Transformer oil anti-gassing additive and preparation method thereof

A transformer oil, anti-gassing technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of high pour point, difficult operation, low yield of target products, etc. The effect of low aromatic content, high mono- and bi-cyclic aromatic content, and excellent gassing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1, preparation of transformer oil anti-gassing additive

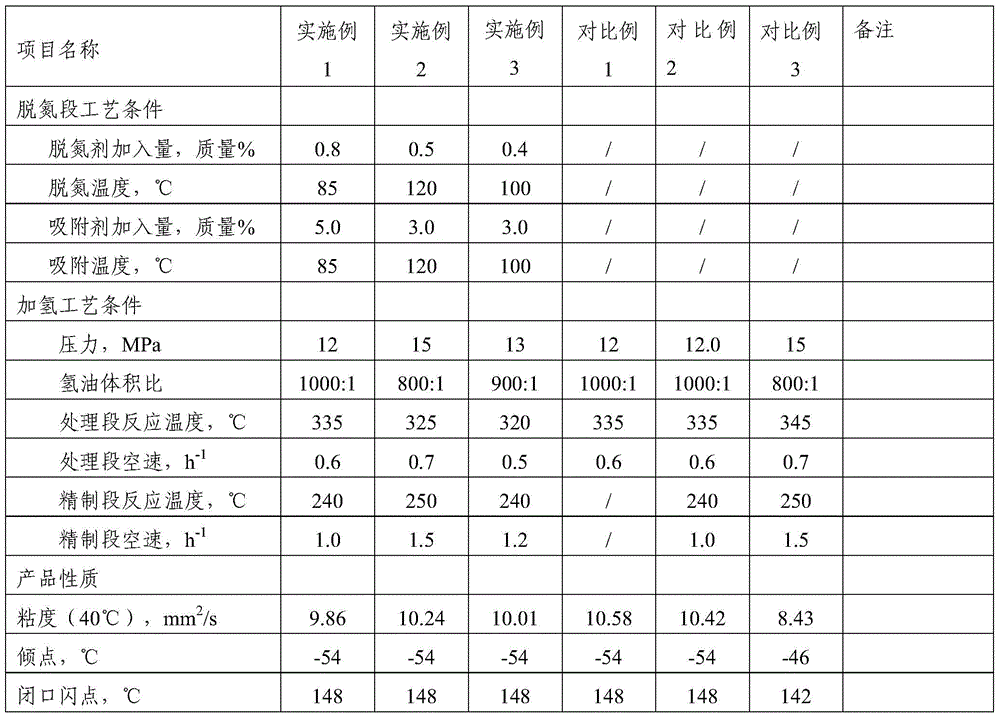

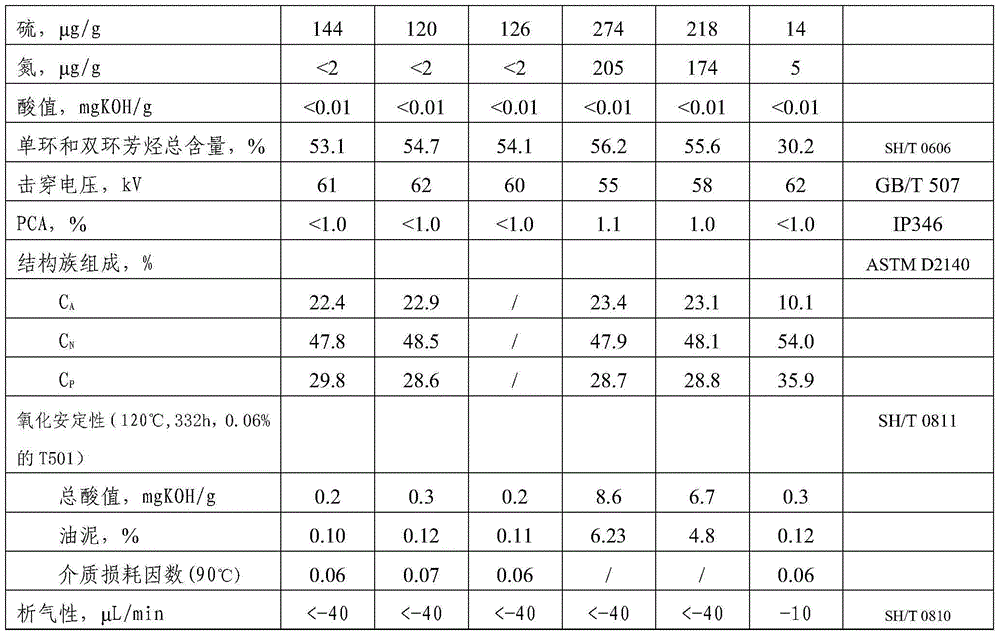

[0026] Using the extracted oil refined from transformer oil furfural produced by the industrial plant of China National Oil and Gas Development and Utilization Company as raw material (see Table 1 for detailed properties), liquid-phase denitrification was carried out in a three-necked glass bottle, and 0.8% of commercially available WSQ-2 denitrification agent was added ( mass percentage, the same below), vigorously stirred, maintained at a temperature of 85° C. for 30 minutes, allowed to stand for separation, and removed residues. The oil phase was continued to be purified by adsorption in a three-neck glass bottle, 5% alkaline clay was added, stirred vigorously, maintained at a temperature of 85°C for 40 minutes, separated by filtration, and the residue was removed to obtain a denitrified refined oil. Using denitrified refined oil as the raw material, the hydrogenation test was carried out in the hydrog...

Embodiment 2

[0034] Embodiment 2, preparation of transformer oil anti-gassing additive

[0035] Example 2 has the same processing flow as Example 1, and the raw oil, hydrogenation test device, hydrotreating catalyst, hydrogenation supplementary refining catalyst, denitrification agent, and adsorbent are also the same, and the specific operating parameters are different from Example 1 (details See Table 2).

[0036] It can be seen from the data in Table 2 that the total content of monocyclic and bicyclic aromatic hydrocarbons in transformer oil anti-gassing additives is 54.7% (C A Value is 22.9%), gas evolution is less than -40uL / min, sulfur content is 120ug / g, nitrogen content is less than 2ug / g, pour point reaches -54°C, PCA is less than 1%, excellent oxidation stability.

Embodiment 3

[0040] Example 3, preparation of transformer oil anti-gassing additive

[0041] Example 3 has the same processing flow as Example 1, and the raw oil, hydrogenation test device, hydrotreating catalyst, hydrogenation supplementary refining catalyst, denitrification agent, and adsorbent are also the same, and the specific operating parameters are different from Example 1 (details See Table 2).

[0042] It can be seen from the data in Table 2 that the total content of monocyclic and bicyclic aromatic hydrocarbons in the anti-gassing additive of transformer oil is 54.1%, the gassing property is less than -40uL / min, the sulfur content is 126ug / g, the nitrogen content is less than 2ug / g, and the pour point reaches -54℃, PCA content is less than 1%, excellent oxidation stability.

[0043] Table 1 Raw Oil Properties

[0044] Analysis Project

Raw oil

Analytical method

Viscosity (40℃), mm 2 / s

14.5

GB / T265

Pour point, °C

-50

GB / T 3535 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com