Combined hydrogenation method for mineral oil and animal and vegetable oil

A technology for animal and vegetable oils and mineral oils, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment. It can solve the problems of affecting catalyst strength and activity stability, affecting device operation cycle, and increasing operating costs. The effect of low operation cycle, equipment investment and operation cost, and low operation pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

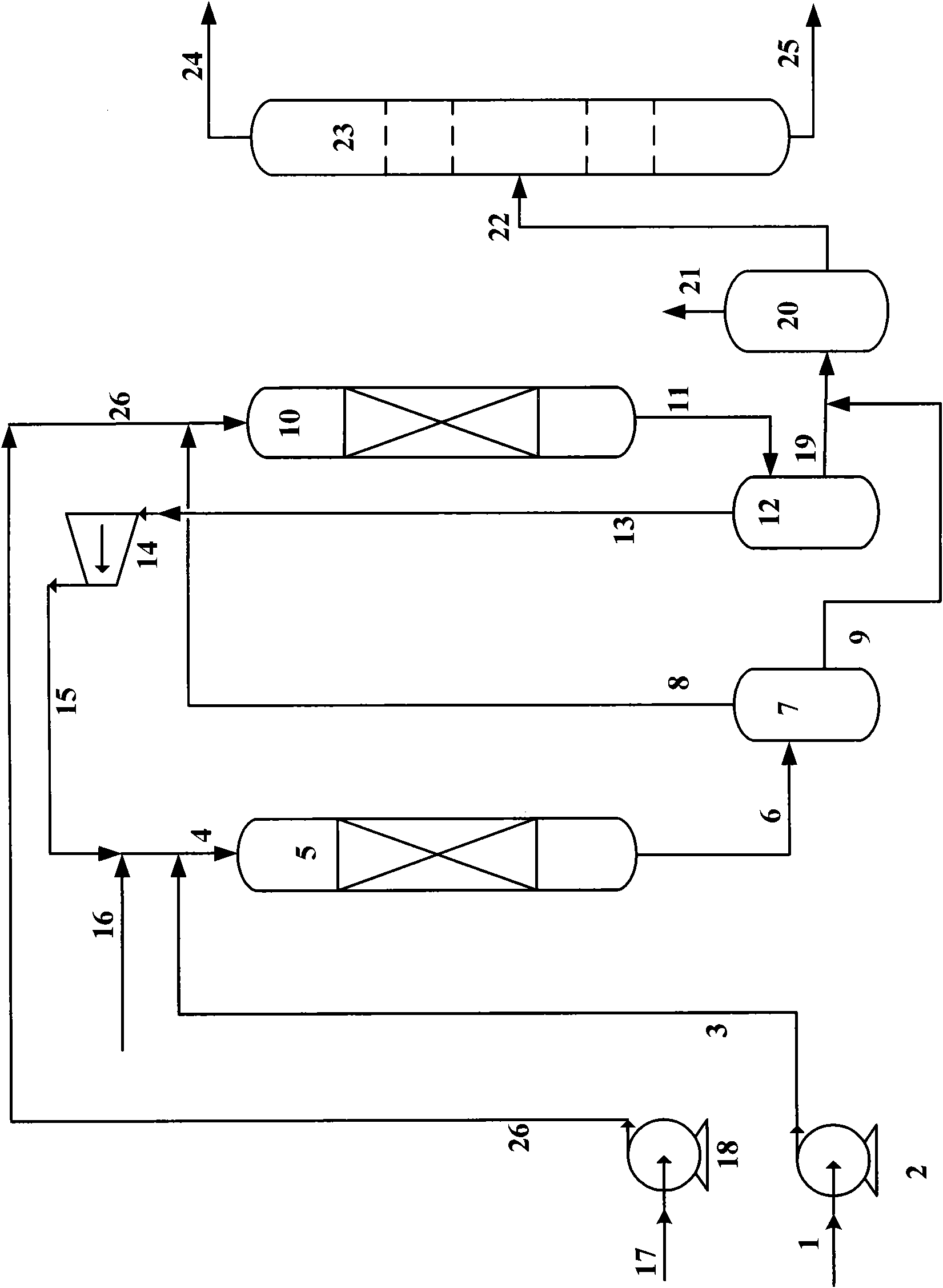

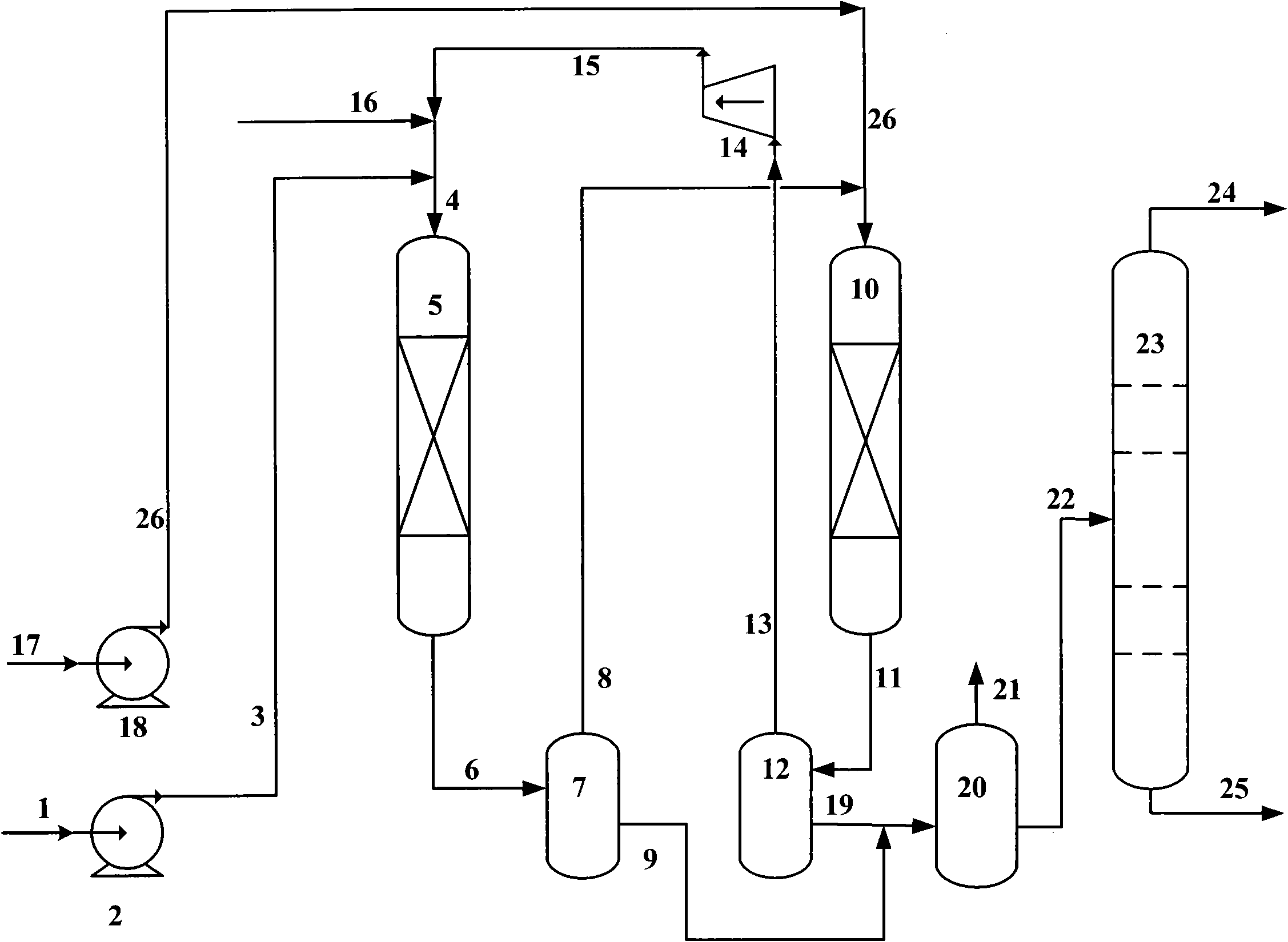

[0019] By the above analysis and understanding of diesel oil cut hydrocarbon composition and cetane number and composition, the specific implementation mode of the present invention is:

[0020] (1) In the first hydrogenation reaction zone, mineral oil with high sulfur content is in the presence of hydrogen, at a reaction temperature of 300-450°C, a hydrogen partial pressure of 2.0-10.0MPa, and a volumetric space velocity of 1.0-6.0h -1 、Hydrogen oil volume ratio 100~800Nm 3 / m 3 Contact with the hydrotreating catalyst to carry out reactions such as hydrodesulfurization, hydrodenitrogenation, olefin saturation and aromatic hydrocarbon saturation, etc., and the reaction effluent is separated to obtain gas phase stream I and liquid phase stream I; gas phase stream I includes hydrogen, hydrogen sulfide , ammonia and a small amount of light hydrocarbons.

