Preparation method of environmentally friendly modified coal tar pitch

A coal tar pitch, environment-friendly technology, applied in the processing of tar pitch/petroleum pitch/natural pitch, chemically processing tar pitch/petroleum pitch/natural pitch, petroleum industry, etc. Asphalt oxidation aging and other problems, to achieve the effect of improving performance, low price, simple and easy operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

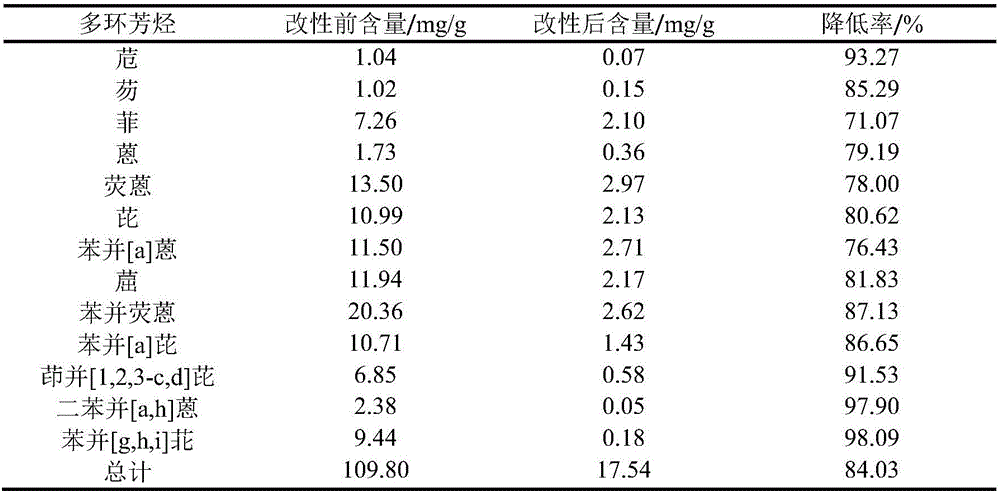

[0022] Mix 5.00 g coal tar pitch and 5% catalyst potassium hydrogen sulfate uniformly, and add 50 mL solvent cyclohexane and 6% modifier 10-undecenal at the same time, and stir and react at 50° C. for 4 hours. The content indexes of polycyclic aromatic hydrocarbons in the modified coal pitch are as follows:

[0023] Table 1

[0024]

Embodiment 2

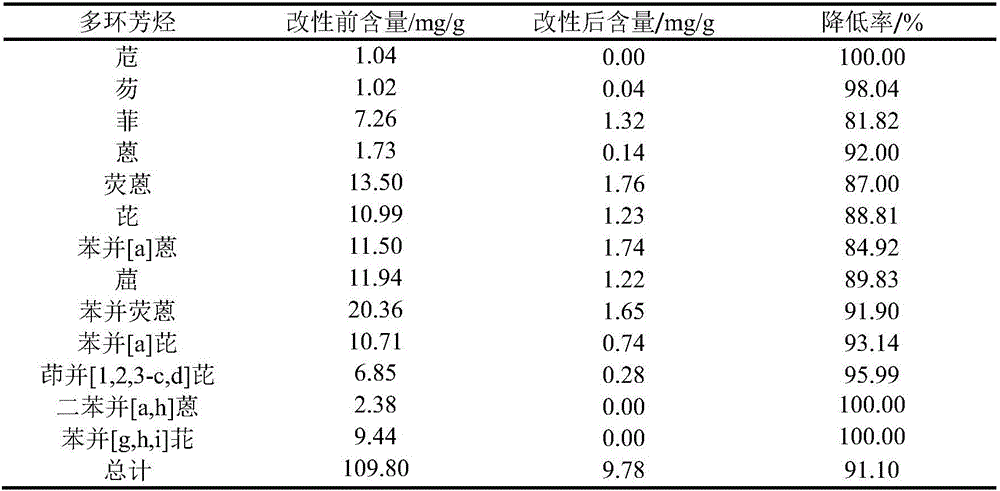

[0026] Mix 5.00 g coal tar pitch and 5% catalyst potassium hydrogen sulfate uniformly, and add 50 mL solvent cyclohexane and 8% modifier 10-undecenal at the same time, and stir and react at 50° C. for 4 hours. The content indexes of polycyclic aromatic hydrocarbons in the modified coal pitch are as follows:

[0027] Table 2

[0028]

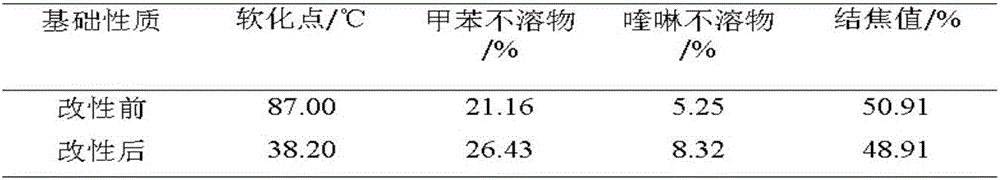

[0029] Refer to the national standards GB / T 4507-1999, GB / T 2292-1997, GB / T 2293-1997, GB / T 8727-2008, the softening point, toluene insoluble matter, quinoline insoluble matter and coking of coal tar pitch before and after modification The values were measured and compared. The specific coal tar pitch softening point, toluene insoluble matter, quinoline insoluble matter, and coking value before and after modification were measured and compared in Table 3.

[0030] table 3

[0031]

Embodiment 3

[0033] Mix 5.00 g coal tar pitch and 5% catalyst potassium hydrogen sulfate uniformly, and add 50 mL solvent cyclohexane and 10% modifier 10-undecenal at the same time, and stir and react at 50° C. for 4 hours. The content indexes of polycyclic aromatic hydrocarbons in the modified coal pitch are as follows:

[0034] Table 4

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com