Lateral air supply and return treatment cabinet layout of refrigerator safety performance testing room and method thereof

A technology of air treatment and safety performance, which is applied in the field of return air air treatment cabinets in refrigerator test laboratories, to achieve the effect of meeting wind speed, meeting temperature and humidity requirements, wind speed requirements, and uniform air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

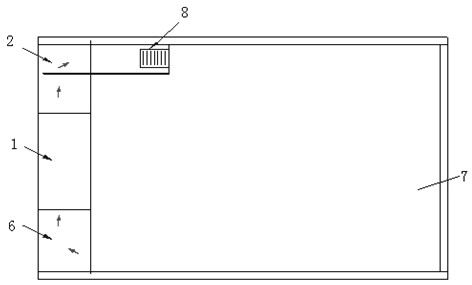

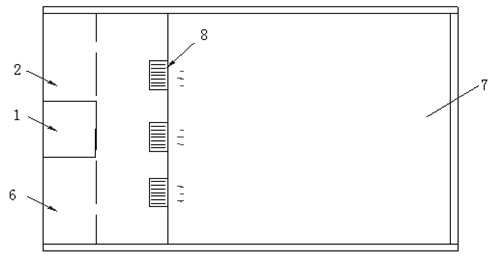

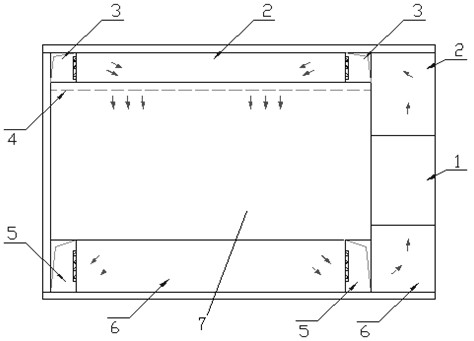

[0017] like image 3 , shown in 4, the side of the refrigerator safety performance testing room of the present invention sends and returns the wind air treatment cabinet layout, comprises air treatment cabinet 1, environmental test room 7, sends and returns air main pipe 2,6, sends and returns air branch pipe 3,5 , air supply orifice 4.

[0018] The air treatment cabinet 1 is installed on the side of the environmental test chamber 7, and the upper and lower air supply and return air main pipes 2, 6 are symmetrically arranged on the upper and lower sides of the environmental test room 7, and the air supply and return air main pipes 2, 6 are respectively connected to the outlet and air inlet of the air treatment cabinet 1 . The air supply and return main pipes 2, 6 are out of the air treatment cabinet 1, and the air supply and return air branch pipes 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com