Catalyst for removing carbon monoxide in flue gas and preparation method thereof

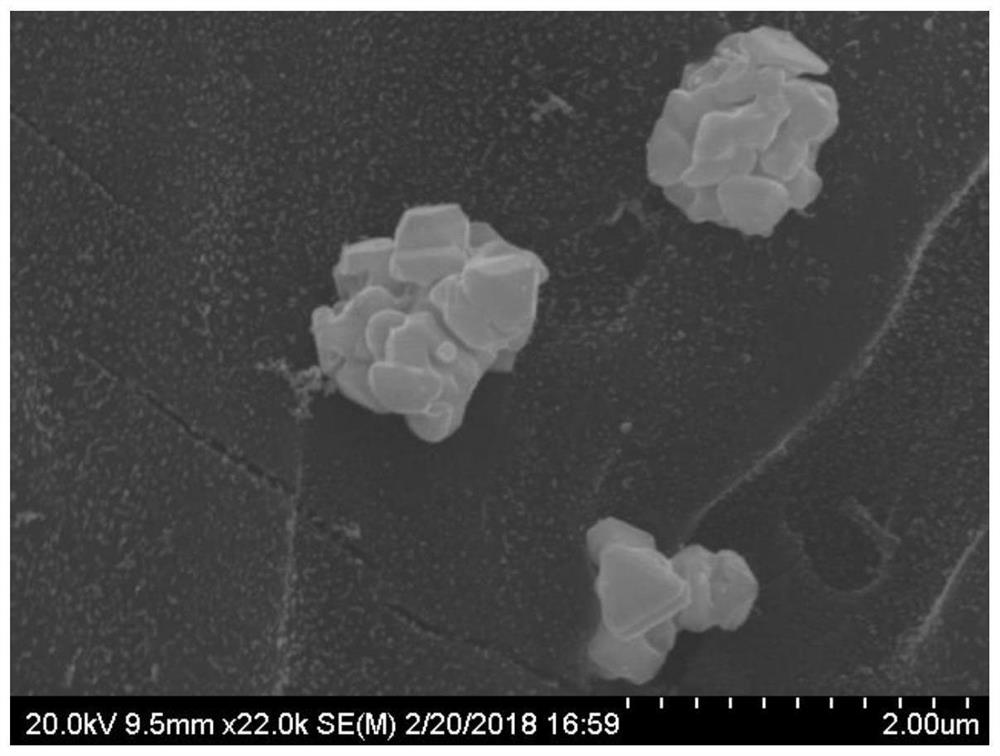

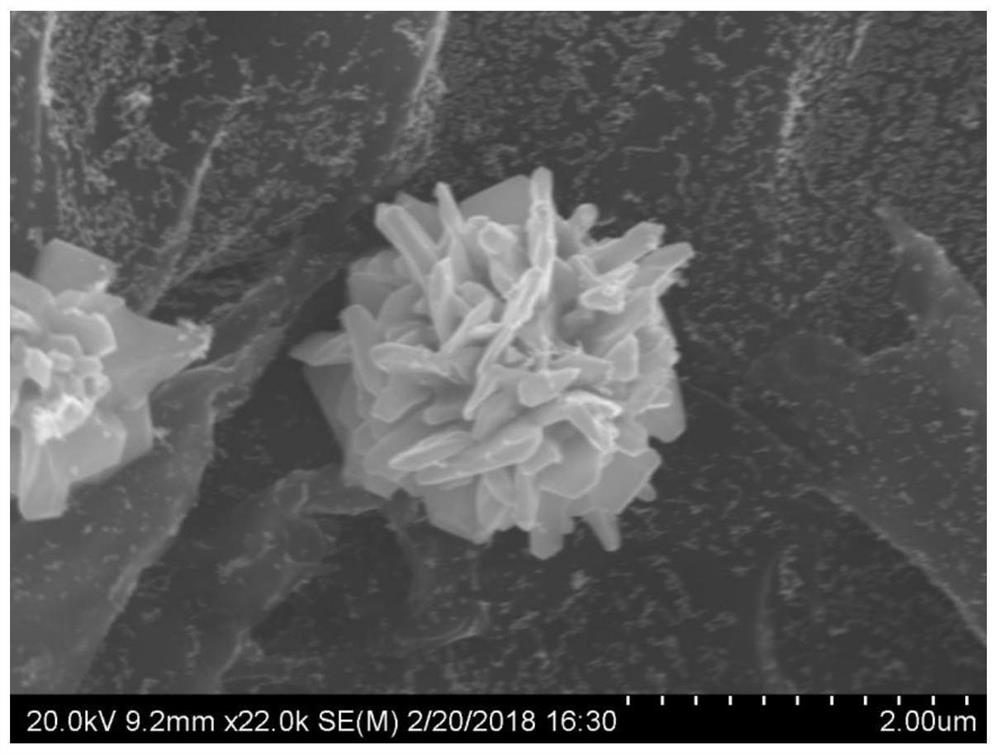

A carbon monoxide and catalyst technology, which is applied in the field of biomass activated carbon-supported gold microflowers to remove carbon monoxide from flue gas and its preparation, can solve the problems of uneven distribution of active components, easy aggregation of gold nanoparticles, and limited catalyst application. Achieve the effects of easy implementation, overcoming high cost, and strong acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Catalyst preparation of the present invention:

[0030] (1) Preparation of active component precursor solution

[0031] Weigh 0.0340g of chloroauric acid, add 1mL of ultrapure water to dissolve and use ultrasonic vibration until the solution is clear and transparent to obtain a chloroauric acid solution with a concentration of 100mM, and take 100μL of the solution as a precursor solution for later use;

[0032] (2) Preparation of carrier

[0033] Weigh 2g of coconut shells with a particle size of 0.25-0.425mm, put them in an atmosphere furnace with nitrogen as a protective atmosphere, and roast at 500°C for 2h to obtain biomass carbon, then weigh 2g of sodium hydroxide, and dissolve it in 5g of ultrapure water After stirring for 12 hours with the biomass carbon obtained by roasting, place it in a blast drying oven at 80°C for heat preservation and drying, then place the biomass carbon adsorbed with NaOH in an atmosphere furnace with nitrogen as a protective atmosphere ...

Embodiment 2

[0043] Catalyst preparation method of the present invention is as follows:

[0044] (1) Preparation of active component precursor solution

