Preparation method of rubber plasticizer with low content of polycyclic aromatic hydrocarbons

A technology of rubber plasticizer and cyclic aromatic hydrocarbon, which is applied in the field of preparation of rubber plasticizer with low condensed ring aromatic hydrocarbon content, can solve the problems of difficult quality control, low product yield and high production cost, and achieves low operating cost and high aromatic content. Carbon rate and small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

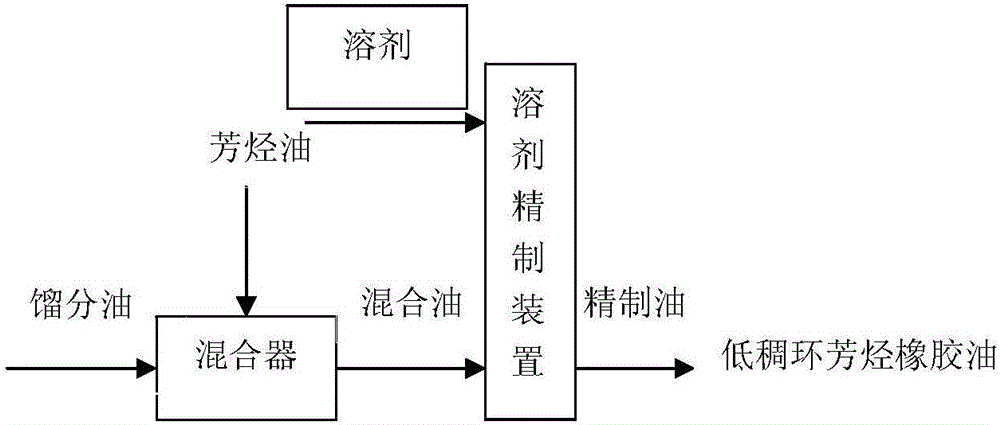

Method used

Image

Examples

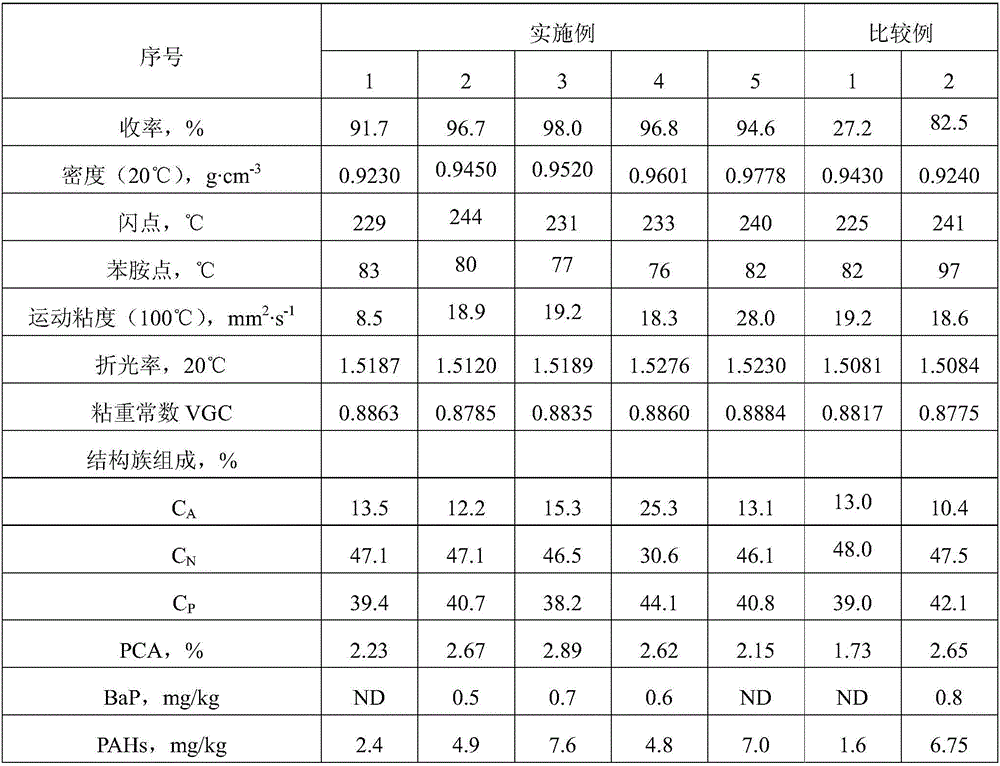

Embodiment 1

[0041] The second-line distillate oil is obtained by vacuum distillation, and the control index is 6-10mm kinematic viscosity at 100°C 2 / s; the reduced second-line distillate oil and aromatic oil are fully mixed in the mixer, and the mixing condition is that the mixed mass ratio of the second-line distillate oil and aromatic oil is 0.5:1; Lift the refined liquid from the top of the tower, the refined liquid is recovered by solvent to obtain refined oil, and the solvent refining temperature is: the temperature at the top of the tower is 80°C, the temperature at the bottom of the tower is 50°C, and the ratio of solvent to oil is 1.8:1.

[0042] In the present embodiment, the physical and chemical parameters of the aromatic oil are:

[0043] Aromatic content is 60%;

[0044] Kinematic viscosity at 100°C is 8mm 2 / s;

[0045] The open flash point is 200°C

[0046] Among them, the content of gum and asphaltene is 0.05%.

Embodiment 2

[0048] The third-line distillate oil is obtained by vacuum distillation, and the control index is 100°C kinematic viscosity is 15-24mm 2 / s; the third-line distillate oil and aromatic oil are fully mixed in the mixer, and the mixing condition is that the mixed mass ratio of the third-line distillate oil and aromatic oil is 2.0:1; Lift the refined liquid from the top of the tower, the refined liquid is recovered by solvent to obtain refined oil, and the solvent refining temperature is: the temperature at the top of the tower is 90°C, the temperature at the bottom of the tower is 60°C, and the ratio of solvent to oil is 1.5:1.

[0049] In the present embodiment, the physical and chemical parameters of the aromatic oil are:

[0050] Aromatic content is 50%;

[0051] Kinematic viscosity at 100°C is 28mm 2 / s;

[0052] The open flash point is 220°C;

[0053] Among them, the content of gum and asphaltene is 0.1%.

Embodiment 3

[0055] The third-line distillate oil is obtained by vacuum distillation, and the control index is 100°C kinematic viscosity is 15-24mm 2 / s; the third-line distillate oil and aromatic oil are fully mixed in the mixer, and the mixing condition is that the mixed mass ratio of the third-line distillate oil and aromatic oil is 3.0:1; Lift the refined liquid from the top of the tower, the refined liquid is recovered by solvent to obtain refined oil, and the solvent refining temperature is: the temperature at the top of the tower is 90°C, the temperature at the bottom of the tower is 60°C, and the ratio of solvent to oil is 1.0:1.

[0056] In the present embodiment, the physical and chemical parameters of the aromatic oil are:

[0057] Aromatic content of 75%;

[0058] Kinematic viscosity at 100°C is 30mm 2 / s;

[0059] The open flash point is 230°C;

[0060] Among them, the content of gum and asphaltene is 0.15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com