Environmental-friendly rubber homogenizing agent and preparation method thereof

An environmentally friendly rubber and leveling agent technology, applied in the field of rubber additives, can solve the problems affecting the unique performance of the leveling agent, high content of carcinogenic polycyclic aromatic hydrocarbons, and insufficient treatment, so as to reduce the carcinogens of polycyclic aromatic hydrocarbons and improve the technical content and added value, energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

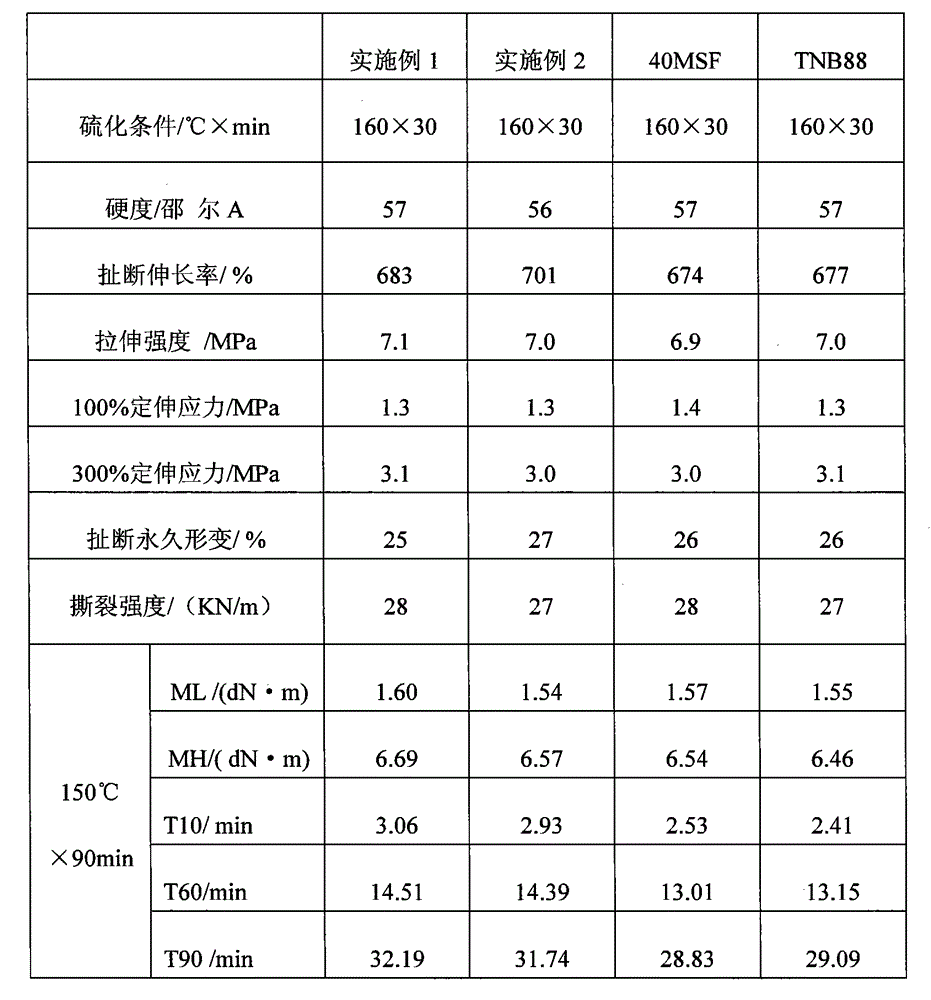

Embodiment 1

[0021] Preparation of modified asphalt: Add 70Kg of road petroleum asphalt and 1.5Kg of phosphoric acid to the reactor, raise the temperature to 255°C, and use an air compressor to blow air with a pressure of 0.2MPa and a flow rate of 2L / (Kg min). Put it into the reaction kettle, and when the softening point of the material reaches 95-100°C, stop blowing in the air, open the vacuum valve, and vacuumize to remove the light components. After the temperature of the material dropped to 160° C., 20 Kg of terephthalic alcohol was added, and the reaction was stirred for 1 hour.

[0022] Preparation of homogeneous agent: Add 70Kg of C5 petroleum resin and 2Kg of p-toluenesulfonic acid into the reaction kettle, heat to melt and stir, add 30Kg of modified asphalt, stir to raise the temperature to 130°C, keep the temperature and stir for 15 minutes to obtain a uniform agent, the measured softening point is 103°C.

Embodiment 2

[0024] A kind of preparation method of environment-friendly rubber leveling agent, concrete steps are as follows:

[0025] Preparation of modified asphalt: Add 90Kg of road petroleum asphalt and 2Kg of phosphoric acid to the reactor, raise the temperature to 265°C, and use an air compressor to blow air with a pressure of 0.4MPa and a flow rate of 2.5L / (Kg min). Put it into the reaction kettle, and when the material reaches the softening point of 90-95°C, stop blowing in the air, open the vacuum valve, and vacuumize to remove the light components. After the temperature of the material dropped to 150° C., 20 Kg of paraformaldehyde was added, and the reaction was stirred for 1 hour.

[0026] Preparation of homogenizer:

[0027] Add 90Kg of C9 petroleum resin and 2Kg of p-toluenesulfonic acid into the reaction kettle, heat to melt and stir, add 20 parts of modified asphalt, stir to raise the temperature to 125°C, keep stirring at the temperature for 15 minutes, and obtain the hom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com