[0045] Weigh 0.0340g of chloroauric acid, add 1mL of ultrapure water to dissolve and use ultrasonic vibration until the solution is clear and transparent to obtain a chloroauric acid solution with a concentration of 100mM, and take 200μL of the solution as the precursor solution for later use;

[0046] (2) Preparation of carrier

[0047] Weigh 2g of coconut shells with a particle size of 0.25-0.425mm, put them in an atmosphere furnace with nitrogen as a protective atmosphere, and roast at 500°C for 2h to obtain biomass carbon, then weigh 2g of sodium hydroxide, and dissolve it in 5g of ultrapure water After stirring for 12 hours with the biomass carbon obtained by roasting, place it in a blast drying oven at 80°C for heat preservation and drying, then place the biomass carbon adsorbed with NaOH in an atmosphere furnace with nitrogen as a...

Embodiment 3

[0057] Catalyst preparation method of the present invention is as follows:

[0058] (1) Preparation of active component precursor solution

[0059] Weigh 0.0340g of chloroauric acid, add 1mL of ultrapure water to dissolve and use ultrasonic vibration until the solution is clear and transparent, and obtain a chloroauric acid solution with a concentration of 100mM, and take 300μL of the solution as a precursor solution for later use;

[0060] (2) Preparation of carrier

[0061] Weigh 2g of coconut shells with a particle size of 0.25-0.425mm, put them in an atmosphere furnace with nitrogen as a protective atmosphere, and roast at 500°C for 2h to obtain biomass carbon, then weigh 2g of sodium hydroxide, and dissolve it in 5g of ultrapure water After stirring for 12 hours with the biomass carbon obtained by roasting, place it in a blast drying oven at 80°C for heat preservation and drying, then place the biomass carbon adsorbed with NaOH in an atmosphere furnace with nitrogen as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com