Process for reducing content of sulphur compounds and poly-aromatic hydrocarbons in a hydrocarbon feed

a technology of polyaromatic hydrocarbons and hydrocarbon feeds, which is applied in the direction of physical/chemical process catalysts, metal/metal-oxide/metal-hydroxide catalysts, fuels, etc., can solve the problems of increasing the catalyst's coke-making propensity, reducing the yield of valuable products, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

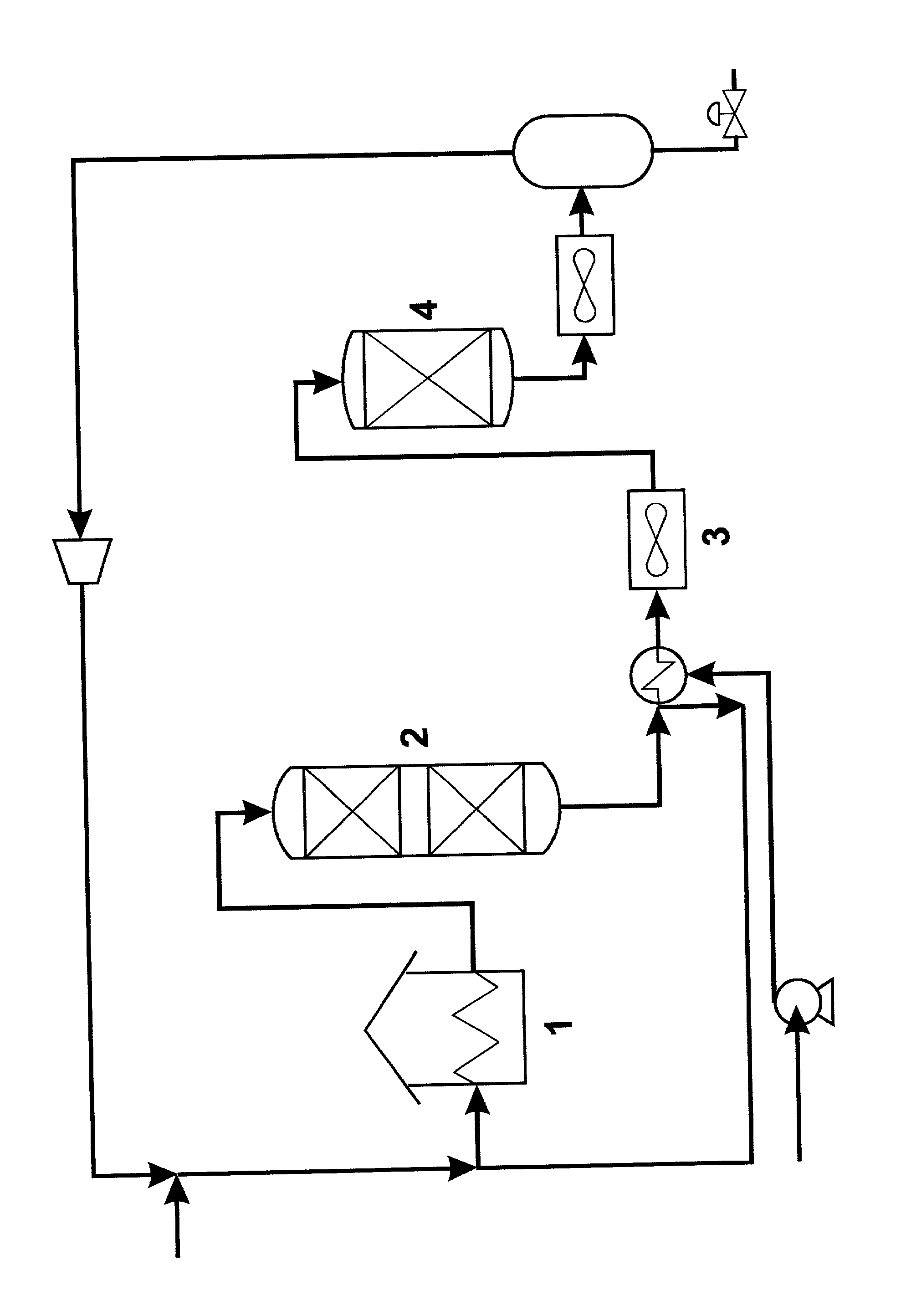

Method used

Image

Examples

example 2

[0035] Product A from Example 1 is further hydrotreated at lower temperatures at high LHSV. The pressure is 50 bar, which is identical to the pressure at which product A was obtained.

[0036] A Ni--Mo on alumina catalyst is used in this test. The results are shown in Table 3.

3TABLE 3 Properties of products in Example 2: Temp-era-N Di-aro- Tri-ture LHSV SG S (wt matics aro- PAH (.degree. C.) (h.sup.-1) 60 / 60 (wt %) ppm) (wt %) matics (wt %) 325 6 0.8914 0.0038 505 4.6 5.0 9.6 350 6 0.8911 0.0029 468 4.9 4.9 9.5

[0037] As illustrated from the Table 3 there are a remarkable sulphur and nitrogen removal in this low temperature hydrotreatment, and further it is quite obvious that a large amount of the PAH can be removed at a relatively high LHSV during this low temperature posttreatment. Both the sulphur removal and the PAH removal is due to the shift in equilibrium.

example 3

[0038] Product B from Example 1 is further hydrotreated at lower temperatures at different LHSV and temperatures. The pressure is 50 bar, which is identical to the pressure at which product B was obtained. A Ni--Mo on alumina catalyst is also used in this test. The results are shown in Table 4.

4TABLE 4 Properties of products in Example 3: Tem- Tri-pera-N Di-aro- aro-ture LHSV SG S (wt matics matics PAH (.degree. C.) (h.sup.-1) 60 / 60 (wt %) ppm) (wt %) (wt %) (wt %) 300 2 0,9369 0,1500 2058 7,7 20,1 27,8 300 4 0,9390 0,1588 2067 10,2 21,3 31,5 300 6 0,9406 0,1618 2080 9,9 21,4 31,6 350 2 0,9335 0,1049 1657 6,6 17,0 23,6 350 4 0,9365 0,1317 1870 9,2 18,1 27,3 350 6 0,9378 0,1442 1877 9,6 19,3 28,9

[0039] Again it is clear that a large amount of the poly-aromatic compounds can be removed at low temperature (and the same pressure) due to the shift in equilibrium. Again there is a significant and important sulphur removal at this low-temperature hydrotreatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| outlet temperature | aaaaa | aaaaa |

| outlet temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com