Colored alkali aluminosilicate glass articles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

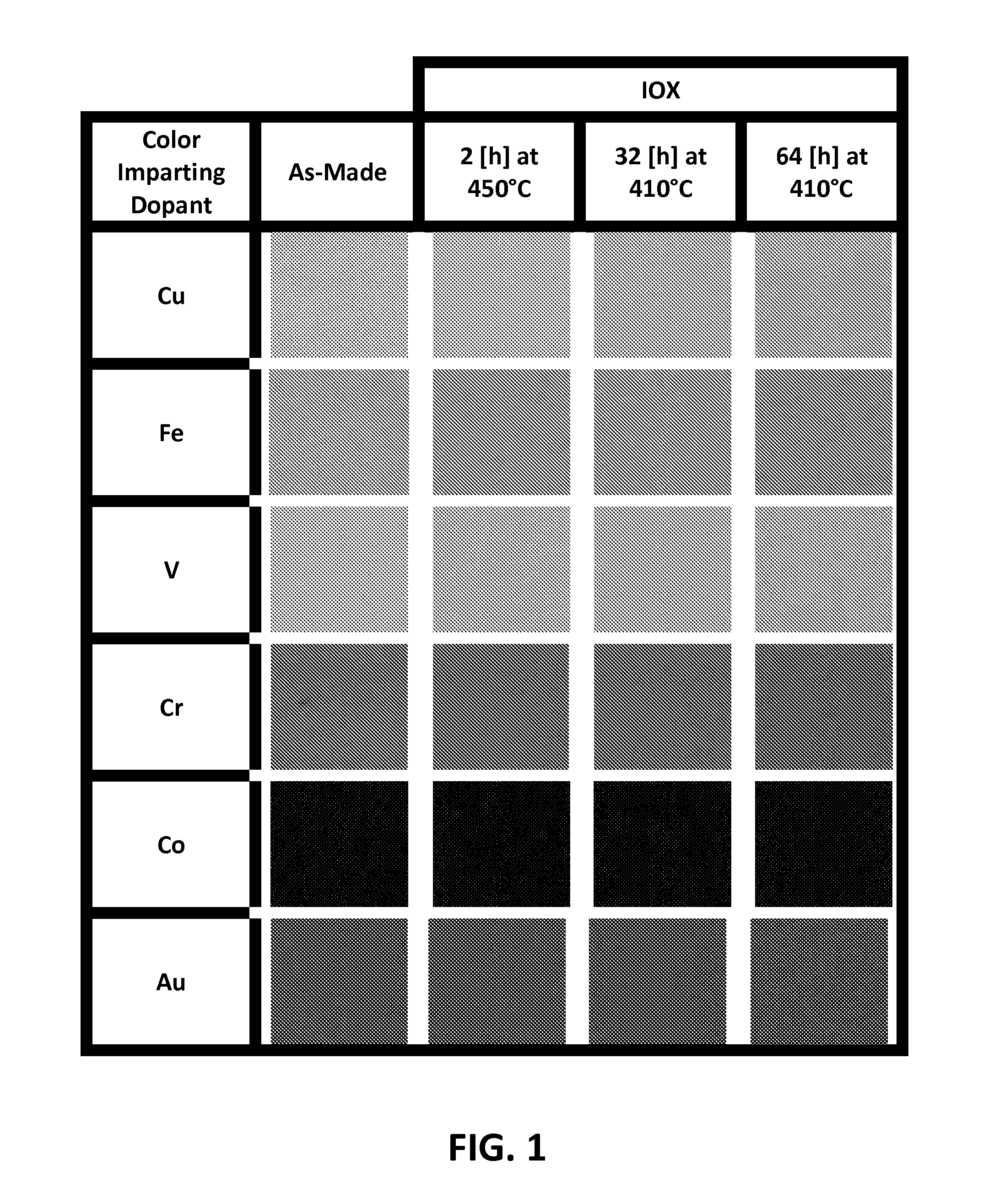

Example Glasses A-F

[0087]Example glasses A-F described in the following were batched with Si as sand, Al as alumina, Na as both soda ash and sodium nitrate, B as boric acid, and P as aluminum metaphosphate. For example glasses A-F, six distinct compositions were formulated so that each had a different colorant including one or more metal containing dopants formulated to impart a different preselected color added to the batch with iron (Fe) added as Fe2O3, vanadium (V) added as V2O5, chromium (Cr) added as Cr2O3, cobalt (Co) added as Co3O4, copper (Cu) added as CuO, and gold (Au) added as Au. The batch materials were melted at 1600° C. for four hours and then poured and annealed between 550° C. and 650° C. The compositions of example glasses A-F were analyzed by inductively coupled plasma and / or atomic absorption and / or X-ray fluorescence (XRF) techniques to determine the mol % of the constituent materials in each. The specific compositions for each of example glasses A-F are reporte...

