Multistage cross-flow extraction device and method for catalyzing diesel polycyclic aromatic hydrocarbon by using ionic liquid

A technology of ionic liquid and catalytic diesel oil, which is applied in the treatment of hydrocarbon oil, petroleum industry, refined hydrocarbon oil, etc., and can solve the problems of light distillate oil reduction, economic loss, and increase in the load of catalytic devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Common ionic liquids (specifically [BMIM][BF4]) were used as extractants.

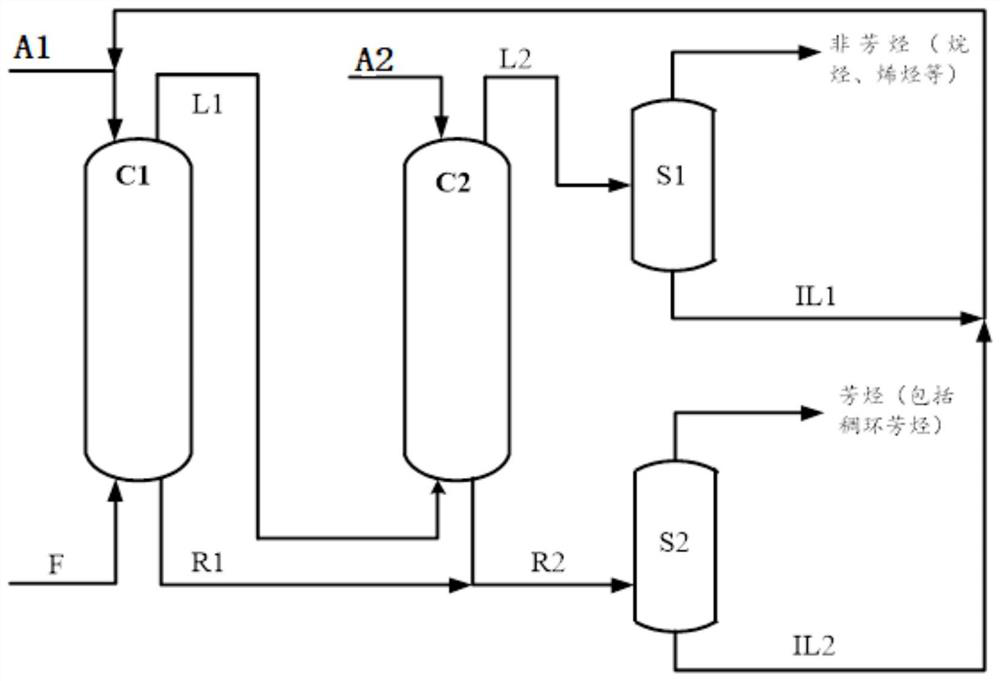

[0036] The feed flow rate is 100kg / h, and the feed contains 70% (mass fraction) of n-hexadecane and 30% (mass fraction) of 1-methylnaphthalene. The feed position of diesel condensed ring aromatic mixture is the bottom of the first-stage extractor (C1), the feed position of common ionic liquid is the top of the first-stage extractor (C1), and the top of the first-stage extractor (C1) takes The output liquid enters the second-stage extractor (C2) from the bottom, and the ordinary ionic liquid enters the second-stage extractor (C2) from the top. The volume ratio of the ordinary ionic liquid to the diesel aromatics to be separated during each stage of extraction is The ratio is 1:1. After multi-stage separation, the recovery rate of n-hexadecane is 99.50%, and the recovery rate of 1-methylnaphthalene is 98.90%. The purity of n-hexadecane in the S1 top extract is 99.8% (mass fraction), and the purit...

Embodiment 2

[0038] A mixed ionic liquid (specifically [BMIM][BF4] and [EMIM][BF4] with a volume ratio of 1:1) was used as the extractant.

[0039] The feed flow rate is 100kg / h, and the feed contains 80% (mass fraction) of n-hexadecane and 20% (mass fraction) of 1-methylnaphthalene. The feed position of the diesel aromatics mixture is the bottom of the first-stage extractor (C1), the feed position of the mixed ionic liquid is the top of the first-stage extractor (C1), and the output liquid from the top of the first-stage extractor (C1) Enter the second-stage extractor (C2) from the bottom, and the ionic liquid enters the second-stage extractor (C2) from the top. The volume ratio of the ionic liquid to the diesel aromatics to be separated during each stage of extraction is 1:1. , the recovery rate of n-hexadecane after multistage separation is 99.60%, and the recovery rate of 1-methylnaphthalene is 99.10%. The purity of n-hexadecane in the S1 top extract is 99.8% (mass fraction), and the ...

Embodiment 3

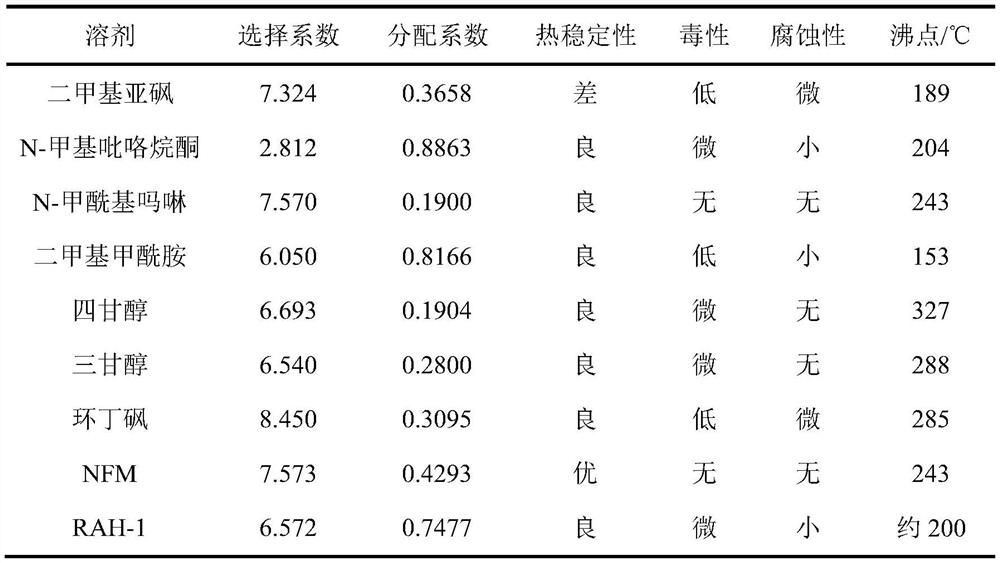

[0041] A mixed solution of common ionic liquid (specifically [BMIM][BF4]) + organic solvent (specifically sulfolane) (the volume ratio of ionic liquid to organic solvent is 3:7) was used as the extraction agent.

[0042] The feed flow rate is 100kg / h, and the feed contains 75% (mass fraction) of n-hexadecane and 25% (mass fraction) of 1-methylnaphthalene. The feed position of the diesel aromatic mixture is the bottom of the first-stage extractor (C1), the feed position of the mixed extractant is the top of the first-stage extractor (C1), and the production liquid at the top of the first-stage extractor (C1) Enter the second-stage extractor (C2) from the bottom, and the mixed extractant enters the second-stage extractor (C2) from the top, and the volume ratio of the mixed extractant and the diesel aromatic hydrocarbon to be separated during each stage of extraction is 2 : 1, the recovery rate of n-hexadecane after multistage separation is 99.8%, and the recovery rate of 1-methy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com