[0021] The sulfur content of the mineral oil is 0.2% to 3.0% by weight, and the boiling point range is 40 to 400°C. The pre...

Embodiment 1

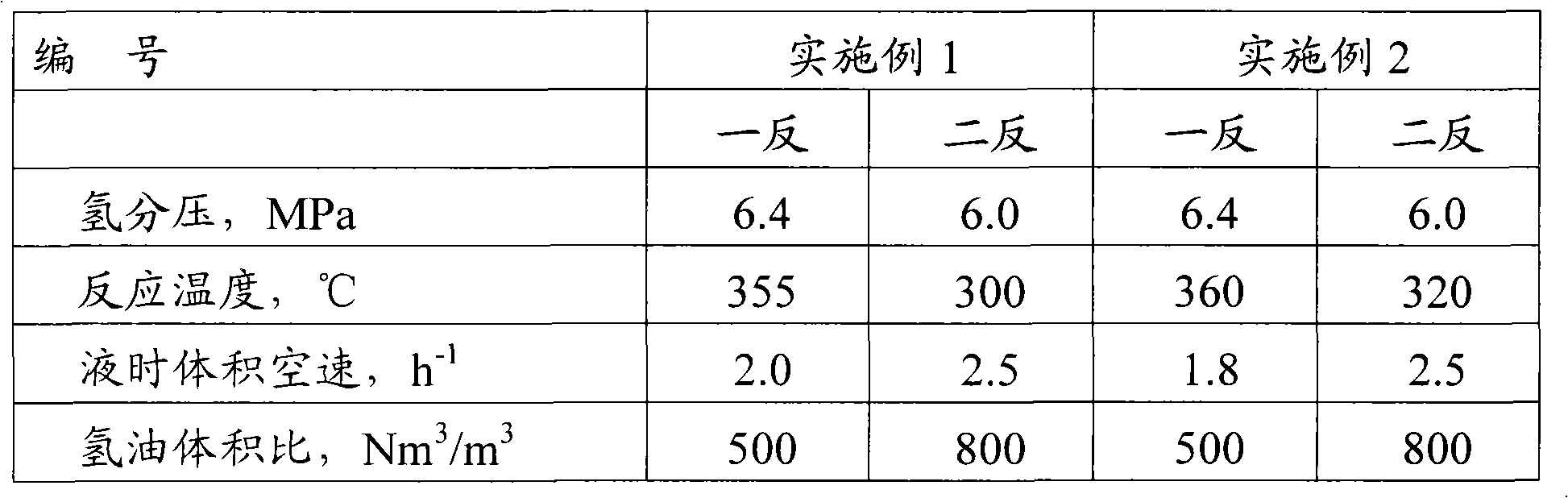

[0049] The raw material oil A is contacted with the hydrofinishing catalyst in the first hydrogenation reactor (one reverse) to react, and the reaction effluent is separated to obtain a gaseous phase stream I and a liquid phase stream I; after the raw material oil B is mixed with the gaseous phase stream I, In the second hydrogenation reactor (second reaction) contact with the hydrotreating catalyst to react, the reaction effluent is separated to obtain the gas phase stream II and the liquid phase stream II; the liquid phase stream I and the liquid phase stream II are mixed and then fractionated system to obtain a diesel product; the gas phase stream II returns to the first hydrogenation reaction zone. The mass ratio of raw material oil A to raw material oil B is 80:20. The concentration of hydrogen sulfide in gas phase stream I was 1.0% by volume. The reaction conditions of this example are shown in Table 2, and the main properties of the diesel product are shown in Table 3....

Embodiment 2

[0051] The raw material oil C is contacted with the hydrofinishing catalyst and the hydrogenation upgrading catalyst in the first hydrogenation reactor (first reverse) to react successively, and the loading volume ratio of the hydrofinishing catalyst and the hydrogenation upgrading catalyst is 70:30; The reaction effluent is separated to obtain a gas phase stream I and a liquid phase stream I; after the raw material oil B is mixed with the gas phase stream I, it is contacted with a hydrogenation protecting agent and a hydrotreating catalyst in the second hydrogenation reactor (second reaction) successively. Reaction, the loading volume ratio of hydrogenation protecting agent and hydrotreating catalyst is 1: 4; Its reaction effluent obtains gaseous phase stream II and liquid phase stream II after separating; Liquid phase stream I and liquid phase stream II mix and go fractionation system to obtain a diesel product; the gas phase stream II returns to the first hydrogenation react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com