Preparation method and application of graphite-phase carbon nitride-based heterogeneous Fenton-like catalyst

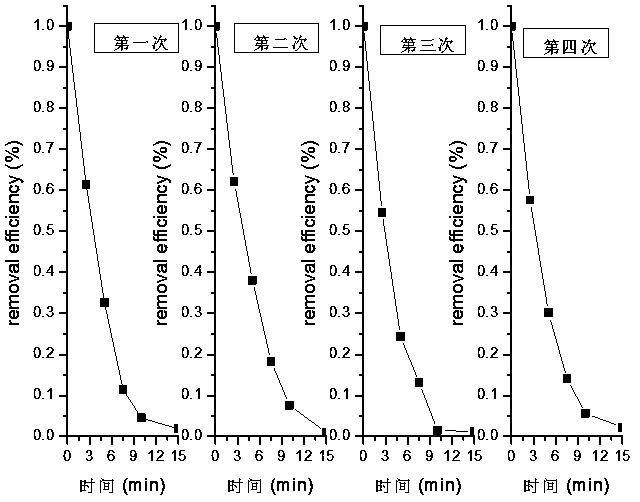

A phase carbon nitride-based, catalyst technology, used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as product instability and complex production, and achieve a wide range of pH application and repeatability. High utilization rate and stable treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

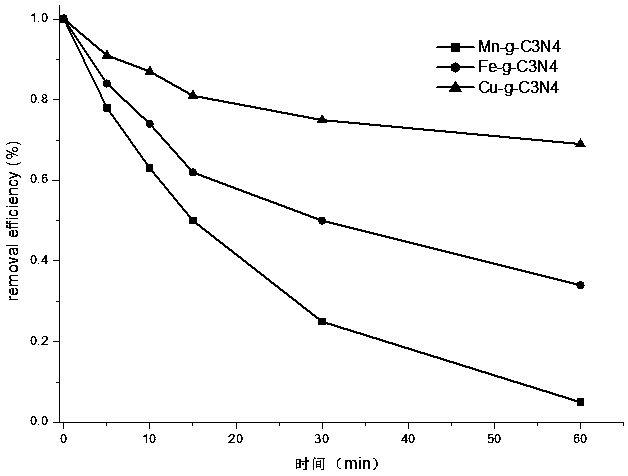

[0026] Example 1: Manganese doped g-C 3 N 4 Catalytic degradation of ACT by heterogeneous catalyst

[0027](1) Weigh and mix the corresponding substances according to the ratio of 0.5mmol manganese dichloride + 6g urea;

[0028] (2) Add the above mixture into a 50ml ceramic crucible, wrap the mouth of the pot with aluminum foil, cover it and put it into a muffle furnace for calcination. First raise the temperature to 133°C at 20°C / min, stay for 10 minutes, then raise the temperature to 500°C at 20°C, and then keep the temperature at 500°C for 2.5h;

[0029] (3) After the calcination is completed, cool naturally to room temperature, take out and grind to obtain manganese-doped g-C 3 N 4 composite material.

[0030] (4) The Mn-g-C prepared above 3 N 4 The composite material was added to ACT wastewater with an initial pH of 6.5, in which the concentration of PMS was 0.6g / L, the concentration of ACT was 20mg / L, the dosage of the material was 50mg / L, and the stirring rate wa...

Embodiment 2

[0031] Example 2: Iron-doped g-C 3 N 4 Catalytic degradation of ACT by heterogeneous catalyst

[0032] Preparation of Fe-g-C with Ferric Chloride as Precursor 3 N 4 Composite materials, according to the ratio of 0.5mmol ferric chloride + 6g urea to weigh the corresponding substances, other conditions are the same as in Example 1. Its 60min removal rate of ACT was 76%.

Embodiment 3

[0033] Example 3: Catalytic degradation of ACT by copper-doped g-C3N4 heterogeneous catalyst

[0034] Preparation of Cu-g-C with copper dichloride as precursor 3 N 4 Composite materials, according to the ratio of 0.5mmol copper dichloride + 6g urea to weigh the corresponding substances, other conditions are the same as in Example 1. Its 60min removal rate of ACT was 31%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com