Method for preparing non-toxic visible ultraviolet heat insulating UV coating material

A technology for food packaging and coatings, which is applied in the field of packaging composite materials and photocuring. It can solve the problems of easy oxidation and deterioration of fatty acids, short wavelength of ultraviolet light, and weak penetrating power, and achieve the effects of reducing deterioration waste, obvious environmental benefits, and extending shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Coupling treatment of silica:

[0024] Add 0.2%-1% of the mass of silane coupling agent or titanate coupling agent to the purchased white carbon black prepared by meteorological method, add appropriate amount of ethanol for wetting, and perform grinding and dispersing surface modification treatment.

Embodiment 2

[0026] Preparation of metal-doped tin dioxide nanopowder:

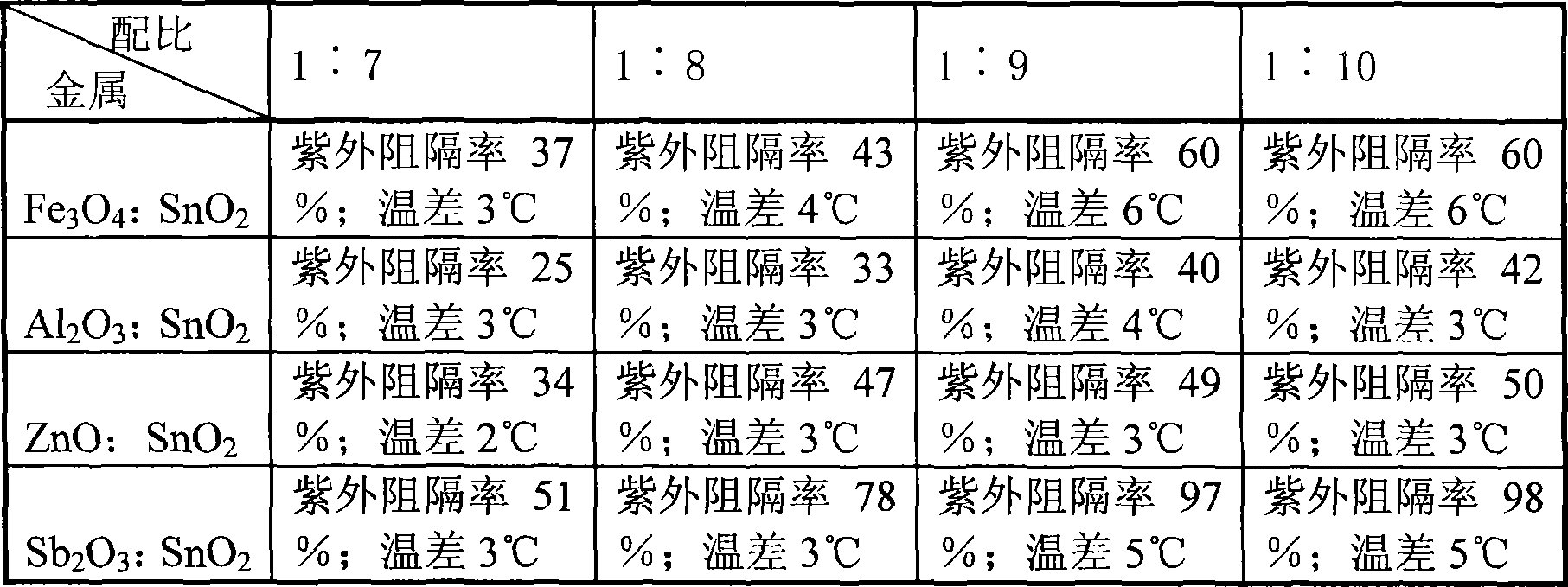

[0027] Metal-doped tin dioxide nanopowders were prepared by solid-phase synthesis: Fe was weighed in a certain molar ratio 3 o 4 and SnO 2 、Al 2 o 3 and SnO 2 , ZnO and SnO 2 , Sb 2 o 3 and SnO 2 , adding an appropriate amount of acetone to disperse, ball mill, dry, and calcined at 600-1100°C to obtain powders ranging from light blue to dark blue.

[0028] Preparation of metal-doped tin dioxide nanopowder by liquid phase co-precipitation method: Fe 3 o 4 and SnO 2 、Al 2 o 3 and SnO 2 , ZnO and SnO 2 , Sb 2 o 3 and SnO 2 , dissolved in HCl, and neutralized with ammonia as a precipitating agent to obtain a precipitate. The precipitate is washed, suction filtered, dried, and calcined at 850°C to obtain nanometer powder.

[0029] Preparation of metal-doped tin dioxide nanopowders by combustion method: Weigh Fe respectively according to a certain molar ratio 3 o 4 and SnO 2 、Al 2 o 3 and SnO 2 , Z...

Embodiment 3

[0035] A kind of non-toxic visible UV insulation UV coating for food packaging, by weight percentage: 25% of polyurethane acrylate oligomer, 20% of epoxy acrylate oligomer, 20% of tripropylene glycol diacrylate, three Methylol propane triacrylate 12%, 1,6-hexanediol diacrylate 9%, white carbon black 3%, using Sb 2 o 3 :SnO 2 1:9 metal-doped tin dioxide nanopowder 5%, 1-hydroxy-cyclohexyl acetophenone 4.5%, wetting and dispersing agent 0.4%, anti-settling agent 0.6%, leveling agent 0.3%, disinfectant Formulated with 0.2% foaming agent. The preparation method is the same as above. The UV blocking rate of the obtained paint after film coating is 97%, and the temperature difference is 5°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com