Transformer oil antigassing additive and preparation method thereof

A transformer oil, anti-gassing technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of difficult operation, high pour point, low target product yield, etc., and achieve monocyclic and bicyclic aromatic hydrocarbons. The effect of high content, low acid value and polycyclic aromatic hydrocarbon content, and excellent anti-gassing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, preparation of transformer oil anti-gassing additive

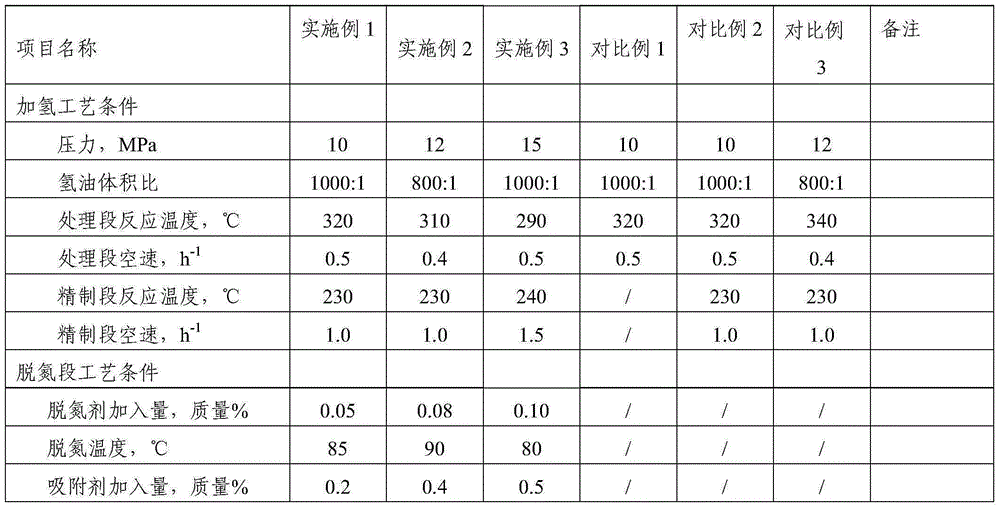

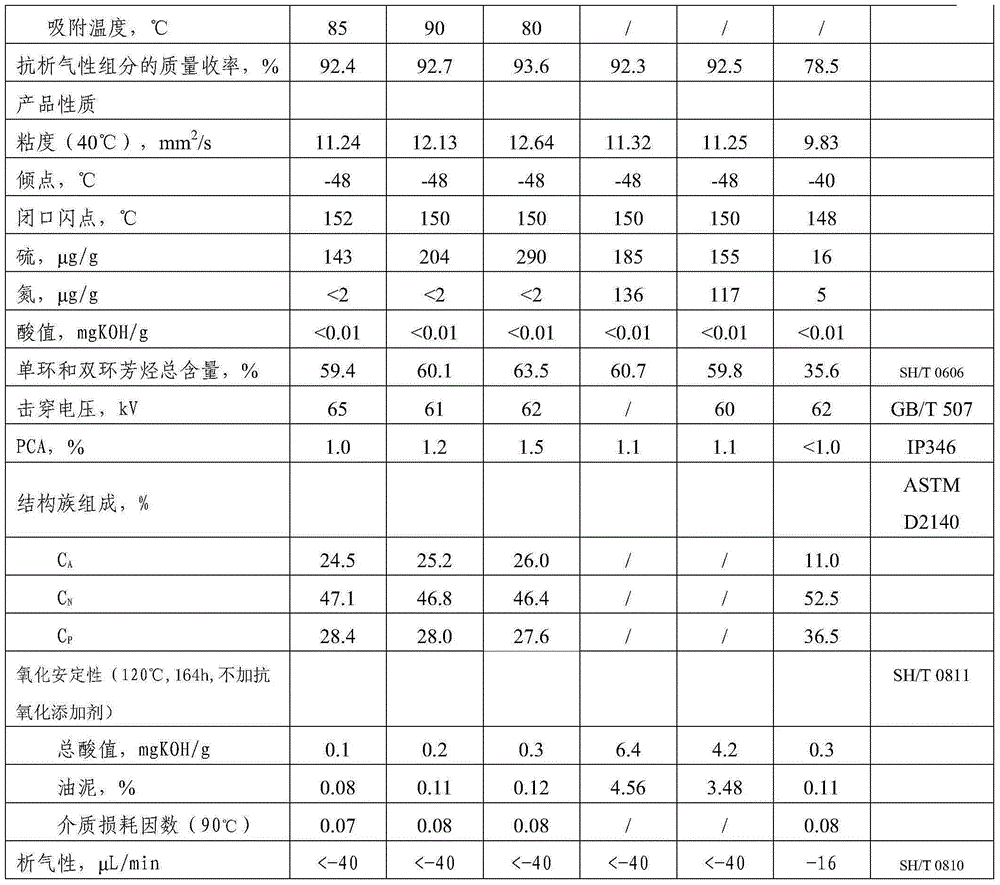

[0027] Using the extract oil refined from transformer oil furfural produced by the industrial plant of China Shipping Asphalt Co., Ltd. as raw material (see Table 1 for detailed properties), the hydrogenation test was carried out in the hydrogenation pilot plant (produced by Beijing Tuochuan Petrochemical Evaluation Equipment Technology Development Co., Ltd., Two reactors are connected in series, the maximum catalyst loading capacity of a single reactor is 200ml, and the new hydrogen is passed once), the first reactor is filled with a hydrogenation treatment catalyst (CH-15), and the second reactor is filled with a hydrogenation make-up Refined catalyst (HJ-14), see Table 2 for detailed operating parameters. Distill the hydrotreated oil, use the distillate above 280°C as the raw material for denitrification, add 0.05% (mass percentage, the same below) of commercially available WSQ-2 denitrification age...

Embodiment 2

[0035] Embodiment 2, preparation of transformer oil anti-gassing additive

[0036] Embodiment 2 is exactly the same as embodiment 1 processing flow, feedstock oil, hydrogenation test device, hydrotreating catalyst, hydrogenation supplementary refining catalyst, denitrification agent are also identical, and adsorbent is light magnesia and alkaline clay (mass Ratio 6:4), specific operating parameters are different from Example 1 (see Table 2 for details).

