Preparation method of red overglaze color Ce:YAG fluorescent ceramic based on 3D printing

A fluorescent ceramic and 3D printing technology, applied in the field of 3D printing, can solve the problems of low material utilization rate, low part precision, high processing cost, etc., achieve uniform light distribution and improve light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

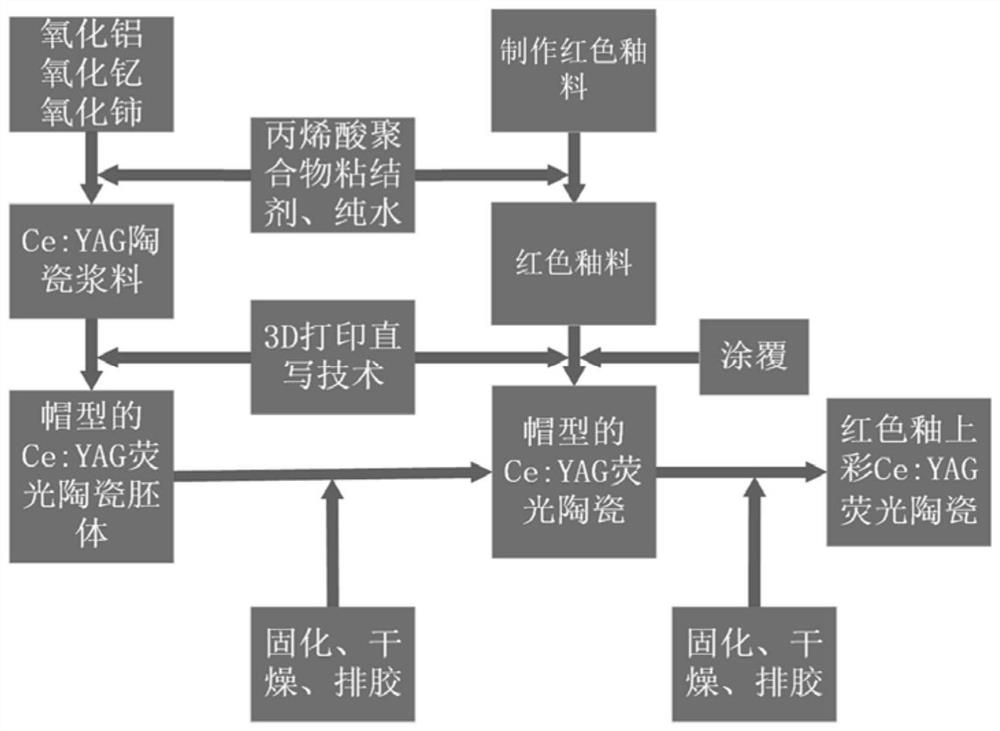

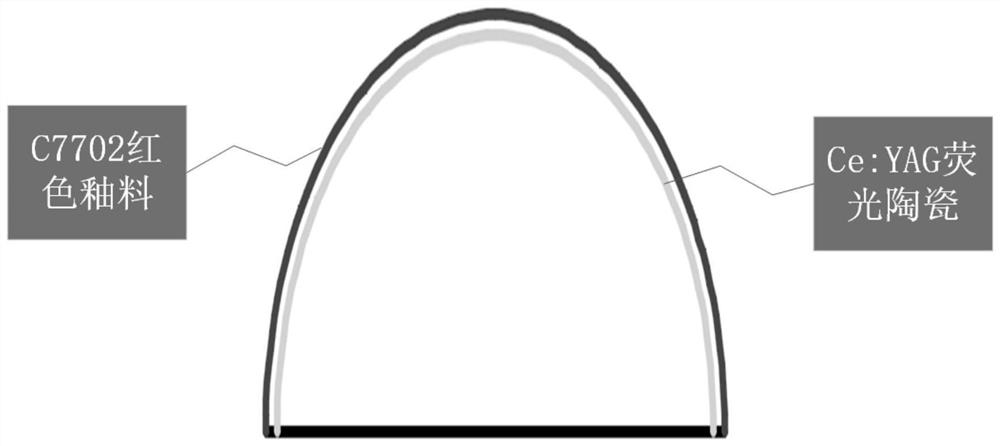

[0032] A kind of preparation method based on 3D printing red overglaze color Ce:YAG fluorescent ceramics, comprises the following steps:

[0033] (1) Prepare 60g of (Y 0.999 Ce 0.001 ) 3 al 5 o 12 Materials, according to the stoichiometric ratio of each element in the chemical formula, respectively weigh alumina, yttrium oxide and cerium oxide ceramic powder to prepare Ce:YAG ceramic powder;

[0034] (2) After fully mixing the above Ce:YAG ceramic powder with binder and pure water, it is made into Ce:YAG ceramic slurry for 3D printing; the binder is an acrylic polymer binder, and Ce : The mass ratio of YAG ceramic powder to acrylic polymer binder and pure water is 1:2:6;

[0035] (3) Print the above ceramic slurry into a cap-shaped Ce:YAG fluorescent ceramic body using 3D printing direct writing technology;

[0036] (4) Place the printed Ce:YAG fluorescent ceramic body at 20°C for natural curing for 6 h, and then carry out drying and debinding treatment on the cured cera...

Embodiment 2

[0040] A kind of preparation method based on 3D printing red overglaze color Ce:YAG fluorescent ceramics, comprises the following steps:

[0041] (1) Prepare 60g of (Y 0.998 Ce 0.002 ) 3 al 5 o 12Materials, according to the stoichiometric ratio of each element in the chemical formula, respectively weigh alumina, yttrium oxide and cerium oxide ceramic powder to prepare Ce:YAG ceramic powder;

[0042] (2) After fully mixing the above Ce:YAG ceramic powder with binder and pure water, it is made into Ce:YAG ceramic slurry for 3D printing; the binder is an acrylic polymer binder, and Ce : The mass ratio of YAG ceramic powder to acrylic polymer binder and pure water is 1:3:7;

[0043] (3) Print the above ceramic slurry into a cap-shaped Ce:YAG fluorescent ceramic body using 3D printing direct writing technology;

[0044] (4) Place the printed Ce:YAG fluorescent ceramic body at 25°C for 7 h to naturally cure, and then carry out drying and debinding treatment on the cured cerami...

Embodiment 3

[0048] (1) Prepare 60g of (Y 0.99 Ce 0.01 ) 3 al 5 o 12 Materials, according to the stoichiometric ratio of each element in the chemical formula, respectively weigh alumina, yttrium oxide and cerium oxide ceramic powder to prepare Ce:YAG ceramic powder;

[0049] (2) After fully mixing the above Ce:YAG ceramic powder with binder and pure water, it is made into Ce:YAG ceramic slurry for 3D printing; the binder is an acrylic polymer binder, and Ce : The mass ratio of YAG ceramic powder to acrylic polymer binder and pure water is 1:4:8;

[0050] (3) Print the above ceramic slurry into a cap-shaped Ce:YAG fluorescent ceramic body using 3D printing direct writing technology;

[0051] (4) Place the printed Ce:YAG fluorescent ceramic body at 30°C for 8 h to naturally cure, and then perform drying and debinding treatment on the cured ceramic body in turn; the drying process is as follows: ℃ for 72 h; then raise the temperature to 80 ℃, and keep for 72 h; the specific steps of deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com