Optical fiber preform preparation method

An optical fiber preform and liner technology, which is applied to glass manufacturing equipment, manufacturing tools, etc., can solve the problems of complex doping process and uneven distribution, so as to reduce optical fiber attenuation, reduce equipment use costs, and uniform distribution of alkali metal content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

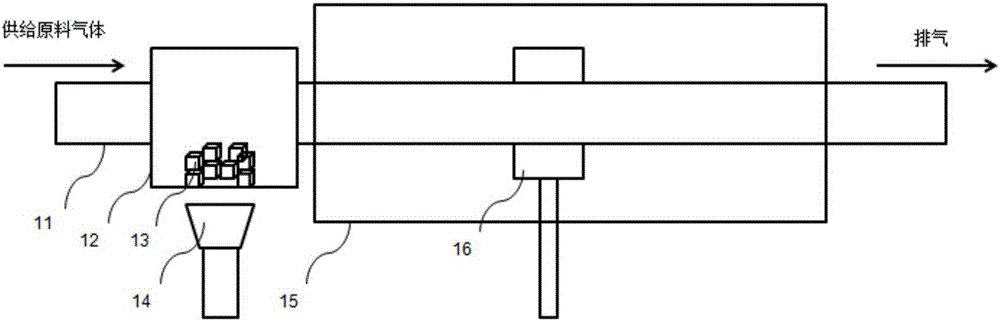

[0031] Such as figure 1 As shown, the optical fiber preform is manufactured through the PCVD deposition process, the holding furnace 15 surrounds the deposition reaction area of the glass liner 11, and the resonant cavity 16 is between the holding furnace 15 and the glass liner 11, and can move left and right on the periphery of the glass liner 11 , to provide a heat source for the deposition reaction area; a large-diameter glass tube 12 is connected in series at the gas inlet end of the glass liner 11, and the two ends of the large-diameter glass tube 12 are respectively connected to the gas inlet pipe and the glass liner 11 by welding, and A heater 14 is installed around the outside of the large-diameter glass tube 12;

[0032] use as figure 1 The device, the method for preparing an optical fiber preform, the steps are as follows:

[0033] 1) Put 5-50g of alkali metal raw material KBr13 in the large-diameter glass tube 12;

[0034] 2) Mandrel cladding deposition: turn o...

Embodiment 2

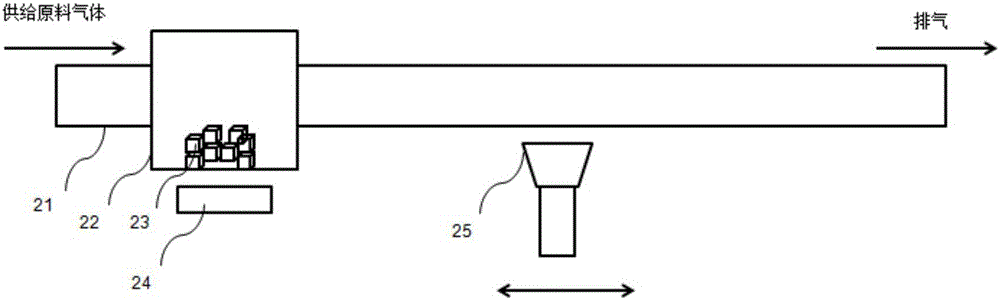

[0041] Such as figure 2 As shown, the optical fiber preform is manufactured by the MCVD deposition process, and the blowtorch 25 can move left and right along the glass liner 21 to provide a heat source for the deposition reaction area; a large diameter glass tube 22 is connected in series at the inlet end of the glass liner 21, and the The two ends of the large-diameter glass tube 22 are respectively connected to the inlet pipe and the glass liner 21 by welding, and a heater 24 is installed around the outside of the large-diameter glass tube 22; the inner diameter of the large-diameter glass tube 22 is greater than that of the glass liner 21 the inside diameter of.

[0042] use as figure 2 The device, the method for preparing an optical fiber preform, the steps are as follows:

[0043] 1) 5-50g of alkali metal raw material NaBr23 is placed in the large-diameter glass tube 22;

[0044] 2) Mandrel cladding deposition: turn off the heater 24, the gas inlet end of the glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com