Multi element daged-anatase type TiO2 collosol photo catalyst and its preparation method

An anatase type, photocatalyst technology, used in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of low particle crystallinity, unreachable photoactivity, low visible light activity, etc. problems, to achieve the effect of saving investment, high industrial output rate and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

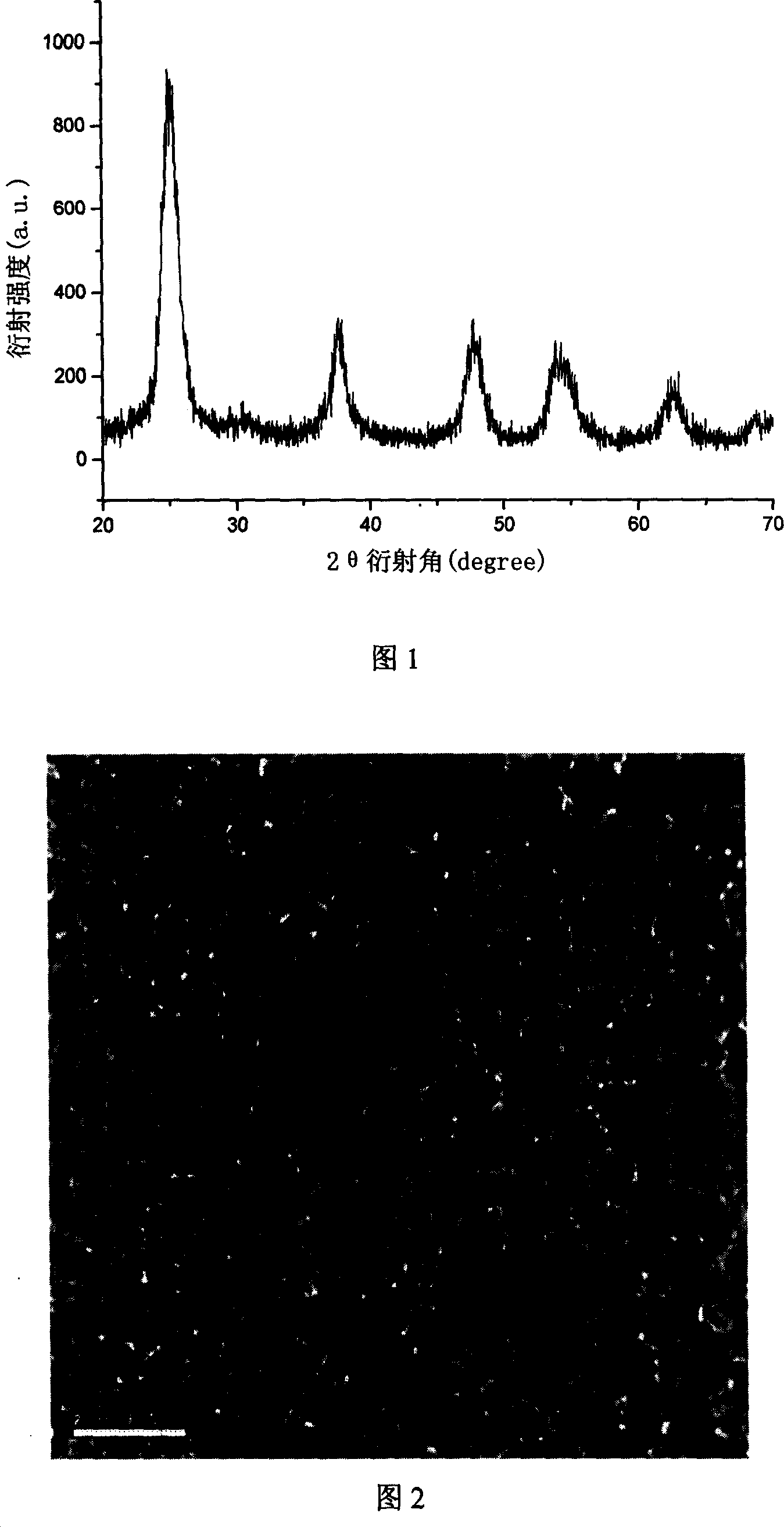

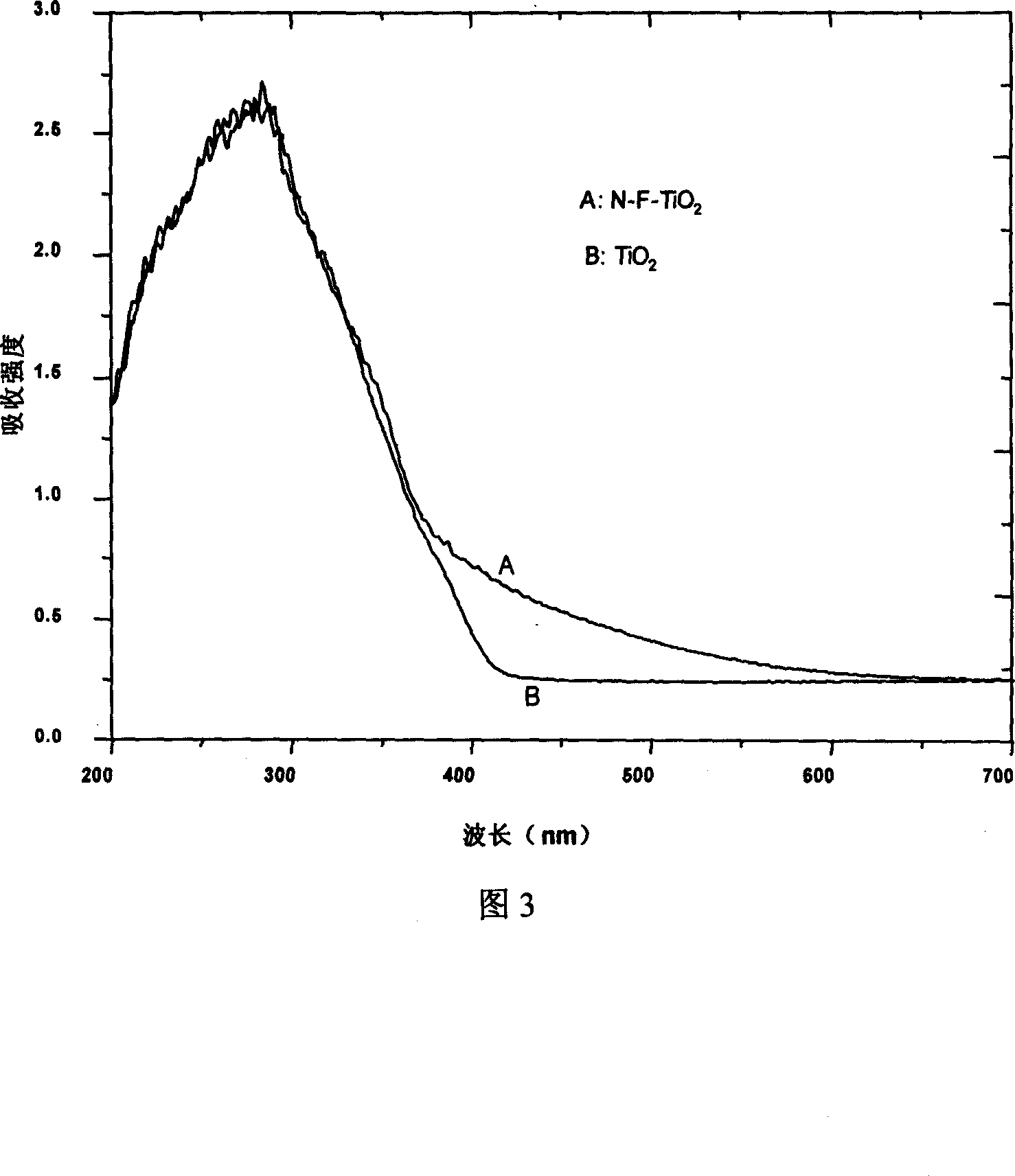

[0036] 14mL TiCl 4 Add 50mL of deionized water at 0°C, adjust the pH to 8-9 with dilute ammonia water, and produce a white precipitate. Filter and wash with deionized water until the filtrate is detected by silver nitrate and no silver chloride precipitate appears. Under the condition of stirring, add 200mL distilled water to the precipitation to obtain a titanium dioxide slurry, and adjust the pH to 1-2 with a concentration of 40% nitric acid to obtain transparent TiO 2 Aqueous sol; hydrofluoric acid is added to the sol so that the atomic ratio of F to Ti is 1:10, and the hydrothermal reaction is carried out at 80°C for 20 hours in a reactor to obtain transparent fluorine-doped anatase TiO 2 Sol. After testing, its crystallinity is 55%, and the mass content of titanium dioxide is about 5%. The sol has high stability and can maintain uniform dispersion for a long time (more than half a year) without stratification and precipitation.

[0037] Gained sol is added in the solut...

Embodiment 2

