0039] 1.0% of the catalytic oil slurry is added to the atmospheric residue obtained by mixing AWB crude oil from Canada and Bairrogan crude oil from Iran (1:1), and enters the vacuum distillation tower together to obtain vacuum residue.

[0040] The content of aromatic hydrocarbons in the catalytic oil slurry is greater than 50%.

[0041] The inlet temperature of the catalytic oil slurry is 330~350℃, the operating pressure of the vacuum distillation column is 95~100kpa, and the temperature at the bottom of the tower is 360~380℃.

[0042] This vacuum residue is blended with the vacuum residue obtained from Saudi medium crude oil and the deoiled asphalt obtained by propane deasphalting process from the vacuum residue of Oman crude oil in a ratio of 74.6:12.8:12.6 to produce road asphalt , and the results are shown in Table 1. This bitumen meets the standards of No. 50 Grade A road asphalt.

[0043] Among them, the vacuum residue obtained from Saudi medium crude oil is an unim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com