example glass

G

[0106]For Example glass G described in the following, 25 distinct batches were prepared with Si as sand, Al as alumina, Na as both soda ash and sodium nitrate, B as boric acid, and P as aluminum metaphosphate. Each of the 25 distinct batches of example glass G was formulated without metal containing dopants. Each of the 25 distinct batches was melted at 1600° C. for four hours and then poured and annealed between 550° C. and 650° C. The composition each example glass G corresponding one of the 25 distinct batches was analyzed by inductively coupled plasma and / or atomic absorption and / or X-ray fluorescence (XRF) techniques to determine the mol % of the constituent materials in each. The range of compositions of example glass G is reported in Table XI.

TABLE XIExample Glass G Composition in Mole Percent [Mol %]SiO2Al2O3Na2OK2OMgOCaOSnO2ZrO2Fe2O3Range68.07.012.00.15.00.00.10.00.071.09.515.02.07.41.00.20.00.0

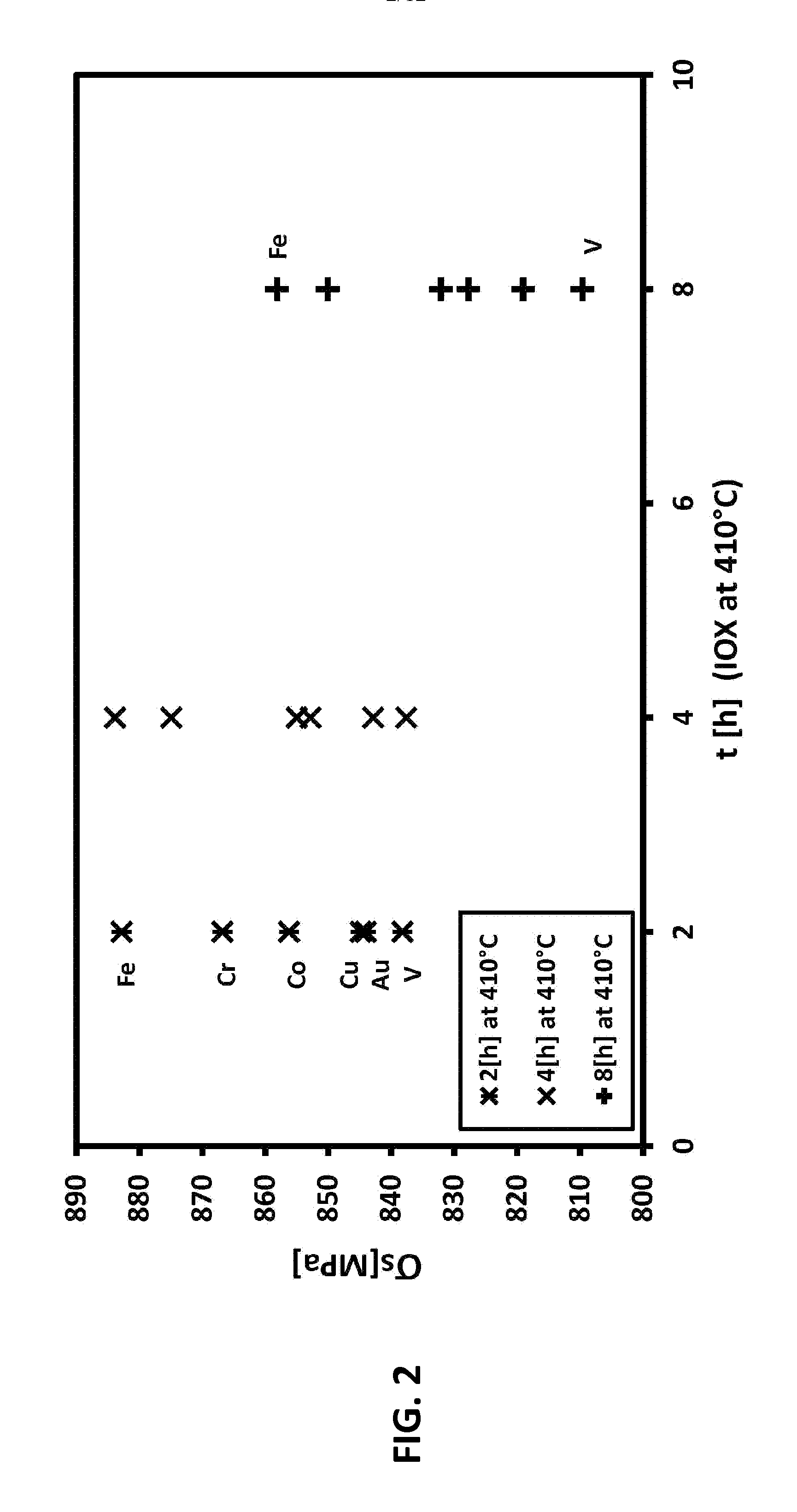

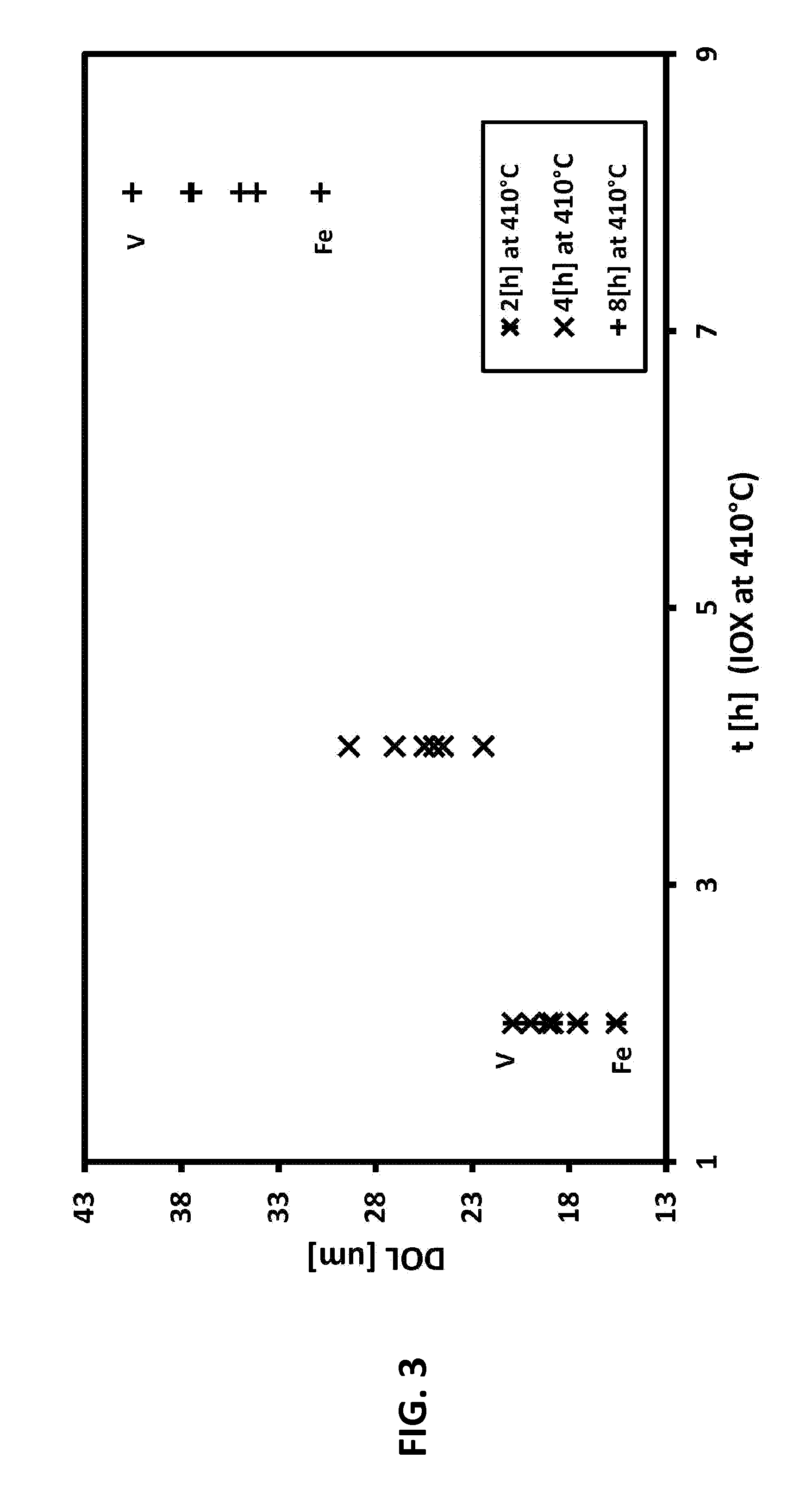

Samples 37-61

[0107]For each bath of example glass G, as-made substrates were co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| depth of layer | aaaaa | aaaaa |

| mol % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com