[0037] It can be seen from the data in Table 2 that the yield of the transformer oil anti-gassing additive relative to the raw material oil is 92.7%, and the content of monocyclic and bicyclic aromatic hydrocarbons in the transformer oil anti-gassing additive is 60.1% (C A Value is 25.2%), gas evolution is less than -40uL / min, sulfur content is 204ug / g, nitrogen content is less than 2ug / g, pour point reaches -48°C, PCA is 1.2%, excellent oxidation stability.

Embodiment 3

[0041] Embodiment 3, preparation of transformer oil anti-gassing additive

[0042] Embodiment 3 is exactly the same as embodiment 1 processing flow, feedstock oil, hydrogenation test device, hydrotreating catalyst, hydrogenation supplementary refining catalyst, denitrification agent are also identical, and adsorbent is light magnesia and alkaline clay (mass Ratio 4:6), specific operating parameters are different from Example 1 (see Table 2 for details).

[0043] It can be seen from the data in Table 2 that the yield of the transformer oil anti-gassing additive relative to the raw material oil is 93.6%, and the content of monocyclic and bicyclic aromatic hydrocarbons in the transformer oil anti-gassing additive is 63.5% (C A Value is 26.7%), gas evolution is less than -40uL / min, sulfur content is 290ug / g, nitrogen content is less than 2ug / g, pour point reaches -48°C, PCA is 1.5%, excellent oxidation stability.

[0044] Table 1 Properties of raw oil

[0045] Analysis ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

| Total acid value | aaaaa | aaaaa |

| Total acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com