[0039] 14mL TiCl4 Add 50mL of deionized water at 0°C, adjust the pH to 8-9 with dilute ammonia water, and produce a white precipitate. Filter and wash with deionized water until the filtrate is detected by silver nitrate and no silver chloride precipitate appears. Add 100mL distilled water to the precipitation to obtain a titanium dioxide slurry, adjust the pH to 1-2 with 40% nitric acid, and degelize to obtain transparent TiO 2 Water sol; triethylamine is added to the sol so that N / Ti (atomic ratio) = 0.07, in a reaction kettle, 200 ° C hydrothermal reaction for 6 hours, to obtain transparent nitrogen-doped anatase TiO 2 The sol has a crystallinity of 37%, and the mass content of titanium dioxide is about 10%.

[0040] The catalytic activity evaluation conditions were the same as in Example 1, the solution was irradiated with a light source for 6 hours, and the degradation rate of Rhodamine B by the sol was 63% (see Table 1).

Embodiment 3

[0042] 14mL TiCl 4 Add 50mL of deionized water at 0°C, adjust the pH to 8-9 with dilute ammonia water, and produce a white precipitate. Filter and wash with deionized water until the filtrate is detected by silver nitrate and no silver chloride precipitate appears. Add 1L of distilled water to the precipitation to obtain a titanium dioxide slurry, adjust the pH to 1-2 with 40% nitric acid, and degelize to obtain transparent TiO 2 Water sol; add hydrofluoric acid and triethylamine to the sol at the same time, so that F / Ti=0.03, N / Ti=0.1 (atomic ratio), in a reaction kettle, 130 ° C hydrothermal reaction for 12 hours, to obtain transparent nitrogen doped anatase TiO 2 The sol has a crystallinity of 59%, and the mass content of titanium dioxide is about 1%.

[0043] The catalytic activity evaluation conditions are the same as those in Example 1. The solution was irradiated with a light source for 6 hours, and the degradation rate of Rhodamine B by the sol was 81% (see Table 1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com